Seamless pipe is a steel pipe variant

manufactured without any welded joints, hence the name. Seamless pipe has no

seams, reducing the risk of fracture under high pressure and stress. Unlike

welded pipe, seamless pipe has a smoother surface and more uniform diameter.

These characteristics give it exceptional

durability and corrosion resistance. All of these exceptional qualities make it

an ideal choice for the oil and gas industry and the construction industry.

Core Processes of Seamless Steel Pipe

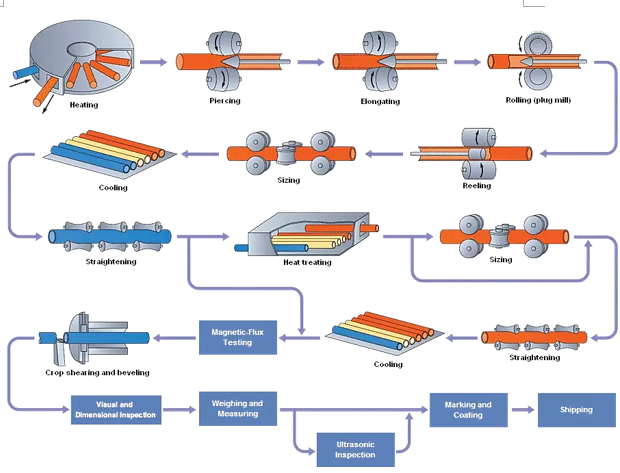

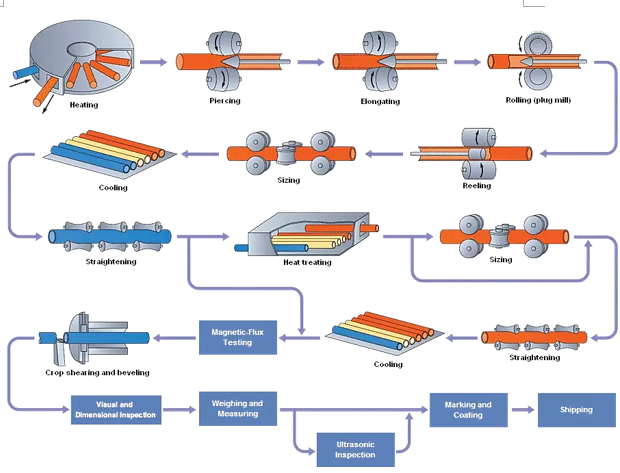

Seamless pipe production begins with a

solid round billet. After being heated to a high temperature, the billet is

rolled into a hollow shell through a piercing mill. This is then rolled through

multiple passes, sizing, and heat treatment to achieve seamless pipes that meet

dimensional and performance requirements.

Core Processes Include:

1. Piercing

Rolling the hot billet into a hollow shell

is the key process that distinguishes seamless pipe from seam

pipe.

2. Rolling and Elongation

The shell is extended through a continuous

rolling mill or a pipe jacking mill to control the outer diameter and wall

thickness.

3. Sizing/Reducing

Further adjusts the pipe diameter to ensure

precise geometric dimensions.

4. Heat Treatment

Improve microstructure and properties,

enhancing toughness, ductility, and corrosion resistance.

Detailed Production Process of Seamless

Pipe

1. Raw Material Selection

Seamless pipe is a durable option for a

wide range of applications. However, to maximize its versatility, it must offer

a variety of processing materials. Raw material selection is key to achieving

the desired pipe properties, including tensile strength, yield strength, and

hardness.

The following are the most commonly used

materials for seamless pipe manufacturing:

Carbon Steel

Commonly used for general-purpose piping,

it offers good strength and weldability. It is suitable for low-pressure

applications such as water, gas, and cryogenic systems.

Alloy Steel

Composed of alloying elements such as

chromium, nickel, and molybdenum. This composition provides increased strength,

toughness, heat resistance, and corrosion resistance.

Stainless Steel

Ensures excellent corrosion resistance and

toughness. It is commonly used in corrosive environments such as marine and

chemical processing.

2. Heating

The steel billet is heated to a high

temperature of 1150°C to 1250°C

to achieve a ductile state. Temperature control is crucial; too low a

temperature can make piercing difficult, while too high a temperature can cause

coarse grains.

3. Extrusion

Industrial rotating tools penetrate the hot

billet, forming a hollow tube shell. The drawing process passes the shell

through a series of heavy rollers, ultimately forming the desired initial shape

and dimensions for the pipe.

