Hot rolling is relative to cold

rolling, cold rolling is rolling below the recrystallization temperature,

and hot rolling is rolling above the recrystallization temperature.

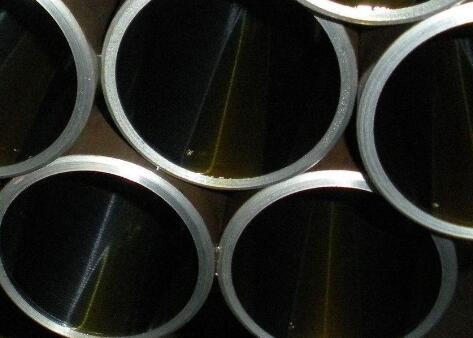

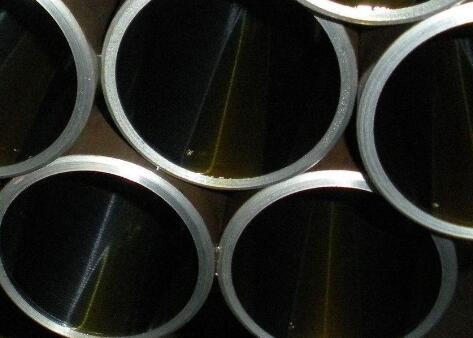

Hot-rolled seamless

steel tubes are made from carbon or alloy steel through

high-temperature rolling and perforation. They typically have an outer diameter

of 32mm or greater and a wall thickness ranging from 2.5mm to 75mm. The

production process includes ingot perforation, hot rolling, and quality

inspection. This process refines the grain size and improves mechanical

properties, making it suitable for applications in construction, machining,

petrochemicals, and fluid transportation.

Hot-rolled seamless steel tubes are

divided into general steel tubes, low- and medium-pressure boiler

steel tubes, high-pressure boiler steel tubes, alloy steel tubes, stainless

steel tubes, petroleum cracking tubes, geological steel tubes and other

steel tubes.

Hot-Rolled Seamless Steel Tube

Production Process

Hot-rolled seamless steel tubes: Round

billet → Heating → Perforation → Three-roller cross-rolling, continuous rolling, or extrusion → Tube stripping → Sizing (or reducing) → Cooling → Billet tube → Straightening → Hydrostatic testing (or

flaw detection) → Marking → Storage.

Materials of Hot-Rolled Seamless Steel

Tubes

Hot-rolled seamless steel tubes are

typically made of carbon steel, alloy steel, and stainless steel.

Carbon steel grades include 20#, 45#, and

Q345B.

Alloy steel grades include 16Mn, 12CrMo,

and 15CrMo.

Stainless steel grades include 304 and 316.

Specifications And Wall Thicknesses of Hot-Rolled

Seamless Steel Tubes

Hot-rolled seamless steel tubes come in a

wide variety of specifications and wall thicknesses, generally classified by

outer diameter and wall thickness.

Common outer diameters range from φ6 to φ720 mm, and wall thicknesses range

from 0.5 to 60 mm.

Hot-rolled seamless steel tubes of varying

specifications and wall thicknesses are suitable for different applications.

Hot-Rolled Seamless Steel Tube Advantage

1. Uniform Wall Thickness

Due to the high temperature and pressure

experienced during the hot rolling process, the steel pipe achieves a more

uniform wall thickness.

2. Smooth Internal and External Surfaces

The smooth internal and external surfaces

of hot-rolled seamless steel tubes reduce fluid resistance in the pipe.

3. Precise Dimensions

The precise dimensions of hot-rolled

seamless steel tubes meet the requirements of various industrial applications.

4. High-Temperature and Pressure Resistance

Hot-rolled seamless steel tubes offer

excellent high-temperature and pressure resistance, making them suitable for

use in high-temperature and high-pressure environments.

Hot-Rolled Seamless Steel Tube

Disadvantage

1. Delamination Occurs

After hot rolling, the non-metallic

inclusions (mainly sulfides and oxides, as well as silicates) inside the steel

are pressed into thin sheets, and delamination (interlayer) occurs.

Delamination greatly deteriorates the

tensile properties of the steel in the thickness direction, and it is possible

that interlayer tearing may occur when the weld shrinks.

2. Residual Stress Caused by Uneven Cooling

Residual stress is the internal

self-balanced stress without external force. Hot-rolled steel sections of

various cross-sections have such residual stresses.

Generally, the larger the section size of

the steel section, the larger the residual stress. Although the residual stress

is self-balanced, it still has a certain influence on the performance of the

steel member under the action of external force.

For example, it may have adverse effects on

deformation, stability, fatigue resistance, etc.

3. Not Easy to Control in Terms of

Thickness and Edge Width

Since at the beginning, even if the length

and thickness are up to the standard, there will be a certain negative

difference after the final cooling.

The wider the negative difference, the

thicker the thickness, the more obvious the performance.

Therefore, for large-sized steel, the side

width, thickness, length, angle, and sideline of the steel cannot be too

precise.

Quality Control of Hot-Rolled Seamless

Steel Tubes

Ensuring the quality of hot-rolled seamless

steel tubes requires strict control in multiple areas:

1. Raw material control

The chemical composition of the steel

billet must be diverse and meet standard requirements, and the content of

harmful elements must be strictly controlled. Surface quality and internal

defects in the steel billet must also be monitored through testing.

2. Process parameter control

Parameters such as heating temperature,

rolling temperature, deformation, and rolling speed all require precise

control. Any deviation can result in substandard product performance. Modern

production lines typically utilize automated control systems to ensure process

stability.

3. Finished product inspection

Hot-rolled seamless steel tubes undergo

multiple tests before leaving the factory, including dimensional measurement,

surface inspection, ultrasonic testing, hydrostatic testing, and mechanical

property testing. Only products that pass all inspections are released.

In addition to routine testing, some

seamless steel pipes for special applications require additional testing, such

as low-temperature impact testing, intergranular corrosion testing, and

non-destructive testing, to meet the requirements of specific operating

environments.

Many may wonder what the difference is

between hot-rolled and cold-rolled seamless tubes. In reality, the primary

difference lies in the production process and final performance:

1. Production Process

Hot rolling is performed at high

temperatures, while cold rolling is performed at room temperature or lower.

2. Surface Quality

Cold-rolled tubes have a smoother surface

and higher dimensional accuracy, but hot-rolled pipes have greater toughness.

3. Cost

The hot-rolling process is relatively

simple, resulting in lower production costs and suitable for large-scale

production.

How to Choose the Right Hot-rolled Seamless

Tube?

In actual purchasing, consumers may face

the dilemma of how to choose. The following factors are worth considering:

1. Material

Different steel pipe materials, such as

ordinary carbon steel, alloy steel, or stainless steel, are suitable for

different environments, and the choice should be based on specific needs.

2. Dimensional Accuracy

If you have strict requirements for pipe

diameter and wall thickness, you should prioritize manufacturers with strong

quality control.

3. Price

The price of hot-rolled seamless tube is

affected by raw materials, processing technology, and market supply and demand.

We recommend choosing products with the best value for money within your

budget.

Read more: Difference Between Cold-drawn & Hot-rolled Seamless Steel Pipe or Infolding of hot rolled seamless steel pipes

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.