Rectangular tube is a hollow square cross-section lightweight thin-walled steel tube, also known as steel cold-formed profile. It is a square section steel with a square cross-section shape and size made of Q235 hot-rolled or cold-rolled strip or coil as the base material, cold bending and then high-frequency welding. In addition to the thickening of the wall thickness, the corner size and edge straightness of hot-rolled extra thick-walled square tubes reach or even exceed the level of resistance welded cold-formed square tubes. When the bending and torsion strength are the same, the weight is lighter, so it is widely used in manufacturing mechanical parts and engineering structures.

Uses of rectangular tubes

Construction, machinery manufacturing, steel construction projects, shipbuilding, solar power generation brackets, steel structure engineering, power engineering, power plants, agricultural and chemical machinery, glass curtain walls, automobile chassis, airports, etc.

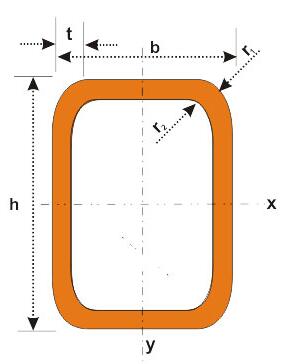

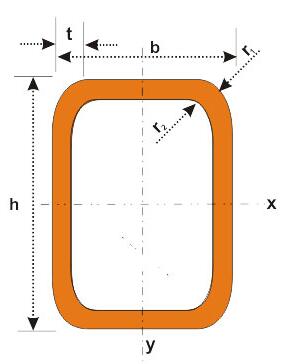

Rectangular Tube are not as common as UC’s and UB’s. This is down to the fact that it is much more difficult to bolts an Rectangular Tube to other beams or to bolt other members to it. Rectangular Tubes are described by their depth, width and wall thickness. An example is a 200 x 100 x 8 RHS, which is 200 mm deep, 100 mm wide and the wall is 8 mm thick. Hot rolled Rectangular Tubes are made at the mill as one piece, whereas cold formed Rectangular Tubes are made of a flat sheet rolled at right angles and welded. It is therefore easy to note the difference, as the cold rolled Rectangular Tubes have a weld all along its length.

Specifications and models of Rectangular Tube

|

Type

|

Weight

[kg/m]

|

Height

[mm]

|

Width

[mm]

|

Wall

thickness

[mm]