4. Expanding

During the expansion process, workers

continuously press a mandrel into the tube. This step is crucial for ensuring a

smooth inner diameter and uniform wall thickness. Mandrel milling involves

continuous rolling and drawing until the desired dimensions are reached.

5. Cooling

The rolled tube billet is cooled in a

controlled environment to prevent cracking caused by thermal stress. Air

cooling or controlled cooling is often used to maintain uniform microstructure.

6. Straightening

Even after cooling, the pipe will still

deform and bend. Therefore, the pipe still needs to pass through rollers or

straighteners to apply controlled pressure to align the pipe. This ensures the

geometric accuracy and usability of the final seamless pipe.

7. Post-Processing

Post-processing may include surface

polishing, threading, or heat treatment to enhance pipe performance. Workers

may also add surface coatings to prevent wear and corrosion.

8. Quality Control

The quality control department inspects

pipes for dimensional accuracy, strength, and surface defects. Safety

inspection mechanisms, including X-ray and ultrasonic testing, ensure the pipes

are free of defects. Pipes undergo final inspection before shipment.

Seamless Steel Pipe Production Craftsmanship

Generally, seamless steel pipe production

processes are divided into cold rolling and hot rolling.

Main production processes (main inspection

processes) for hot-rolled seamless steel pipe:

Pipe Preparation and Inspection → Pipe Heating → Pipe Piercing → Pipe Rolling → Rough Pipe Reheating → Sizing (Reducing) → Heat Treatment → Finished Pipe Straightening → Finishing → Inspection (Non-destructive, Physical and Chemical, Benchtop

Inspection) → Warehousing

Hot-rolled seamless steel pipes are

generally delivered in the hot-rolled state after heat treatment. Hot-rolled

seamless steel pipes undergo rigorous manual selection after quality

inspection. The surface is then oiled and subjected to multiple cold-drawing

tests. After hot-rolling, a perforation test is performed. If the perforation

is too large, the pipes are straightened. After straightening, they are

conveyed by conveyor to a flaw detector for testing. Finally, they are labeled,

sorted according to specifications, and stored.

The main production process for cold-rolled

(drawn) seamless steel pipes is as follows:

Blank preparation → Pickling and lubrication → Cold rolling (drawing) → Heat treatment → Straightening → Finishing → Inspection

The production process for cold-rolled

seamless steel pipes is generally more complex than that for hot-rolled pipes.

If no reaction cracks are observed on the surface during the sizing test, the

round pipe is cut using a cutting machine into blanks approximately one meter

in length. Annealing is then performed, followed by pickling with acid. During

pickling, pay attention to any significant blistering on the surface. If

significant blistering is present, the pipe quality does not meet reaction

standards.

In appearance, cold-rolled seamless steel

pipes are shorter than hot-rolled seamless steel pipes. The wall thickness of

cold-rolled seamless steel pipes is generally thinner than that of hot-rolled

seamless steel pipes. However, the surface of cold-rolled seamless steel pipes

appears much shinier than thick-walled seamless steel pipes, with less

roughness and fewer burrs on the diameter.

Hot-Rolled Seamless Steel Pipe VS.

Cold-Rolled Seamless Steel Pipe

|

Property

|

Hot-Rolled Seamless Pipe

|

Cold-Rolled Seamless Pipe

|

|

Manufacturing Temperature

|

Produced at high temperatures

(>1,000°C)

|

Produced at room temperature or slightly

elevated

|

|

Surface Finish

|

Rough, may have scale

|

Smooth, clean surface, minimal oxidation

|

|

Strength

|

Lower tensile strength and hardness

|

Higher tensile strength, more precise

dimensions

|

|

Cost

|

Less expensive

|

More expensive due to additional

processing

|

|

Applications

|

Heavy-duty, low-precision uses

|

Precision engineering, automotive,

aerospace, pressure vessels

|

Summary

In summary, the production of seamless

steel pipes is a highly sophisticated and complex process, requiring the

coordinated efforts of multiple steps and quality control measures. By strictly

controlling raw material quality, optimizing piercing and rolling processes,

rationally selecting heat treatment methods and finishing processes, and

implementing rigorous inspection and control measures, we can produce

high-quality seamless steel pipes that meet the needs of various industrial

sectors.

Read more: ST52 seamless steel pipe or Seamless steel pipe sizes

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.