Flanges are interconnecting parts between pipes and tubes, used to connect between pipe ends,the main features of flange connection are easy disassembly and good sealing performance.

Carbon Steel Flange: ASTM A 105

Stainless Steel Flange: ASTM A 182

Size: 1/2”-60” (DN15-DN3000)

Pressure class: Class150-Class2500

Facing: RF/ FM/ M/ T G/ RF / FF / RTJ

Application: Water Supply, Oil, Gas, Petrochemical, Irrigation, Fire Services, General Industry, Construction.

Marking: All Flanges when possible will display a heat number, size, table, grade and dimensional standard

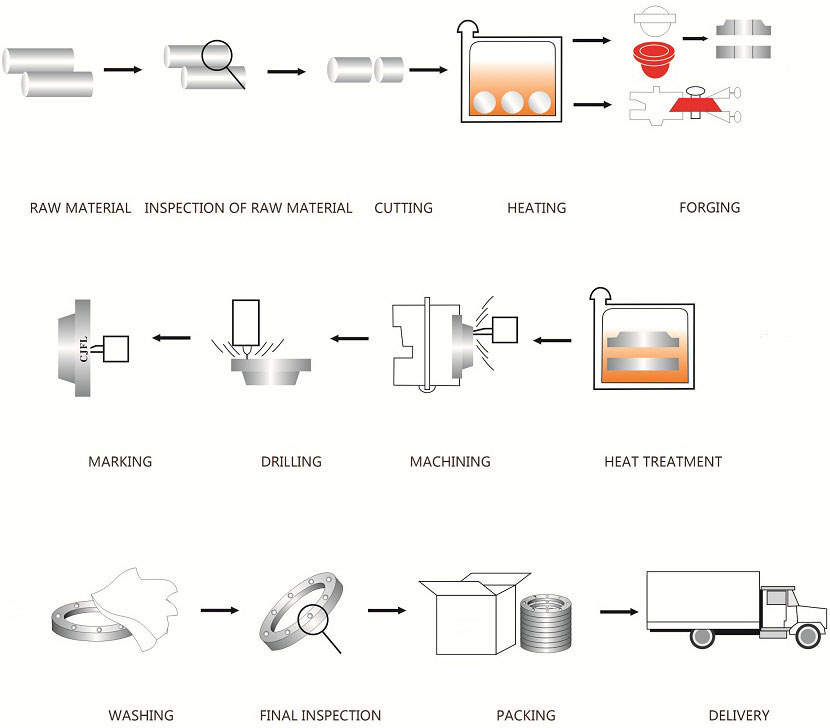

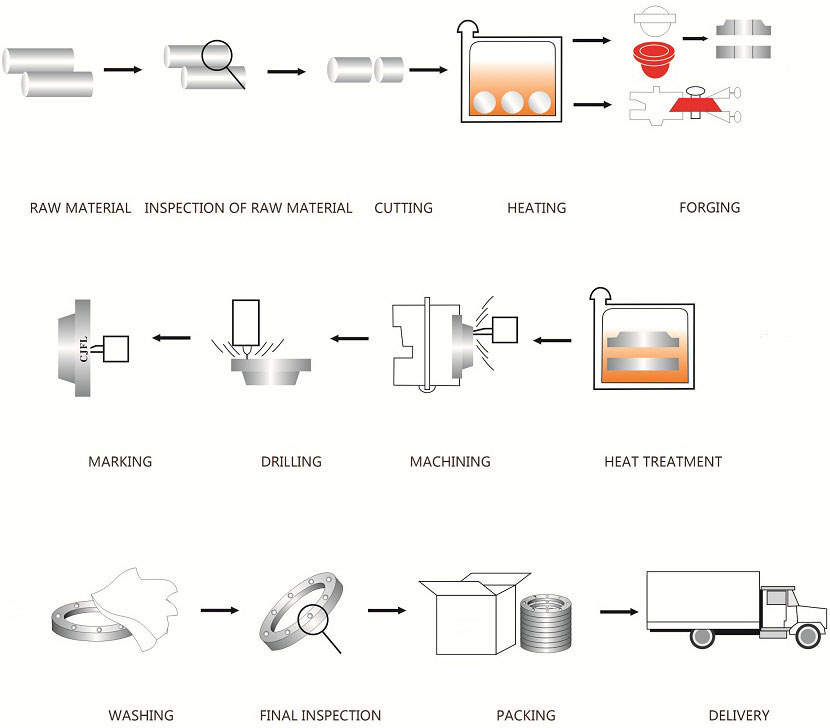

Plate steel flange: Plate flanges are mainly used for light duty, lower pressure or non-critical applications, commonly referring to AS2129, BS10 or AS4087 standards. The manufacturing method involves cutting and machining from plate steel

