General series: 0.30mm、0.35mm、0.50mm、0.65mm

Motor Company general requirements

High efficient series: 0.35mm、0.50mm

High efficient motor, high efficient compressor motor, frequency conversion motor etc.

Stress relief annealing series: 0.35mm、0.50mm

high speed stamping products, EI transformer, air conditioner motor etc.

New energy vehicle series: 0.20mm、0.25mm、0.27mm、0.30mm

automobile motor, transformer, reactor etc

Classification of electrical steel

|

|

Category

|

Silicon content, %

|

Nominal thickness, mm

|

|

|

Hot rolled silicon steel plate

(no orientation)

|

Hot-rolled low-silicon steel (hot-rolled electrical steel)

|

1.0~2.5

|

0.50

|

|

|

Hot-rolled high-silicon steel (hot-rolled transformer steel)

|

3.0~4.5

|

0.35 and 0.50

|

|

|

|

Cold rolled electrical steel sheet

|

Non-oriented electrical steel

(cold-rolled electrical steel)

|

Low carbon electrical steel

|

≤0.5

|

0.50 and 0.65

|

|

Silicon steel

|

>0.5~3.2

|

0.35 and 0.50

|

|

|

|

Oriented silicon steel

(cold-rolled transformer steel)

|

Ordinary grain oriented silicon steel

|

2.9~3.3

|

0.20,0.23,0.27

0.30 and 0.35

|

|

|

|

High magnetic induction oriented silicon steel

|

2.9~3.3

|

|

|

In addition to the types of electrical steel in the above table, there are also some electrical steel sheets for special purposes, such as 0.15 and 0.20mm thick 3%Si cold-rolled non-oriented silicon steel strips and 0.025, 0.05 and 0.1mm thick 3%Si cold-rolled oriented silicon steel thin strips. 0.7mm thick 3% Si high-strength cold-rolled non-oriented silicon steel plate for relays and power switches; high-strength cold-rolled electrical steel plate for new high-speed motor rotors ; Low-carbon electrical steel hot-rolled thick plates and cold-rolled plates for magnetic shielding of medical nuclear magnetic resonance tomography scanners and high-energy accelerator electromagnets; 4.5%~6.5% Si high-silicon steel plates for high-frequency motors and transformers, and magnetic shielding, etc. .

Properties of electrical Steel

General series

Grade

|

Nominal

Thickness

(mm)

|

Theoretical density

(kg/dm3)

|

Theoretical density

(kg/dm3)

|

Min.Magnetic induction(T)

