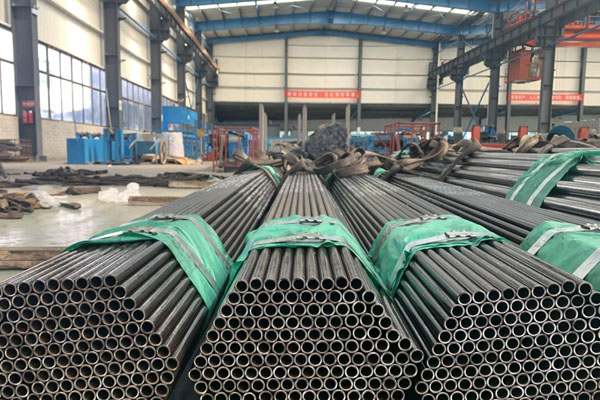

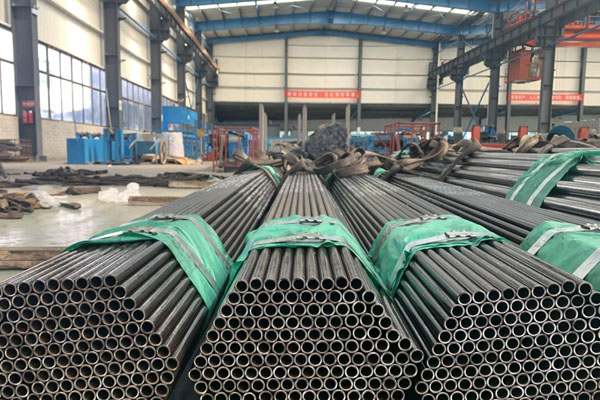

A boiler tube is a type of steel tube. Boiler tubes are generally made of seamless pipes, so boiler tubes are also seamless pipes. However, due to the requirements of the use environment of boiler tubes, the selection of materials is relatively strict, and the steel type is different from seamless pipes.