Forged steel flange: Forged Steel flanges are commonly used and specified in the Oil, Gas, Petrochemical and mining sectors, where pressure, temperature and safety considerations often specify the ANSI B16.5, ASME B16.47 or BS4504 standards. The manufacturing method involves the hot forging of suitable steels prior to final machining

BLIND FLANGES

Blind flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for blind flanges, the standard height is 1/16" for blind flanges under 400#. For blind flanges of 400# and up, the standard blind flange raised face height is 1/4".

Material: Carbon, Alloy and Stainless Steel

Standards: ASTM A105, ASTM A182

Sizes: 1/2'' to 24'', Customized up to 48''

Thickness: Schedule 10(S) to SCH 160

Pressure Ratings: Class 150 to 2500

Face Type: RF, RTJ

|

SLIP-ON FLANGES

Slip on pipe flanges are typically provided with a raised or flat face. When a raised face is necessary for slip on pipe flanges, the standard height is 1/16" for slip on pipe flanges under 400#. For slip on pipe flanges of 400# and up, the standard slip on pipe flange raised face height is 1/4".

Standard: ASTM A105, ASTM A182

Material: Carbon Steel, Alloy Steel, Stainless Steel

Size: 1/2'' to 24'', customized up to 60''

Pressure Ratings: Class 150 to Class 2500

Face Type: RF, RTJ

|

WELD NECK FLANGES

Weld neck pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for weld neck pipe flanges, the standard height is 1/16" for weld neck pipe flanges under 400#. For weld neck pipe flanges of 400# and up, the standard weld neck pipe flange raised face height is 1/4".

Material: Carbon, Alloy and Stainless Steel

Standards: ASTM A105, ASTM A182

Sizes: 1/2'' to 24'', Customized up to 48''

Thickness: Schedule 10(S) to SCH 160

Pressure Ratings: Class 150 to 2500

Face Type: RF, RTJ

|

LAP JOINT FLANGES

Slip on Pipe flanges with a hub have published specifications that range from 1/2" thru 24". Sizes above 24" are produced as lap joints to slip on dimensions. Coastal Flange provides Lap Joint pipe flanges in all material grades, specifications and sizes.

Carbon steel: ASTM A105, A350 LF2

Stainless steel: A182 F304/F304L/F316/F316L/F321

Alloy steel: ASTM A182, GR F1, F11, F22, F5, F9, F91

Outer Diameters: 1/2'' to 24''

Wall Thickness Schedule: SCH 10, SCH 40, SCH 160

|

THREADED FLANGES

Threaded pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for threaded pipe flanges, the standard height is 1/16" for threaded pipe flanges under 400#. For threaded pipe flanges of 400# and up, the standard threaded pipe flange raised face height is 1/4".

Standard: ASTM A105, ASTM A182

Material: Carbon Steel, Stainless Steel, Alloy Steel

Size Range: 1/2'', 1'', 2'', 3'', 4'' to 24''

Pressure Class: Class 150 to 2500

Face: Raised face (RF), Ring type joint (RTJ)

|

SOCKET WELD FLANGES

Socket Weld pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for socket weld pipe flanges, the standard height is 1/16" for socket weld pipe flanges under 400#. For socket weld pipe flanges of 400# and up, the standard socket weld pipe flange raised face height is 1/4".

Standard:

Carbon steel ASTM A105, ASTM A350 LF1/2, ASTM A181

Alloy steel ASTM A182 F5, F9, F11, F22, F91

Stainless steel ASTM A182 F304/L, F316/L

Outer Diameters: 1/2 inch to 24 inch, up to 2500#

Special made: 24'' to 60'', up to 900#

Wall Thickness: Schedule 40 to 160

Pressure Ratings: Class 150 to Class 2500

Face Type: RF, RTJ

|

CLASS 150According to ASTM A/SA-105; ANSI B16.5

|

|

Nominal

Pipe

Size

|

Outside

Diam. of

Flange (O)

|

Thick.

of

Flange (C)

|

Diam.

of

Raised Face (R)

|

Diam.

of Hub

at Base (X)

|

Length

thru Hub

(Y)

|

Min.

Thread

Length

(T)

|

Min.