|

50Hz

|

|

B25

|

B50

|

B100

|

|

30SW230

|

0.3

|

7.65

|

2.30

|

2.90

|

1.49

|

1.60

|

1.70

|

|

35SW230

|

0.35

|

7.60

|

2.30

|

2.90

|

1.49

|

1.62

|

1.70

|

|

35SW250

|

0.35

|

7.65

|

2.50

|

3.14

|

1.49

|

1.62

|

1.70

|

|

35SW270

|

0.35

|

7.65

|

2.70

|

3.36

|

1.49

|

1.62

|

1.70

|

|

35SW300

|

0.35

|

7.65

|

3.00

|

3.74

|

1.49

|

1.62

|

1.70

|

|

35SW330

|

0.35

|

7.65

|

3.30

|

4.12

|

1.50

|

1.62

|

1.71

|

|

35SW360

|

0.35

|

7.65

|

3.60

|

4.55

|

1.51

|

1.63

|

1.72

|

|

35SW400

|

0.35

|

7.65

|

4.00

|

5.10

|

1.53

|

1.64

|

1.74

|

|

35SW440

|

0.35

|

7.70

|

4.40

|

5.60

|

1.54

|

1.65

|

1.74

|

|

50SW230

|

0.50

|

7.60

|

2.30

|

3.00

|

1.49

|

1.62

|

1.70

|

|

50SW250

|

0.50

|

7.60

|

2.50

|

3.21

|

1.49

|

1.62

|

1.70

|

|

50SW270

|

0.50

|

7.65

|

2.70

|

3.47

|

1.49

|

1.62

|

1.70

|

|

50SW290

|

0.50

|

7.65

|

2.90

|

3.71

|

1.49

|

1.62

|

1.70

|

|

50SW310

|

0.50

|

7.65

|

3.10

|

3.95

|

1.49

|

1.62

|

1.70

|

|

50SW330

|

0.50

|

7.65

|

3.30

|

4.20

|

1.49

|

1.60

|

1.70

|

|

50SW350

|

0.50

|

7.65

|

3.50

|

4.45

|

1.50

|

1.62

|

1.70

|

|

50SW400

|

7.70

|

4.00

|

5.10

|

1.53

|

1.64

|

1.73

|

|

50SW470

|

0.50

|

7.70

|

4.70

|

5.90

|

1.54

|

1.65

|

1.74

|

|

50SW530

|

0.50

|

7.70

|

5.30

|

6.66

|

1.56

|

1.65

|

1.75

|

|

50SW600

|

0.50

|

7.75

|

6.00

|

7.55

|

1.57

|

1.67

|

1.76

|

|

50SW700

|

0.50

|

7.80

|

7.00

|

8.80

|

1.60

|

1.69

|

1.77

|

|

50SW800

|

0.50

|

7.80

|

8.00

|

10.10

|

1.60

|

1.70

|

1.78

|

|

50SW1000

|

0.50

|

7.85

|

10.00

|

12.60

|

1.62

|

1.73

|

1.81

|

|

50SW1300

|

0.50

|

7.85

|

13.00

|

16.40

|

1.62

|

1.74

|

1.81

|

|

65SW400

|

0.65

|

7.65

|

4.00

|

5.20

|

1.52

|

1.65

|

1.72

|

|

65SW600

|

0.65

|

7.75

|

6.00

|

7.71

|

1.56

|

1.68

|

1.76

|

|

65SW700

|

0.65

|

7.75

|

7.00

|

8.89

|

1.57

|

1.67

|

1.76

|

|

65SW800

|

7.80

|

8.00

|

10.26

|

1.60

|

1.70

|

1.78

|

|

0.65

|

|

65SW1000

|

0.65

|

7.80

|

10.00

|

12.77

|

1.61

|

1.71

|

1.80

|

|

65SW1300

|

0.65

|

7.85

|

13.00

|

16.60

|

1.61

|

1.71

|

1.80

|

High Efficient Series

|

Grade

|

Nominal Thickness

|

Nominal Density

|

P15/50

Max. loss

|

B50

|

|

Min. Magnetic induction

|

|

Grade

|

(mm)

|

(kg/dm3)

|

(W/kg)

|

(T)

|

|

35SWH250

|

0.35

|

7.65

|

2.50

|

1.68

|

|

50SWH470

|

0.50

|

7.70

|

4.70

|

1.72

|

|

50SWG470

|

0.50

|

7.75

|

4.70

|

1.72

|

|

50SWH600

|

0.50

|

7.75

|

6.00

|

1.72

|

|

50SWH800

|

0.50

|

7.80

|

8.00

|

1.74

|

|

50SWH1300

|

0.50

|

7.85

|

13.0

|

1.76

|

Stress Reliefannealing Series

Grade

|

Nominal Thickness

|

Nominal Density

|

P15/50

|

B50

|

Max. loss

|

Min. Magnetic induction

|

(mm)

|

(kg/dm3)

|

(W/kg)

|

(T)

|

|

35SWR300

|

0.35

|

7.80

|

3.00

|

1.73

|

|

50SWR350

|

0.50

|

7.80

|

3.50

|

1.74

|

|

50SWR450

|

0.50

|

7.85

|

4.50

|

1.72

|

New Energy Vehicle Series

Grade

|

Normal

|

Nominal Density

|

P10/400

|

B50

|

Thickness

|

Max. core loss

|

Min. Magnetic induction

|

|

(mm)

