Square Tube is a common metal pipe with a square or rectangular cross-sectional shape. In industrial production, square tubes are widely used in construction, machinery manufacturing, automobile manufacturing and other fields. The processing technology of square tubes has an important impact on the quality and performance of the product.

Square Tube are often used for columns, Square Tubes are often called “box sections”. An example is 100 x 100 x 10 SHS, which is 100 mm deep, 100 mm wide and the wall is 10 mm thick. Similar to Rectangular Tubes, hot rolled Square Tubes are made at the mill as one piece, whereas cold formed SHS are made of a flat sheet rolled at right angles and welded. It is therefore easy to note the difference, as the cold rolled Square Tubes have a weld all along their length.

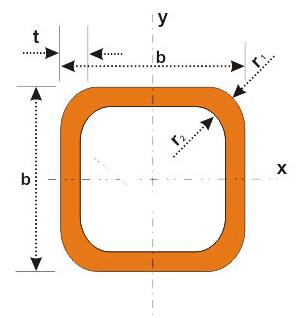

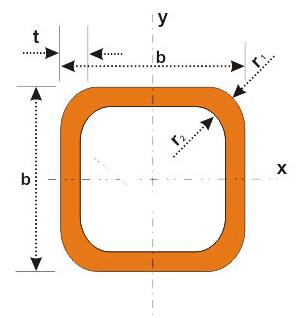

Square tube sizes

|

Type

|

Weight

[kg/m]

|

Height

[mm]

|

Width

[mm]

|

Wall

thickness

[mm]