|

|

50 x 25 x 2.5

|

2.7

|

50

|

25

|

2.5

|

|

50 x 25 x 2.5

|

2.7

|

50

|

25

|

2.5

|

|

50 x 25 x 3

|

3.2

|

50

|

25

|

3

|

|

50 x 30 x 2.5

|

2.9

|

50

|

30

|

2.5

|

|

50 x 30 x 3

|

3.4

|

50

|

30

|

3

|

|

50 x 30 x 3.2

|

3.6

|

50

|

30

|

3.2

|

|

50 x 30 x 3.6

|

4.0

|

50

|

30

|

3.6

|

|

50 x 30 x 4

|

4.4

|

50

|

30

|

4

|

|

50 x 30 x 5

|

5.3

|

50

|

30

|

5

|

|

60 x 40 x 2.5

|

3.7

|

60

|

40

|

2.5

|

|

60 x 40 x 3

|

4.4

|

60

|

40

|

3

|

|

60 x 40 x 3.2

|

4.6

|

60

|

40

|

3.2

|

|

60 x 40 x 3.6

|

5.1

|

60

|

40

|

3.6

|

|

60 x 40 x 4

|

5.6

|

60

|

40

|

4

|

|

60 x 40 x 5

|

6.9

|

60

|

40

|

5

|

|

60 x 40 x 6

|

8.0

|

60

|

40

|

6

|

|

60 x 40 x 6.3

|

8.3

|

60

|

40

|

6.3

|

|

80 x 40 x 3

|

5.3

|

80

|

40

|

3

|

|

80 x 40 x 3.2

|

5.6

|

80

|

40

|

3.2

|

|

80 x 40 x 3.6

|

6.3

|

80

|

40

|

3.6

|

|

80 x 40 x 4

|

6.9

|

80

|

40

|

4

|

|

80 x 40 x 5

|

8.4

|

80

|

40

|

5

|

|

80 x 40 x 6

|

9.9

|

80

|

40

|

6

|

|

80 x 40 x 6.3

|

10.3

|

80

|

40

|

6.3

|

|

80 x 40 x 8

|

12.5

|

80

|

40

|

8

|

|

90 x 50 x 3

|

6.2

|

90

|

50

|

3

|

|

90 x 50 x 3.2

|

6.6

|

90

|

50

|

3.2

|

|

90 x 50 x 3.6

|

7.4

|

90

|

50

|

3.6

|

|

90 x 50 x 4

|

8.2

|

90

|

50

|

4

|

|

90 x 50 x 5

|

10.0

|

90

|

50

|

5

|

|

90 x 50 x 6

|

11.8

|

90

|

50

|

6

|

|

90 x 50 x 6.3

|

12.3

|

90

|

50

|

6.3

|

|

90 x 50 x 8

|

15.0

|

90

|

50

|

8

|

|

100 x 50 x 3

|

6.7

|

100

|

50

|

3

|

|

100 x 50 x 3.2

|

7.1

|

100

|

50

|

3.2

|

|

100 x 50 x 3.6

|

8.0

|

100

|

50

|

3.6

|

|

100 x 50 x 4

|

8.8

|

100

|

50

|

4

|

|

100 x 50 x 5

|

10.8

|

100

|

50

|

5

|

|

100 x 50 x 6

|

12.7

|

100

|

50

|

6

|

|

100 x 50 x 6.3

|

13.3

|

100

|

50

|

6.3

|

|

100 x 50 x 8

|

16.3

|

100

|

50

|

8

|

|

100 x 60 x 3

|

7.2

|

100

|

60

|

3

|

|

100 x 60 x 3.2

|

7.6

|

100

|

60

|

3.2

|

|

100 x 60 x 3.6

|

8.5

|

100

|

60

|

3.6

|

|

100 x 60 x 4

|

9.4

|

100

|

60

|

4

|

|

100 x 60 x 5

|

11.6

|

100

|

60

|

5

|

|

100 x 60 x 6

|

13.6

|

100

|

60

|

6

|

|

100 x 60 x 6.3

|

14.2

|

100

|

60

|

6.3

|

|

100 x 60 x 8

|

17.5

|

100

|

60

|

8

|

|

120 x 60 x 3.6

|

9.7

|

120

|

60

|

3.6

|

|

120 x 60 x 4

|

10.7

|

120

|

60

|

4

|

|

120 x 60 x 5

|

13.1

|

120

|

60

|

5

|

|

120 x 60 x 6

|

15.5

|

120

|

60

|

6

|

|

120 x 60 x 6.3

|

16.2

|

120

|

60

|

6.3

|

|

120 x 60 x 8

|

20.1

|

120

|

60

|

8

|

|

120 x 60 x 10

|

24.6

|

120

|

60

|

10

|

|

120 x 80 x 3.6

|

10.8

|

120

|

80

|

3.6

|

|

120 x 80 x 4

|

11.9

|

120

|

80

|

4

|

|

120 x 80 x 5

|

14.7

|

120

|

80

|

5

|

|

120 x 80 x 6

|

17.4

|

120

|

80

|

6

|

|

120 x 80 x 6.3

|

18.2

|

120

|

80

|

6.3

|

|

120 x 80 x 8

|

22.6

|

120

|

80

|

8

|

|

120 x 80 x 10

|

27.4

|

120

|

80

|

10

|

|

140 x 80 x 4

|

13.2