Counter

Bore (Q)

|

No. of

Holes

|

Diam. of

Holes

|

Diam. of

Bolts

|

Diam.

of Bolt

Circle

|

Approx.

Weight

(in Pounds)

|

|

½

|

3.5

|

0.44

|

1.38

|

1.19

|

0.62

|

0.62

|

|

4

|

0.62

|

0.5

|

2.38

|

1

|

|

¾

|

3.88

|

0.5

|

1.69

|

1.5

|

0.62

|

0.62

|

|

4

|

0.62

|

0.5

|

2.75

|

2

|

|

1

|

4.25

|

0.56

|

2

|

1.94

|

0.69

|

0.69

|

|

4

|

0.62

|

0.5

|

3.12

|

2

|

|

1 ¼

|

4.62

|

0.62

|

2.5

|

2.31

|

0.81

|

0.81

|

|

4

|

0.62

|

0.5

|

3.5

|

3

|

|

1 ½

|

5

|

0.69

|

2.88

|

2.56

|

0.88

|

0.88

|

|

4

|

0.62

|

0.5

|

3.88

|

3

|

|

2

|

6

|

0.75

|

3.62

|

3.06

|

1

|

1

|

|

4

|

0.75

|

0.62

|

4.75

|

5

|

|

2 ½

|

7

|

0.88

|

4.12

|

3.56

|

1.12

|

1.12

|

|

4

|

0.75

|

0.62

|

5.5

|

7

|

|

3

|

7.5

|

0.94

|

5

|

4.25

|

1.19

|

1.19

|

|

4

|

0.75

|

0.62

|

6

|

8

|

|

3 ½

|

8.5

|

0.94

|

5.5

|

4.81

|

1.25

|

1.25

|

|

8

|

0.75

|

0.62

|

7

|

11

|

|

4

|

9

|

0.94

|

6.19

|

5.31

|

1.31

|

1.31

|

|

8

|

0.75

|

0.62

|

7.5

|

13

|

|

5

|

10

|

0.94

|

7.31

|

6.44

|

1.44

|

1.44

|

|

8

|

0.88

|

0.75

|

8.5

|

15

|

|

6

|

11

|

1

|

8.5

|

7.56

|

1.56

|

1.56

|

|

8

|

0.88

|

0.75

|

9.5

|

19

|

|

8

|

13.5

|

1.12

|

10.62

|

9.69

|

1.75

|

1.75

|

|

8

|

0.88

|

0.75

|

11.75

|

30

|

|

10

|

16

|

1.19

|

12.75

|

12

|

1.94

|

1.94

|

|

12

|

1

|

0.88

|

14.25

|

43

|

|

12

|

19

|

1.25

|

15

|

14.38

|

2.19

|

2.19

|

|

12

|

1

|

0.88

|

17

|

64

|

|

14

|

21

|

1.38

|

16.25

|

15.75

|

2.25

|

2.25

|

|

12

|

1.12

|

1

|

18.75

|

90

|

|

16

|

23.5

|

1.44

|

18.5

|

18

|

2.5

|

2.5

|

|

16

|

1.12

|

1

|

21.25

|

98

|

|

18

|

25

|

1.56

|

21

|

19.88

|

2.69

|

2.69

|

|

16

|

1.25

|

1.13

|

22.75

|

130

|

|

20

|

27.5

|

1.69

|

23

|

22

|

2.88

|

2.88

|

|

20

|

1.25

|

1.12

|

25

|

165

|

|

24

|

32

|

1.88

|

27.25

|

26.12

|

3.25

|

3.25

|

|

20

|

1.38

|

1.25

|

29.5

|

220

|

|

CLASS 300According to ASTM A/SA-105; ANSI B16.5

|

|

Nominal

Pipe

Size

|

Outside

Diam. of

Flange (O)

|

Thick.

of

Flange (C)

|

Diam.

of

Raised Face

(R)

|

Diam.

of Hub

at Base

(X)

|

Length

thru Hub

(Y)

|

Min.

Thread

Length

(T)

|

Min.

Counter Bore

(Q)

|

No. of

Holes

|

Diam. of

Holes

|

Diam.

of Bolts

|

Diam.

of Bolt

Circle

|

Approx.