|

|

20 x 20 x 2

|

1.1

|

20

|

20

|

2

|

|

20 x 20 x 2.5

|

1.3

|

20

|

20

|

2.5

|

|

25 x 25 x 2

|

14

|

25

|

25

|

2

|

|

25 x 25 x 2.5

|

1.7

|

25

|

25

|

2.5

|

|

25 x 25 x 3

|

2.0

|

25

|

25

|

3

|

|

30 x 30 x 2

|

1.7

|

30

|

30

|

2

|

|

30 x 30 x 2.5

|

2.1

|

30

|

30

|

2.5

|

|

30 x 30 x 3

|

2.5

|

30

|

30

|

3

|

|

40 x 40 x 2.5

|

2.9

|

40

|

40

|

2.5

|

|

40 x 40 x 3

|

3.4

|

40

|

40

|

3

|

|

40 x 40 x 3.2

|

3.6

|

40

|

40

|

3.2

|

|

40 x 40 x 3.6

|

4.0

|

40

|

40

|

3.6

|

|

40 x 40 x 4

|

4.4

|

40

|

40

|

4

|

|

40 x 40 x 5

|

5.3

|

40

|

40

|

5

|

|

50 x 50 x 2.5

|

3.7

|

50

|

50

|

2.5

|

|

50 x 50 x 3

|

4.4

|

50

|

50

|

3

|

|

50 x 50 x 3.2

|

4.6

|

50

|

50

|

3.2

|

|

50 x 50 x 3.6

|

5.1

|

50

|

50

|

3.6

|

|

50 x 50 x 4

|

5.6

|

50

|

50

|

4

|

|

50 x 50 x 5

|

6.9

|

50

|

50

|

5

|

|

50 x 50 x 6

|

8.0

|

50

|

50

|

6

|

|

50 x 50 x 6.3

|

8.3

|

50

|

50

|

6.3

|

|

60 x 60 x 2.5

|

4.5

|

60

|

60

|

2.5

|

|

60 x 60 x 3

|

5.3

|

60

|

60

|

3

|

|

60 x 60 x 3.2

|

5.6

|

60

|

60

|

3.2

|

|

60 x 60 x 3.6

|

6.3

|

60

|

60

|

3.6

|

|

60 x 60 x 4

|

6.9

|

60

|

60

|

4

|

|

60 x 60 x 5

|

8.4

|

60

|

60

|

5

|

|

60 x 60 x 6

|

9.9

|

60

|

60

|

6

|

|

60 x 60 x 6.3

|

10.3

|

60

|

60

|

6.3

|

|

60 x 60 x 8

|

12.5

|

60

|

60

|

8

|

|

70 x 70 x 3

|

6.2

|

70

|

70

|

3

|

|

70 x 70 x 3.2

|

6.6

|

70

|

70

|

3.2

|

|

70 x 70 x 3.6

|

7.4

|

70

|

70

|

3.6

|

|

70 x 70 x 4

|

8.2

|

70

|

70

|

4

|

|

70 x 70 x 5

|

10.0

|

70

|

70

|

5

|

|

70 x 70 x 6

|

11.8

|

70

|

70

|

6

|

|

70 x 70 x 6.3

|

12.3

|

70

|

70

|

6.3

|

|

70 x 70 x 8

|

15.0

|

70

|

70

|

8

|

|

80 x 80 x 3

|

7.2

|

80

|

80

|

3

|

|

80 x 80 x 3.2

|

7.6

|

80

|

80

|

3.2

|

|

80 x 80 x 3.6

|

8.5

|

80

|

80

|

3.6

|

|

80 x 80 x 4

|

9.4

|

80

|

80

|

4

|

|

80 x 80 x 5

|

11.6

|

80

|

80

|

5

|

|

80 x 80 x 6

|

13.6

|

80

|

80

|

6

|

|

80 x 80 x 6.3

|

14.2

|

80

|

80

|

6.3

|

|

80 x 80 x 8

|

17.8

|

80

|

80

|

8

|

|

90 x 90 x 5

|

13.1

|

90

|

90

|

5

|

|

90 x 90 x 6

|

15.5

|

90

|

90

|

6

|

|

90 x 90 x 6.3

|

16.2

|

90

|

90

|

6.3

|

|

90 x 90 x 8

|

20.1

|

90

|

90

|

8

|

|

100 x 100 x 3.6

|

10.8

|

100

|

100

|

3.6

|

|

100 x 100 x 4

|

11.9

|

100

|

100

|

4

|

|

100 x 100 x 5

|

14.7

|

100

|

100

|

5

|

|

100 x 100 x 6

|

17.4

|

100

|

100

|

6

|

|

100 x 100 x 6.3

|

18.2

|

100

|

100

|

6.3

|

|

100 x 100 x 8

|

22.6

|

100

|

100

|

8

|

|

100 x 100 x 10

|

27.4

|

100

|

100

|

10

|

|

120 x 120 x 4

|

14.4

|

120

|

120

|

4

|

|

120 x 120 x 5

|

18.0

|

120

|

120

|

5

|

|

120 x 120 x 6

|

21.2

|

120

|

120

|

6

|

|

120 x 120 x 6.3

|

22.2

|

120

|

120

|

6.3

|

|

120 x 120 x 8

|

27.6

|

120

|

120

|

8

|

|

120 x 120 x 10

|

33.7

|

120

|

120

|

10

|

|

120 x 120 x 12

|

39.5

|

120

|

120

|

12

|

|

120 x 120 x 12.5

|

40.9

|

120

|

120

|

12.5

|

|

140 x 140 x 5

|

21.0

|

140

|

140

|

5

|

|

140 x 140 x 6

|

24.9

|

140

|

140

|

6

|

|

140 x 140 x 6.3

|

26.1

|

140

|

140

|

6.3

|

|

140 x 140 x 8

|

32.6

|

140

|

140

|

8

|

|

140 x 140 x 10

|

40.0

|

140

|

140

|

10

|

|

140 x 140 x 12

|

47.0

|

140

|

140

|

12

|

|

140 x 140 x 12.5

|

48.7

|

140

|

140

|

12.5

|

|

150 x 150 x 5

|

22.6

|

150

|

150

|

5

|

|

150 x 150 x 6

|

26.8

|

150

|

150

|

6

|

|

150 x 150 x 6.3

|

28.1

|

150

|

150

|

6.3

|

|

150 x 150 x 8

|

35.1

|

150

|

150

|

8

|

|

150 x 150 x 10

|

43.1

|

150

|

150

|

10

|

|

150 x 150 x 12

|

50.8

|

150

|

150

|

12

|

|

150 x 150 x 12.5

|

52.7

|

150

|

150

|

12.5

|

|

150 x 150 x 16

|

65.2

|

150

|

150

|

16

|

|

160 x 160 x 5

|

24.1

|

160

|

160

|

5

|

|

160 x 160 x 6

|

28.7

|

160

|

160

|

6

|

|

160 x 160 x 6.3

|

30.1

|

160

|

160

|

6.3

|

|

160 x 160 x 8

|

37.6

|

160

|

160

|

8

|

|

160 x 160 x 10

|

46.3

|

160

|

160

|

10

|

|

160 x 160 x 12

|

54.6

|

160

|

160

|

12

|

|

160 x 160 x 12.5

|

56.6

|

160

|

160

|

12.5

|

|

160 x 160 x 16

|

70.2

|

160

|

160

|

16

|

|

180 x 180 x 5

|

27.3

|

180

|

180

|

5

|

|

180 x 180 x 6

|

32.5

|

180

|

180

|

6

|

|

180 x 180 x 6.3

|

34.0

|

180

|

180

|

6.3

|

|

180 x 180 x 8

|

42.7

|

180

|

180

|

8

|

|

180 x 180 x 10

|

52.5

|

180

|

180

|

10

|

|

180 x 180 x 12

|

62.1

|

180

|

180

|

12

|

|

180 x 180 x 12.5

|