OUTER DIAMETER (OD) 10.2 - 139.7 mm

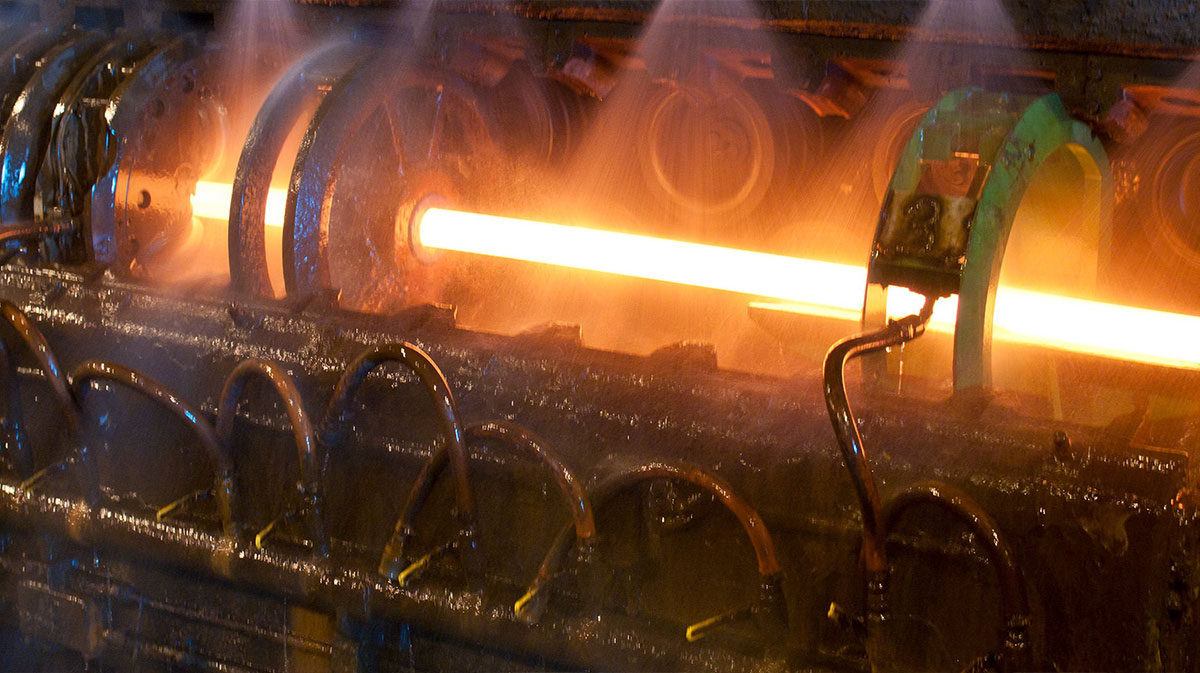

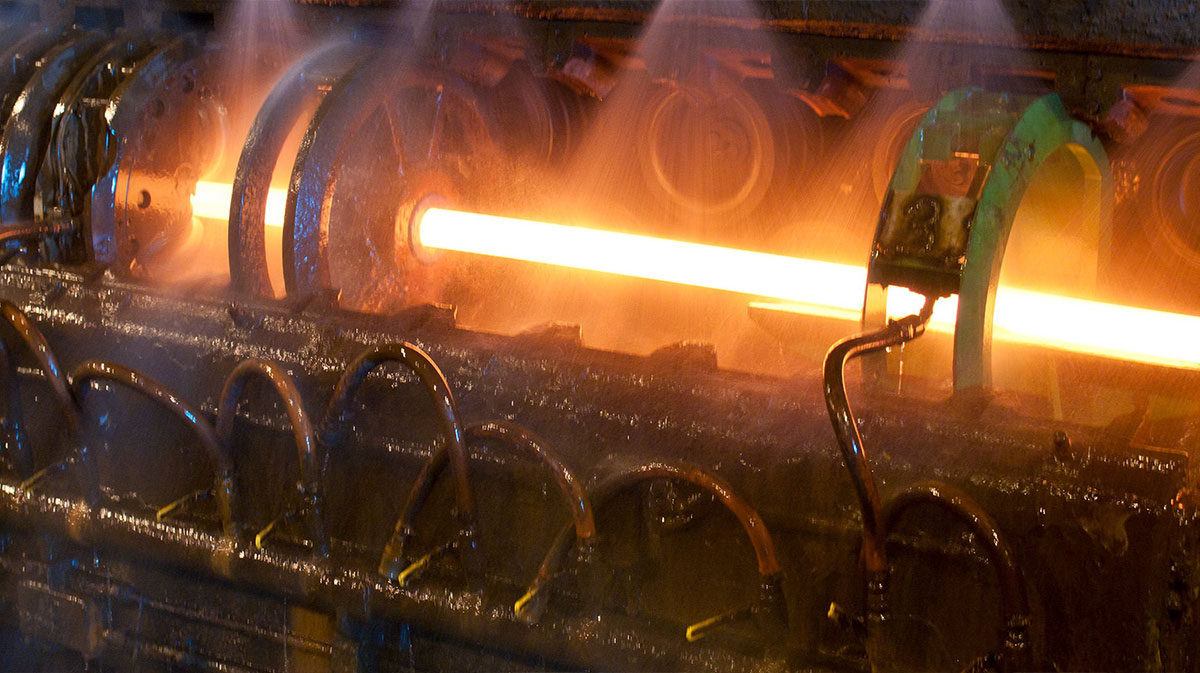

(from 26.9 mm manufactured as hot rolled)

WALL THICKNESS (WT) 0.5 - 16.0 mm

(from 2.6 mm manufactured as hot rolled)

|

ASTM A 210 – A&C

|

Specification for Seamless Medium-Carbon Steel Boiler and Superheater Tubes

|

|

ASTM A 213 - T-5, T-9, T-11, T-22, T-91

|

Specification for Seamless Alloy-Steel Boiler, Superheater and Heat Exchanger Tubes

|

Types of boiler tube standards

1.GB standard

GB standard is a technical standard for boiler tubes formulated by China, mainly including several specific specifications such as GB/T3087, GB/T5310, GB/T6479, etc. Among them, GB/T3087 is applicable to seamless steel pipes for low and medium pressure boilers, GB/T5310 is applicable to high pressure, high temperature and corrosion resistant seamless steel pipes for boilers, and GB/T6479 is applicable to high pressure and high temperature seamless steel pipes for chemical equipment.

GB5310-2017 "Seamless Steel Pipes for High Pressure Boilers"

This standard specifies the relevant technical requirements, inspection methods and allowable deviations for seamless steel pipes for high pressure boilers. This standard applies to seamless steel pipes with a wall thickness of 2.0 to 65 mm and an outer diameter of Φ12.5 to 650 mm, and is used to manufacture pipes and equipment for various high pressure boilers and ultra-high pressure boilers.

GB3087-2018 "Seamless Steel Pipes for Low and Medium Pressure Boilers"

This standard specifies the technical requirements, inspection methods and allowable deviations for seamless steel pipes for low and medium pressure boilers. This standard applies to seamless steel pipes with a wall thickness of 2.0 to 35 mm and an outer diameter of Φ10 to 426 mm, and is used to manufacture pipes and equipment for various low and medium pressure boilers. (3) GB/T 20409-2006 "Technical Delivery Conditions for Seamless Steel Tubes for High-Pressure Boiler Outer Riser"

2. ASTM Standards

ASTM standards strive to allow engineers around the world to use the same terms and symbols, the same measurement system and the same experimental methods, and to ensure the quality of the products. They are one of the most commonly used boiler tube standards in the world. Common ASTM standards include A106, A179, A192, etc.