|

140

|

80

|

4

|

|

140 x 80 x 5

|

16.3

|

140

|

80

|

5

|

|

140 x 80 x 6

|

19.3

|

140

|

80

|

6

|

|

140 x 80 x 6.3

|

20.2

|

140

|

80

|

6.3

|

|

140 x 80 x 8

|

25.1

|

140

|

80

|

8

|

|

140 x 80 x 10

|

30.6

|

140

|

80

|

10

|

|

150 x 100 x 4

|

15.1

|

150

|

100

|

4

|

|

150 x 100 x 5

|

18.6

|

150

|

100

|

5

|

|

150 x 100 x 6

|

22.1

|

150

|

100

|

6

|

|

150 x 100 x 6.3

|

23.1

|

150

|

100

|

6.3

|

|

150 x 100 x 8

|

28.9

|

150

|

100

|

8

|

|

150 x 100 x 10

|

35.3

|

150

|

100

|

10

|

|

150 x 100 x 12

|

41.4

|

150

|

100

|

12

|

|

150 x 100 x 12.5

|

42.8

|

150

|

100

|

12.5

|

|

160 x 80 x 4

|

14.4

|

160

|

80

|

4

|

|

160 x 80 x 5

|

17.8

|

160

|

80

|

5

|

|

160 x 80 x 6

|

21.2

|

160

|

80

|

6

|

|

160 x 80 x 6.3

|

22.2

|

160

|

80

|

6.3

|

|

160 x 80 x 8

|

27.6

|

160

|

80

|

8

|

|

160 x 80 x 10

|

33.7

|

160

|

80

|

10

|

|

160 x 80 x 12

|

39.5

|

160

|

80

|

12

|

|

160 x 80 x 12.5

|

40.9

|

|160

|

80

|

12.5

|

|

180 x 100 x 4

|

16.9

|

180

|

100

|

4

|

|

180 x 100 x 5

|

21.0

|

180

|

100

|

5

|

|

180 x 100 x 6

|

24.9

|

180

|

100

|

6

|

|

180 x 100 x 6.3

|

26.1

|

180

|

100

|

6.3

|

|

180 x 100 x 8

|

32.6

|

180

|

100

|

8

|

|

180 x 100 x 10

|

40.0

|

180

|

100

|

10

|

|

180 x 100 x 12

|

47.0

|

180

|

100

|

12

|

|

180 x 100 x 12.5

|

48.7

|

180

|

100

|

12.5

|

|

200 x 100 x 4

|

18.1

|

200

|

100

|

4

|

|

200 x 100 x 5

|

22.6

|

200

|

100

|

5

|

|

200 x 100 x 6

|

26.8

|

200

|

100

|

6

|

|

200 x 100 x 6.3

|

28.1

|

200

|

100

|

6.3

|

|

200 x 100 x 8

|

35.1

|

200

|

100

|

8

|

|

200 x 100 x 10

|

43.1

|

200

|

100

|

10

|

|

200 x 100 x 12

|

50.8

|

200

|

100

|

12

|

|

200 x 100 x 12.5

|

52.7

|

200

|

100

|

12.5

|

|

200 x 100 x 16

|

65.2

|

200

|

100

|

16

|

|

200 x 120 x 6

|

28.7

|

200

|

120

|

6

|

|

200 x 120 x 6.3

|

29.9

|

200

|

120

|

6.3

|

|

200 x 120 x 8

|

37.3

|

200

|

120

|

8

|

|

200 x 120 x 10

|

45.9

|

200

|

120

|

10

|

|

200 x 120 x 12

|

54.5

|

200

|

120

|

12

|

|

200 x 120 x 12.5

|

55.7

|

200

|

120

|

12.5

|

|

250 x 150 x 5

|

30.4

|

250

|

150

|

5

|

|

250 x 150 x 6

|

36.2

|

250

|

150

|

6

|

|

250 x 150 x 6.3

|

38.0

|

|250

|

150

|

6.3

|

|

250 x 150 x 8

|

47.7

|

250

|

150

|

8

|

|

250 x 150 x 10

|

58.8

|

250

|

150

|

10

|

|

250 x 150 x 12

|

69.6

|

250

|

150

|

12

|

|

250 x 150 x 12.5

|

72.3

|

250

|

150

|

12.5

|

|

250 x 150 x 16

|

90.3

|

250

|

150

|

16

|

|

260 x 180 x 6

|

40.0

|

260

|

180

|

6

|

|

260 x 180 x 6.3

|

41.9

|

260

|

180

|

6.3

|

|

260 x 180 x 8

|

52.7

|

260

|

180

|

8

|

|

260 x 180 x 10

|

65.1

|

260

|

180

|

10

|

|

260 x 180 x 12

|

77.2

|

260

|

180

|

12

|

|

260 x 180 x 12.5

|

80.1

|

260

|

180

|

12.5

|

|

260 x 180 x 16

|

100.0

|

260

|

180

|

16

|