64.4

|

180

|

180

|

12.5

|

|

180 x 180 x 16

|

80.2

|

180

|

180

|

16

|

|

200 x 200 x 5 SHS

|

30.4

|

200

|

200

|

5

|

|

200 x 200 x 6

|

36.2

|

200

|

200

|

6

|

|

200 x 200 x 6.3

|

38.0

|

200

|

200

|

6.3

|

|

200 x 200 x 8

|

47.7

|

200

|

200

|

8

|

|

200 x 200 x 10

|

58.8

|

200

|

200

|

10

|

|

200 x 200 x 12

|

69.6

|

200

|

200

|

12

|

|

200 x 200 x 12.5

|

72.3

|

200

|

200

|

12.5

|

|

200 x 200 x 16

|

90.3

|

200

|

200

|

16

|

|

220 x 220 x 6

|

40.0

|

220

|

220

|

6

|

|

220 x 220 x 6.3

|

41.9

|

220

|

220

|

6.3

|

|

220 x 220 x 8

|

52.7

|

220

|

220

|

8

|

|

220 x 220 x 10

|

65.1

|

220

|

220

|

10

|

|

220 x 220 x 12

|

77.2

|

220

|

220

|

12

|

|

220 x 220 x 12.5

|

80.1

|

220

|

220

|

12.5

|

|

220 x 220 x 16

|

100.0

|

220

|

220

|

16

|

|

250 x 250 x 5

|

38.3

|

250

|

250

|

5

|

|

250 x 250 x 6

|

45.7

|

250

|

250

|

6

|

|

250 x 250 x 6.3

|

47.9

|

250

|

250

|

6.3

|

|

250 x 250 x 8

|

60.3

|

250

|

250

|

8

|

|

250 x 250 x 10

|

74.5

|

250

|

250

|

10

|

|

250 x 250 x 12

|

88.5

|

250

|

250

|

12

|

|

250 x 250 x 12.5

|

91.9

|

250

|

250

|

12.5

|

|

250 x 250 x 16

|

115.0

|

250

|

250

|

16

|

|

260 x 260 x 6

|

47.6

|

260

|

260

|

6

|

|

260 x 260 x 6.3

|

49.9

|

260

|

260

|

6.3

|

|

260 x 260 x 8

|

62.8

|

260

|

260

|

8

|

|

260 x 260 x 10

|

77.7

|

260

|

260

|

10

|

|

260 x 260 x 12

|

92.2

|

260

|

260

|

12

|

|

260 x 260 x 12.5

|

95.8

|

260

|

260

|

12.5

|

|

260 x 260 x 16

|

120.0

|

260

|

260

|

16

|

|

300 x 300 x 6

|

55.1

|

300

|

300

|

6

|

|

300 x 300 x 6.3

|

57.8

|

300

|

300

|

6.3

|

|

300 x 300 x 8

|

72.8

|

300

|

300

|

8

|

|

300 x 300 x 10

|

90.2

|

300

|

300

|

10

|

|

300 x 300 x 12

|

107.0

|

300

|

300

|

12

|

|

300 x 300 x 12.5

|

112.0

|

300

|

300

|

12.5

|

|

300 x 300 x 16

|

141.0

|

300

|

300

|

16

|

|

350 x 350 x 8

|

85.4

|

350

|

350

|

8

|

|

350 x 350 x 10

|

106.0

|

350

|

350

|

10

|

|

350 x 350 x 12

|

126.0

|

350

|

350

|

12

|

|

350 x 350 x 12.5

|

131.0

|

350

|

350

|

12.5

|

|

350 x 350 x 16

|

166.0

|

350

|

350

|

16

|

|

400 x 400 x 8

|

97.9

|

400

|

400

|

8

|

|

400 x 400 x 10

|

122.0

|

400

|

400

|

10

|

|

400 x 400 x 12

|

145.0

|

400

|

400

|

12

|

|

400 x 400 x 12.5

|

151.0

|

400

|

400

|

12.5

|

|

400 x 400 x 16

|

191.0

|

400

|

400

|

16

|

|

400 x 400 x 20

|

235.0

|

400

|

400

|

20

|

Square tube processing technology

The processing technology of square tubes includes blanking, edge making, forming, welding, straightening, trimming, hair removal, rust prevention and other links. The first step is to cut the raw material steel plate or steel coil according to the required size to obtain a square tube of the required length. During the edge making process, the edges of the square tubes are processed through cutting, grooving, edging and other processes to ensure the flatness and dimensional accuracy of the edges.

In addition to the above processing technology, square pipes also need to be rust-proofed to extend their service life. Common anti-rust methods include spraying anti-rust paint, hot-dip galvanizing, chrome plating, etc. Spraying anti-rust paint is to spray a layer of anti-rust paint on the surface of the square pipe to isolate the air and water and prevent the square pipe from rusting. Hot-dip galvanizing is to immerse square pipes in molten zinc liquid to form a layer of zinc to prevent rust. Chrome plating is to coat the surface of the square tube with a layer of chromium to improve the corrosion resistance of the square tube.

During the processing of square tubes, you need to pay attention to the following points. First of all, the processing dimensions and tolerances are strictly controlled to ensure the dimensional accuracy of the square tube. Secondly, pay attention to protecting the surface of the square tube during processing to avoid scratches or damage. Thirdly, the welded joints must be comprehensively inspected to ensure the quality and strength of the welds. Finally, choose the appropriate material and processing technology according to the different uses of the square tube.

The processing technology of square tubes is crucial to the quality and performance of the product. Only through scientific and reasonable processing technology can we produce square tube products with excellent quality and precise dimensions. At the same time, attention should be paid to protecting the surface of the square tube during processing to prevent damage and rust.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.