Weight

(in Pounds)

|

|

1/2

|

3.75

|

0.56

|

1.38

|

1.5

|

0.88

|

0.62

|

0.93

|

4

|

0.62

|

0.5

|

2.62

|

2

|

|

3/4

|

4.62

|

0.62

|

1.69

|

1.88

|

1

|

0.62

|

1.14

|

4

|

0.75

|

0.62

|

3.25

|

3

|

|

1

|

4.88

|

0.69

|

2

|

2.12

|

1.06

|

0.69

|

1.41

|

4

|

0.75

|

0.62

|

3.5

|

3

|

|

1 1/4

|

5.25

|

0.75

|

2.5

|

2.5

|

1.06

|

0.81

|

1.75

|

4

|

0.75

|

0.62

|

3.88

|

4

|

|

1 1/2

|

6.12

|

0.81

|

2.88

|

2.75

|

1.19

|

0.88

|

1.99

|

4

|

0.88

|

0.75

|

4.5

|

6

|

|

2

|

6.5

|

0.88

|

3.62

|

3.31

|

1.31

|

1.12

|

2.5

|

8

|

0.75

|

0.62

|

5

|

7

|

|

2 1/2

|

7.5

|

1

|

4.12

|

3.94

|

1.5

|

1.25

|

3

|

8

|

0.88

|

0.75

|

5.88

|

10

|

|

3

|

8.25

|

1.12

|

5

|

4.62

|

1.69

|

1.25

|

3.63

|

8

|

0.88

|

0.75

|

6.62

|

13

|

|

3 1/2

|

9

|

1.19

|

5.5

|

5.25

|

1.75

|

1.44

|

4.13

|

8

|

0.88

|

0.75

|

7.25

|

17

|

|

4

|

10

|

1.25

|

6.19

|

5.75

|

1.88

|

1.44

|

4.63

|

8

|

0.88

|

0.75

|

7.88

|

22

|

|

5

|

11

|

1.38

|

7.31

|

7

|

2

|

1.69

|

5.69

|

8

|

0.88

|

0.75

|

9.25

|

28

|

|

6

|

12.5

|

1.44

|

8.5

|

8.12

|

2.06

|

1.81

|

6.75

|

12

|

0.88

|

0.75

|

10.62

|

39

|

|

8

|

15

|

1.62

|

10.62

|

10.25

|

2.44

|

2

|

8.75

|

12

|

1

|

0.88

|

13

|

58

|

|

10

|

17.5

|

1.88

|

12.75

|

12.62

|

2.62

|

2.19

|

10.88

|

16

|

1.12

|

1

|

15.25

|

81

|

|

12

|

20.5

|

2

|

15

|

14.75

|

2.88

|

2.38

|

12.94

|

16

|

1.25

|

1.12

|

17.75

|

115

|

|

14

|

23

|

2.12

|

16.25

|

16.75

|

3

|

2.5

|

14.19

|

20

|

1.25

|

1.12

|

20.25

|

165

|

|

16

|

25.5

|

2.25

|

18.5

|

19

|

3.25

|

2.69

|

16.19

|

20

|

1.38

|

1.25

|

22.5

|

190

|

|

18

|

28

|

2.38

|

21

|

21

|

3.5

|

2.75

|

18.19

|

24

|

1.38

|

1.25

|

24.75

|

250

|

|

20

|

30.5

|

2.5

|

23

|

23.12

|

3.75

|

2.88

|

20.19

|

24

|

1.38

|

1.25

|

27

|

315

|

|

24

|

36

|

2.75

|

27.25

|

27.62

|

4.19

|

3.25

|

24.19

|

24

|

1.62

|

1.5

|

32

|

475

|

|

CLASS 600According to ASTM A/SA-105; ANSI B16.5

|

|

Nominal

Pipe

Size

|

Outside

Diam. of

Flange (O)

|

Thick.

of

Flange

(C)

|

Diam.

of

Raised Face

(R)

|

Diam.

of Hub

at Base (X)

|

Length

thru Hub

(Y)

|

Min.

Thread

Length

(T)

|

Min.

Counter

Bore

(Q)

|

No. of

Holes

|

Diam. of

Holes

|

Diam. of

Bolts

|

Diam. of

Bolt Circle

|

Approx.

