Pup joint is a pipe of non-standard length used to adjust the length of tubular strings to its exact requirement.

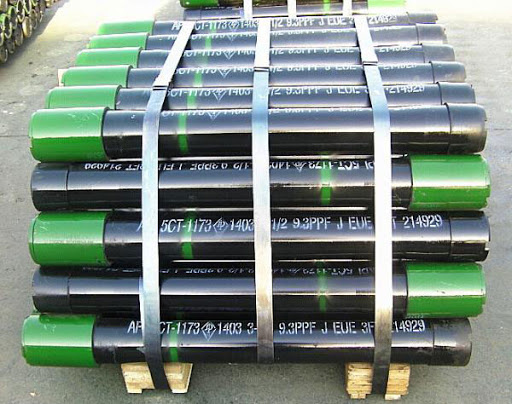

Casing Pup Joints:

Outside Diameter: 4 ½ inch – 13 3/8 inch

Typical Lengths: 1, 2, 3, 4, 6, 8, 10, 12 ft

Grades: H40, J55, K55, N80, L80 T95, C110, P110 Connections: SC, LC, BC, Semi Premium, and Premium

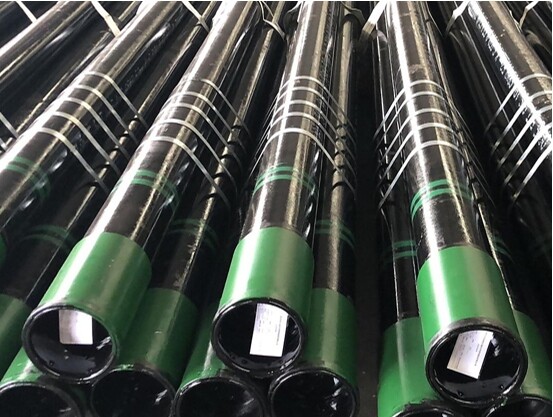

Tubing Pup Joints:

Sizes: 2 ⅜ inch – 4 ½ inch

Typical Lengths: 1, 2, 3, 4, 6, 8, 10, 12 ft

Grades: J-55, N-80, L-80, P-110

Connections EU (external-upset) and NU (non-upset)

Pup Joint Options:

Pin x Pin

Pin x Pin with Couplings Loose

Coupling Box x Pin with Couplings Hand Tight

Coupling Box x Pin with Couplings Bucked-On

Connection Types of Pup joints:

1. API Threaded Pup Joints

The most common pup joint connections conform to API 5CT specifications. API threaded joints use tapered threading that provides high strength and pressure resistance for casing and tubing strings. The tapered thread form consists of symmetric V-shaped wedges that create tight seals under increasing loads. This self-locking characteristic prevents joints from loosening over repeated thermal cycles in harsh downhole environments.

2. EUE Pup Joints

The EUE or external flush threaded connection uses exterior male threads on the pin end that mate with female threads on the box coupling.This design provides a flush outer diameter without recessed threads for unobstructed string installation. EUE threads minimize flow restrictions and turbulence for optimal hydraulic performance.

3. NUE Pup Joints

NUE joints feature female threads machined on the interior walls of the pin end. Corresponding male wedge threads on the coupling provide the sealing force. The smooth outer pin nose facilitates alignment and initial engagement during stabbing.

4. BTC Pup Joints

Buttress threaded connections or BTC represent another common joint variant defined by API 5CT standards. BTC threads utilize angled flanks with substantially increased clamping force and interference compared to API round threads. This provides superior resistance to axial loads and internal pressures.

5. STC Pup Joints

Shoulder threaded connections or STC joints use a multi-stepped thread profile. The design alternates between larger and smaller diameter sections which create axial shoulders. This step profile allows rapid initial mating followed by high torque final tightening to achieve strong sealing and assembly integrity.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.