|

(kg/dm3)

|

(W/kg)

|

(T)

|

|

20SW1200

|

0.20

|

7.60

|

12.0

|

1.61

|

|

20SW1500

|

0.20

|

7.65

|

13.0

|

1.64

|

|

25SW1250

|

0.25

|

7.60

|

12.5

|

1.63

|

|

25SW1250H

|

0.25

|

7.60

|

12.5

|

1.65

|

|

25SW1300

|

0.25

|

7.60

|

13.0

|

1.63

|

|

27SW1400H

|

0.27

|

7.60

|

14.0

|

1.65

|

|

27SW1400

|

0.27

|

7.60

|

14.0

|

1.64

|

|

27SWH1400

|

0.27

|

7.65

|

14.0

|

1.64

|

|

27SWG1400

|

0.27

|

7.65

|

14.0

|

1.67

|

|

30SW1500

|

0.30

|

7.60

|

15.0

|

1.64

|

|

30SWH1500

|

0.30

|

7.65

|

15.0

|

1.65

|

|

30SWG1500

|

0.30

|

7.65

|

15.0

|

1.67

|

|

35SW1700

|

0.35

|

7.60

|

17.0

|

1.64

|

|

35SWG1700

|

0.35

|

7.65

|

17.0

|

1.68

|

|

35SW1700H

|

0.35

|

7.60

|

17.0

|

1.63

|

|

35SW1900

|

0.35

|

7.65

|

19.0

|

1.66

|

|

35SWH1900

|

0.35

|

7.65

|

19.0

|

1.67

|

Production process of electrical steel

|

smelt

|

|

Silicon steel is mainly smelted by oxygen converter, combined with vacuum treatment of molten steel and AOD technology during smelting and aluminum (0.2-0.5%) content to meet the requirements of different magnetic properties. The silicon and aluminum content of high-grade silicon steel sheets should be increased accordingly. Carbon, sulfur and inclusions should be minimized.

|

|

rolling

|

|

The magnetism, surface quality, filling factor and punchability of cold-rolled silicon steel sheets are better than those of hot-rolled silicon steel sheets, and they can be produced in coils. Therefore, some countries have stopped producing hot-rolled silicon steel sheets since the 1960s. China adopts a low temperature of about 900 ℃ one-time rapid hot rolling and stacking annealing under the protection of hydrogen to manufacture hot-rolled silicon steel sheets. The yield is high, and the surface quality and magnetic properties of the finished products are good.

|

|

pickling

|

|

The oxides of the hot-rolled steel strip are removed by the descaling machine and the hydrochloric acid tank to prevent surface defects of the cold-rolled finished product.

|

|

cold rolling

|

|

In order to ensure the thickness and material for different purposes, the deceleration ratio is set at 40%-90%, and advanced control equipment such as automatic thickness control and automatic shape control is realized.

|

|

annealing

|

|

It is a process of softening the material of the steel strip hardened in the cold stamping process. Through metal heating and rapid cooling, steel for deep processing and high-tensile steel are produced, and boxing (cover annealing) annealing and continuous annealing methods are adopted.

|

|

insulating coating

|

|

When the silicon steel plate is processed into an iron core, in order to improve its processing performance and prevent eddy current loss equivalent to the multiplication of the thickness of the steel plate, continuous coating equipment is used to spray insulating coating liquid on the upper and lower sides of the steel plate.