Weight

(in Pounds)

|

|

1/2

|

3.75

|

0.56

|

1.38

|

1.5

|

0.88

|

0.62

|

0.93

|

4

|

0.62

|

0.5

|

2.62

|

2

|

|

3/4

|

4.62

|

0.62

|

1.69

|

1.88

|

1

|

0.62

|

1.14

|

4

|

0.75

|

0.62

|

3.25

|

3

|

|

1

|

4.88

|

0.69

|

2

|

2.12

|

1.06

|

0.69

|

1.41

|

4

|

0.75

|

0.62

|

3.5

|

4

|

|

1 1/4

|

5.25

|

0.81

|

2.5

|

2.5

|

1.12

|

0.81

|

1.75

|

4

|

0.75

|

0.62

|

3.88

|

5

|

|

1 1/2

|

6.12

|

0.88

|

2.88

|

2.75

|

1.25

|

0.88

|

1.99

|

4

|

0.88

|

0.75

|

4.5

|

7

|

|

2

|

6.5

|

1

|

3.62

|

3.31

|

1.44

|

1.12

|

2.5

|

8

|

0.75

|

0.62

|

5

|

9

|

|

2 1/2

|

7.5

|

1.12

|

4.12

|

3.94

|

1.62

|

1.25

|

3

|

8

|

0.88

|

0.75

|

5.88

|

13

|

|

3

|

8.25

|

1.25

|

5

|

4.62

|

1.81

|

1.38

|

3.63

|

8

|

0.88

|

0.75

|

6.62

|

16

|

|

3 1/2

|

9

|

1.38

|

5.5

|

5.25

|

1.94

|

1.56

|

4.13

|

8

|

1

|

0.88

|

7.25

|

21

|

|

4

|

10.75

|

1.5

|

6.19

|

6

|

2.12

|

1.62

|

4.63

|

8

|

1

|

0.88

|

8.5

|

37

|

|

5

|

13

|

1.75

|

7.31

|

7.44

|

2.38

|

1.88

|

5.69

|

8

|

1.12

|

1

|

10.5

|

63

|

|

6

|

14

|

1.88

|

8.5

|

8.75

|

2.62

|

2

|

6.75

|

12

|

1.12

|

1

|

11.5

|

80

|

|

8

|

16.5

|

2.19

|

10.62

|

10.75

|

3

|

2.25

|

8.75

|

12

|

1.25

|

1.12

|

13.75

|

115

|

|

10

|

20

|

2.5

|

12.75

|

13.5

|

3.38

|

2.56

|

10.88

|

16

|

1.38

|

1.25

|

17

|

170

|

|

12

|

22

|

2.62

|

15

|

15.75

|

3.62

|

2.75

|

12.94

|

20

|

1.38

|

1.25

|

19.25

|

200

|

|

14

|

23.75

|

2.75

|

16.25

|

17

|

3.69

|

2.88

|

14.19

|

20

|

1.5

|

1.38

|

20.75

|

230

|

|

16

|

27

|

3

|

18.5

|

19.5

|

4.19

|

3.06

|

16.19

|

20

|

1.62

|

1.5

|

23.75

|

330

|

|

18

|

29.25

|

3.25

|

21

|

21.5

|

4.62

|

3.12

|

18.19

|

20

|

1.75

|

1.63

|

25.75

|

400

|

|

20

|

32

|

3.5

|

23

|

24

|

5

|

3.25

|

20.19

|

24

|

1.75

|

1.62

|

28.5

|

510

|

|

24

|

37

|

4

|

27.25

|

28.25

|

5.5

|

3.62

|

24.19

|

24

|

2

|

1.88

|

33

|

730

|

|

CLASS 900According to ASTM A/SA-105; ANSI B16.5

|

|

Nominal

Pipe

Size

|

Outside

Diam. of

Flange (O)

|

Thick.

of

Flange

(C)

|

Diam.

of

Raised Face

(R)

|

Diam.

of Hub

at Base

(X)

|

Length

thru Hub (Y)

|

Min.

Thread

Length

(T)

|

Min.

Counter

Bore

(Q)

|

No. of

Holes

|

Diam. of

Holes

|

Diam. of

Bolts

|

Diam. of

Bolt Circle

|

Approx.

Weight

(in Pounds)

