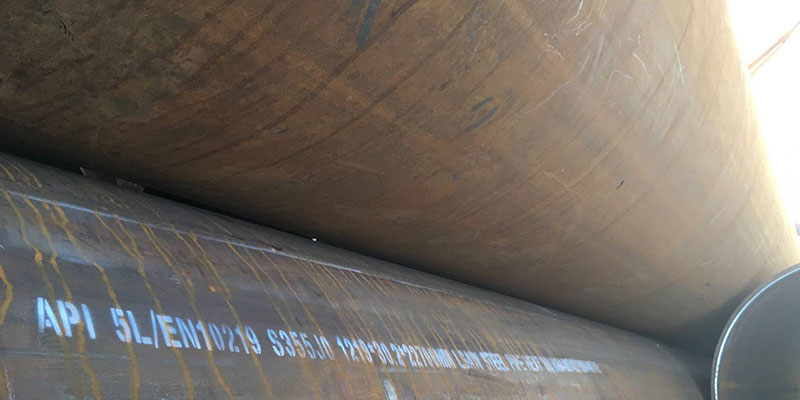

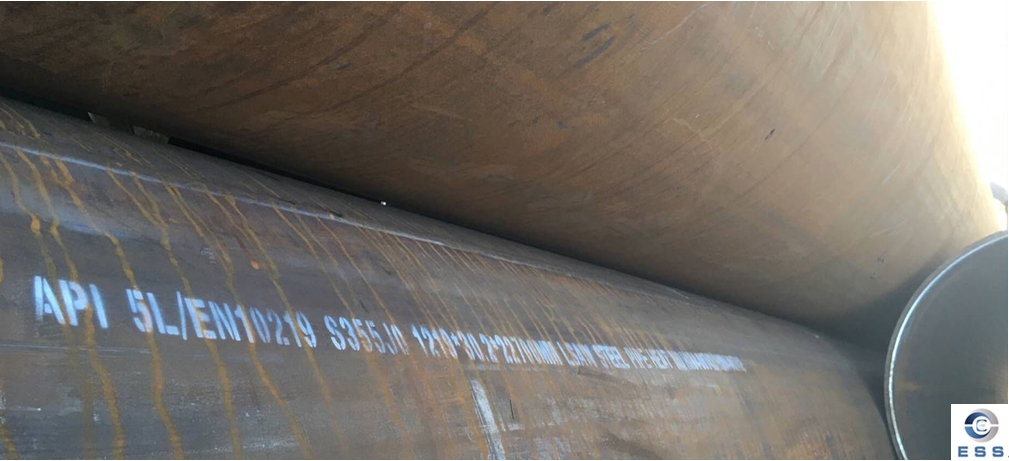

Longitudinally Submerged Arc Welding Pipe is subdivided into UOE, RBE, JCOE steel pipe according to its different forming methods. Longitudinal high-frequency welded steel pipe has the characteristics of relatively simple process and fast continuous production, and has wide use in civil construction, petrochemical, light industry and other sectors. Mostly used to transport low pressure fluids or made into various engineering components and light industrial products.

|

Products

|

UOE LSAW PIPES

|

JCOE LSAW PIPES

|

Outside Diameter

|

Φ508mm- 1118mm (20"- 44")

|

Φ406mm- 1626mm (16" - 64" )

|

Wall Thickness

|

6.0-25.4mm 1/4"-1"

|

6.0- 75mm (1/4" - 3" )

|

Length

|

9-12.3m (30'- 40')

|

3-12.5m ( 10"- 41")

|

Quality Standards

|

API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

|

API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

|

Grades

|

API 5L A-X90,GB/T9711 L190-L625

|

API 5L A-X100, GB/T9711 L190-L690

|

|

Tolerance of Outside Diameter and Wall Thickness

|

|

Types

|

Standard

|

|

SY/T5040-2000

|

SY/T5037-2000

|

SY/T9711.1-1977

|

ASTM A252

|

AWWA C200-97

|

API 5L PSL1

|

|

OD deviation

|

±0.5%D

|

±0.5%D

|

-0.79mm~+2.38mm

|

<±0.1%T

|

<±0.1%T

|

±1.6mm

|

|

Wall thickness

|

±10.0%T

|

D<508mm, ±12.5%T

|

-8%T~+19.5%T

|

<-12.5%T

|

-8%T~+19.5%T

|

5.0mm

|

|

D>508mm, ±10.0%T

|

T≥15.0mm, ±1.5mm

|

|

Chemical Composition & Mechanical Properties

|

|

Standard

|

Grade

|

Chemical Composition

(max)%

|

Mechanical Properties

(min)

|

|

C

|

Mn

|

Si

|

S

|

P

|

Yield Strength

|

Tensile Strength

|

|

(Mpa)

|

(Mpa)

|

|

GB/T700-2006

|

A

|

0.22

|

1.4

|

0.35

|

0.05

|

0.045

|

235

|

370

|

|

B

|

0.2

|

1.4

|

0.35

|

0.045

|

0.045

|

235

|

370

|

|

C

|

0.17

|

1.4

|

0.35

|

0.04

|

0.04

|

235

|

370

|

|

D

|

0.17

|

1.4

|

0.35

|

0.035

|

0.035

|

235

|

370

|

|

GB/T1591-2009

|

A

|

0.2

|

1.7

|

0.5

|

0.035

|

0.035

|

345

|

470

|

|

B

|

0.2

|

1.7

|

0.5

|

0.03

|

0.03

|

345

|

470

|

|

C

|

0.2

|

1.7

|

0.5

|

0.03

|

0.03

|

345

|

470

|

|

BS En10025

|

S235JR

|

0.17

|

1.4

|

-

|

0.035

|

0.035

|

235

|

360

|

|

S275JR

|

0.21

|

1.5

|

-

|

0.035

|

0.035

|

275

|

410

|

|

S355JR

|

0.24

|

1.6

|

-

|

0.035

|

0.035

|

355

|

470

|

|

DIN 17100

|

ST37-2

|

0.2

|

-

|

-

|

0.05

|

0.05

|

225

|

340

|

|

ST44-2

|

0.21

|

-

|

-

|

0.05

|

0.05

|

265

|

410

|

|

ST52-3

|

0.2

|

1.6

|

0.55

|

0.04

|

0.04

|

345

|

490

|

|

JIS G3101

|

SS400

|

-

|

-

|

-

|

0.05

|

0.05

|

235

|

400

|

|

SS490

|

-

|

-

|

-

|

0.05

|

0.05

|

275

|

490

|

|

API 5L PSL1

|

A

|

0.22

|

0.9

|

-

|

0.03

|

0.03

|

210

|

335

|

|

B

|

0.26

|

1.2

|

-

|

0.03

|

0.03

|

245

|

415

|

|

X42

|

0.26

|

1.3

|

-

|

0.03

|

0.03

|

290

|

415

|

|

X46

|

0.26

|

1.4

|

-

|

0.03

|

0.03

|

320

|

435

|

|

X52

|

0.26

|

1.4

|

-

|

0.03

|

0.03

|

360

|

460

|

|

X56

|

0.26

|

1.1

|

-

|

0.03

|

0.03

|

390

|

490

|

|

X60

|

0.26

|

1.4

|

-

|

0.03

|

0.03

|

415

|

520

|

|

X65

|

0.26

|

1.45

|

-

|

0.03

|

0.03

|

450

|

535

|

|

X70

|

0.26

|

1.65

|

-

|

0.03

|

0.03

|

585

|

570

|

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.