|

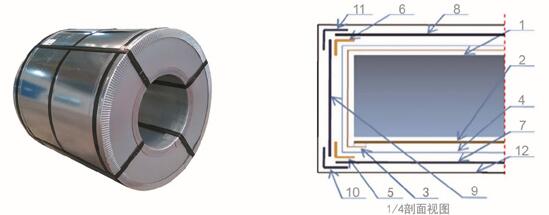

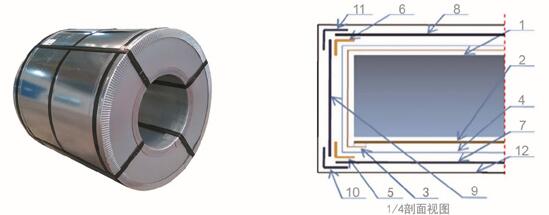

Product Packing

|

|

|

1.Rolled silicon steel

|

7.Inner iron plate guard

|

|

2.Inner rusty-resisted paper

|

8.Outside iron plate guard

|

|

3.Outside anti-rust paper

|

9.End iron plate guard

|

|

4.Plastic seal

|

10.Inner iron corner guard

|

|

5. Inner paper corner guard

|

11.Outside iron corner guard

|

|

6.Outside paper corner guard

|

12.Radial iron banding strip

|

-Product grade standard

|

Type

|

(mm)

|

Shougang

|

NSC

|

JFE

|

TKS

|

Posco

|

NI&Sco

|

AK

|

|

Thickness

|

|

General series

|

0.35

|

35SW230

|

35H230

|

35JN230

|

M235-35A

|

35PN230

|

|

|

|

35SW250

|

35H250

|

35JN250

|

M250-35A

|

35PN250

|

2413

|

M-15

|

|

35SW270

|

35H270

|

35JN270

|

M270-35A

|

35PN270

|

2412

|

M-19

|

|

35SW300

|

35H300

|

35JN300

|

M300-35A

|

35PN300

|

2411

|

M-22/M-27

|

|

35SW360

|

35H360

|

35JN360

|

|

35PN360

|

|

|

|

35SW440

|

35H440

|

35JN440

|

|

35PN455

|

|

|

|

35SW550

|

|

|

|

35PN560

|

|

|

|

0.50

|

50SW230

|

50H230

|

50JN230

|

M230-50A

|

50PN230

|

|

|

|

50SW250

|

50H250

|

50JN250

|

M250-50A

|

50PN250

|

|

|

|

50SW270

|

50H270

|

50JN270

|

M270-50A

|

50PN270

|

2414

|

|

|

50SW290

|

50H290

|

50JN290

|

M290-50A

|

50PN290

|

2413

|

M-15

|

|

50SW310

|

50H310

|

50JN310

|

M310-50A

|

50PN310

|

2412

|

M-19

|

|

|

|

|

|

|

|

|

|

0.50

|

50H350

|

50JN350

|

M350-50A

|

50PN350

|

|

M-22

|

|

|

|

M400-65A

|

50PN400

|

|

M-27/M-36

|

|

50SW470

|

50H470

|

50JN470

|

M470-50A

|

50PN445

|

2214

|

|

|

50SW600

|

50H600

|

50JN600

|

M600-50A

|

50PN595

|

2212

|

|

|

50SW700

|

50H700

|

50JN700

|

M700-50A

|

50PN760

|

|

M-47

|

|

50SW800

|

50H800

|

50JN800

|

M800-50A

|

50PN890

|

2011

|

|

|

50SW1000

|

50H1000

|

50JN1000

|

M940-50A

|

50PN1015

|

|

|

|

50SW1300

|

50H1300

|

50JN1300

|

M1100-50A

|

50PN1270

|

|

|

|

0.65

|

65SW400

|

|

|

|

65PN400

|

|

|

|

65SW800

|

|

65JN800

|

M800-65A

|

65PN890

|

|

M-47

|

|

65SW1000

|

|

65JN1000

|

M1000-65A

|

65PN1015

|

|

|

|

65SW1300

|

|

65JN1300

|

M1300-65A

|

65PN1270

|

|

|

|

High efficient series

|

0.35

|

35SWH250

|

|

|

|

|

|

|

|

35SWH300

|

|

|

|

|

|

|

|

0.50

|

50SWH470

|

|

50JNE470

|

|

|

|

|

|

50SWH600

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50SWH1300

|

|

|

|

|

|

|

Stress relief

annealing series

|

0.50

|

50SWR350

|

|

50JNA350

|

|

|

|

|

50SWR1300

|

|

|

|

|

|

|

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.