|

300 x 200 x 5

|

38.3

|

300

|

200

|

5

|

|

300 x 200 x 6

|

45.7

|

300

|

200

|

6

|

|

300 x 200 x 6.3

|

47.9

|

300

|

200

|

6.3

|

|

300 x 200 x 8

|

60.3

|

300

|

200

|

8

|

|

300 x 200 x 10

|

74.5

|

300

|

200

|

10

|

|

300 x 200 x 12

|

88.5

|

300

|

200

|

12

|

|

300 x 200 x 12.5

|

91.9

|

300

|

200

|

12.5

|

|

300 x 200 x 16

|

115.0

|

300

|

200

|

16

|

|

350 x 250 x 6

|

55.1

|

350

|

250

|

6

|

|

350 x 250 x 6.3

|

57.8

|

350

|

250

|

6.3

|

|

350 x 250 x 8

|

72.8

|

350

|

250

|

8

|

|

350 x 250 x 10

|

90.2

|

350

|

250

|

10

|

|

350 x 250 x 12

|

107.0

|

|350

|

250

|

12

|

|

350 x 250 x 12.5

|

112.0

|

350

|

250

|

12.5

|

|

350 x 250 x 16

|

141.0

|

350

|

250

|

16

|

|

400 x 200 x 6

|

55.1

|

400

|

200

|

6

|

|

400 x 200 x 6.3

|

57.8

|

400

|

200

|

6.3

|

|

400 x 200 x 8

|

72.8

|

400

|

200

|

8

|

|

400 x 200 x 10

|

90.2

|

400

|

200

|

10

|

|

400 x 200 x 12

|

107.0

|

400

|

200

|

12

|

|

400 x 200 x 12.5

|

112.0

|

400

|

200

|

12.5

|

|

400 x 200 x 16

|

141.0

|

400

|

200

|

16

|

|

450 x 250 x 8

|

85.4

|

450

|

250

|

8

|

|

450 x 250 x 10

|

106.0

|

450

|

250

|

10

|

|

450 x 250 x 12

|

126.0

|

450

|

250

|

12

|

|

450 x 250 x 12.5

|

131.0

|

450

|

250

|

12.5

|

|

450 x 250 x 16

|

166.0

|

450

|

250

|

16

|

|

500 x 300 x 8

|

97.9

|

500

|

300

|

8

|

|

500 x 300 x 10

|

122.0

|

500

|

300

|

10

|

|

500 x 300 x 12

|

145.0

|

500

|

300

|

12

|

|

500 x 300 x 12.5

|

151.0

|

500

|

300

|

12.5

|

|

500 x 300 x 16

|

191.0

|

500

|

300

|

16

|

|

500 x 300 x 20

|

235.0

|

500

|

300

|

20

|

Rectangular tube processing technology

Rectangular tube is a common metal tube with a square or rectangular cross-sectional shape. In industrial production, rectangular tubes are widely used in construction, machinery manufacturing, automobile manufacturing and other fields. The processing technology of rectangular tubes has an important impact on the quality and performance of the product.

The processing technology of rectangular tubes includes blanking, edge making, forming, welding, straightening, trimming, hair removal, rust prevention and other links. The first step is to cut the raw material steel plate or steel coil according to the required size to obtain a rectangular tube of the required length. During the edge making process, the edges of the rectangular tube are processed through cutting, grooving, edge grinding and other processes to ensure the flatness and dimensional accuracy of the edge.

The processing technology of rectangular tubes is crucial to the quality and performance of the product. Only through scientific and reasonable processing technology can we produce rectangular tube products with excellent quality and precise dimensions. At the same time, attention should be paid to protecting the surface of the rectangular tube during processing to prevent damage and corrosion.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.