|

|

1/2

|

4.75

|

0.88

|

1.38

|

1.5

|

1.25

|

0.88

|

0.93

|

4

|

0.88

|

0.75

|

3.25

|

4

|

|

3/4

|

5.12

|

1

|

1.69

|

1.75

|

1.38

|

1

|

1.14

|

4

|

0.88

|

0.75

|

3.5

|

5

|

|

1

|

5.88

|

1.12

|

2

|

2.06

|

1.62

|

1.12

|

1.41

|

4

|

1

|

0.88

|

4

|

8

|

|

1 1/4

|

6.25

|

1.12

|

2.5

|

2.5

|

1.62

|

1.19

|

1.75

|

4

|

1

|

0.88

|

4.38

|

9

|

|

1 1/2

|

7

|

1.25

|

2.88

|

2.75

|

1.75

|

1.25

|

1.99

|

4

|

1.12

|

1

|

4.88

|

12

|

|

2

|

8.5

|

1.5

|

3.62

|

4.12

|

2.25

|

1.5

|

2.5

|

8

|

1

|

0.88

|

6.5

|

25

|

|

2 1/2

|

9.62

|

1.62

|

4.12

|

4.88

|

2.5

|

1.88

|

3

|

8

|

1.12

|

1

|

7.5

|

36

|

|

3

|

9.5

|

1.5

|

5

|

5

|

2.12

|

1.62

|

3.63

|

8

|

1

|

0.88

|

7.5

|

26

|

|

4

|

11.5

|

1.75

|

6.19

|

6.25

|

2.75

|

1.88

|

4.63

|

8

|

1.25

|

1.12

|

9.25

|

53

|

|

5

|

13.75

|

2

|

7.31

|

7.5

|

3.12

|

2.12

|

5.69

|

8

|

1.38

|

1.25

|

11

|

83

|

|

6

|

15

|

2.19

|

8.5

|

9.25

|

3.38

|

2.25

|

6.75

|

12

|

1.25

|

1.12

|

12.5

|

110

|

|

8

|

18.5

|

2.5

|

10.62

|

11.75

|

4.00

|

2.50

|

8.75

|

12

|

1.5

|

1.38

|

15.5

|

170

|

|

10

|

21.5

|

2.75

|

12.75

|

14.5

|

4.25

|

2.81

|

10.88

|

16

|

1.5

|

1.38

|

18.5

|

245

|

|

12

|

24

|

3.12

|

15

|

16.5

|

4.62

|

3

|

12.94

|

20

|

1.5

|

1.38

|

21

|

325

|

|

14

|

25.25

|

3.38

|

16.25

|

17.75

|

5.12

|

3.25

|

14.19

|

20

|

1.62

|

1.5

|

22

|

400

|

|

16

|

27.75

|

3.5

|

18.5

|

20

|

5.25

|

3.38

|

16.19

|

20

|

1.75

|

1.63

|

24.25

|

425

|

|

18

|

31

|

4

|

21

|

22.25

|

6

|

3.5

|

18.19

|

20

|

2

|

1.88

|

27

|

600

|

|

20

|

33.75

|

4.25

|

23

|

24.5

|

6.25

|

3.62

|

20.19

|

20

|

2.12

|

2

|

29.5

|

730

|

|

24

|

41

|

5.5

|

27.25

|

29.5

|

8

|

4

|

24.19

|

20

|

2.62

|

2.5

|

35.5

|

1400

|

|

CLASS 1500According to ASTM A/SA-105; ANSI B16.5

|

|

Nominal

Pipe

Size

|

Outside

Diam. of

Flange (O)

|

Thick.

of

Flange

(C)

|

Diam.

of

Raised Face

(R)

|

Diam.

of Hub

at Base

(X)

|

Length

thru Hub

(Y)

|

Min.

Thread

Length

(T)

|

Min.

Counter

Bore

(Q)

|

No. of

Holes

|

Diam. of

Holes

|

Diam. of

Bolts

|

Diam. of

Bolt Circle

|

Approx.

Weight

(in Pounds)

|

|

1/2

|

4.75

|

0.88

|

1.38

|

1.5

|

1.25

|

0.88

|

0.93

|

4

|

0.88

|

0.75

|

3.25

|

4

|

|

3/4

|

5.12

|

1

|

1.69

|

1.75

|

1.38

|

1

|

1.14

|

4

|

0.88

|

0.75

|

3.5

|

5

|

|

1

|

5.88

|

1.12

|

2

|

2.06

|

1.62

|

1.12

|

1.41

|

4

|

1

|

0.88

|

4

|

8

|

|

1 1/4

|

6.25

|

1.12

|

2.5

|

2.5

|

1.62

|

1.19

|

1.75

|

4

|

1

|

0.88

|

4.38

|

9

|

|

1 1/2

|

7

|

1.25

|

2.88

|

2.75

|

1.75

|

1.25

|

1.99

|

4

|

1.12

|

1

|

4.88

|

12

|

|

2

|

8.5

|

1.5

|

3.62

|

4.12

|

2.25

|

1.5

|

2.5

|

8

|

1

|

0.88

|

6.5

|

25

|

|

2 1/2

|

9.62

|

1.62

|

4.12

|

4.88

|

2.5

|

1.88

|

3

|

8

|

1.12

|

1

|

7.5

|

36

|

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.