ASTM A192/A192M

This is the standard specification for seamless carbon steel boiler tubes for high-pressure service, involving minimum wall thickness, and is suitable for seamless carbon steel boilers and superheater tubes for high-pressure service. The standard specifies the specifications, dimensions, chemical composition, mechanical properties, heat treatment, hardness requirements, non-destructive testing and other technical requirements of steel pipes.

ASTM A210/A210M

This standard covers seamless carbon steel pipes for medium and low pressure boilers and superheaters. It is suitable for manufacturing pipes for medium and low pressure boilers and specifies the chemical composition, mechanical properties, dimensions and other requirements of the materials.

3. EN standard

EN standard is a technical standard for boiler pipes formulated in Europe. Similar to ASTM standard, it also unifies the design and selection standards of engineers around the world mainly through terminology, symbols, measurement systems and experimental methods. Common EN standards include EN10216-2, EN10216-3, EN10216-4, etc.

EN10216-2

This is the technical delivery conditions for seamless steel pipes for pressure purposes, especially the requirements for non-alloy steel and alloy steel pipes with high temperature performance. This standard is applicable to boiler pipes for high temperature service.

EN10216-5

This standard specifies the technical delivery conditions for seamless steel pipes for pressure purposes, especially the requirements for stainless steel pipes.

EN10297

This is the standard for seamless steel tubes for mechanical and general engineering purposes. Although it is not specifically for boiler tubes, some of its requirements may be applicable to the production of boiler tubes.

EN 15420

This is the European standard for gas boilers and is related to the safety and performance of boiler tubes.

EN 483

This is the standard for non-destructive testing of welded joints. Although it is not a material standard directly for boiler tubes, boiler tubes need to be non-destructively tested during the manufacturing process to ensure their quality and safety.

Type of boiler tube

There are two significant types of boiler tubes: water-tube tubes and fire-tube tubes.

1.Water-tube boiler tubes

A boiler with a high-pressure water tube has become a boiler in which water flows in tubes externally heated by gases. Within the furnace, fuel is burned, producing hot gas that heats water in the pipes to produce steam. In smaller boiler tubes, the furnace is isolated by external heating tubing. In contrast, larger service boilers depend on the water-filled tubing that makes up the furnace walls to produce steam.

2.Fire-tube boiler tubes

A fire tube boiler is a boiler whereby heated gasses flow from a flame through one or more tubes, flowing through a sealed water tube. The heat of the gasses is transmitted through thermal conduction through the tube walls, heating up the water and eventually producing steam. This boiler was used in the horizontal locomotive configuration on nearly all steam locomotives. This has a tubular container that holds the fire tubes and an extension to fit the one-end firebox. This firebox has an open foundation to have a wide area of the grate, stretching to create a rectangular or tapered structure outside the cylindrical container.

Common materials for boiler tubes

Boiler tubes are usually made of carbon steel, stainless steel, and alloy steel.

1. Carbon steel tube: SA210 C

|

Standard

|

Grade

|

Application

|

|

ASME SA210

|

C

|

ASTM SA210 C pipes are widely used in 300MW, 600MW and other large-capacity power station boilers with operating temperatures below 500℃, such as water-cooled walls, economizers, low-temperature superheaters, etc.

|

2. Alloy steel pipe: SA213 T11, SA213 T12, 15CrMoG, SA213 T22, 12Cr1MoVG, SA213 T23, SA213 T91, SA213 T92.

|

Standard

|

Grade

|

Application

|

|

ASME SA213

|

T11

|

ASME SA213 T11 Boiler, superheater and heat exchanger tubes.

|

|

T12

|

ASME SA213 T12 tubes are widely used in 300MW, 600MW and other large-capacity power station boiler superheaters, reheaters and other heating surface pipes, headers and main steam pipes with working temperature not exceeding 550℃.

|

|

T22

|

ASME SA213 T22 steel pipes are mainly used for 300MW, 600MW and other large-capacity power station boilers with wall temperature ≤580℃ superheaters and wall temperature ≤540℃ steam pipes and headers. This steel grade has been widely used in the United States, Japan, Europe and other countries. It has a long history of operation in power plants and is a mature steel grade with stable operation and good process performance.

|

|

T23

|

SME SA213 T23 seamless steel pipe is mainly suitable for manufacturing superheaters, reheaters and water-cooled walls of large power plant boilers. When the main steam temperature is below 620℃, SA213 T23 seamless steel pipe is a better choice of material.

|

|

T91

|

ASME SA213 T91 steel pipe is mainly used to manufacture high-temperature superheaters, reheaters and other pressure-bearing parts of subcritical and supercritical power plant boilers with metal wall temperatures not exceeding 625℃. It is also used for pressure vessels and nuclear power high-temperature pressure-bearing parts.

|

|

T92

|

ASME SA213 T92 steel pipe has excellent performance and can be used at a temperature of up to 650℃. It can partially replace TP304H and TP347H austenitic stainless steel pipes to manufacture subcritical, supercritical, and even ultra-supercritical power plant boilers with metal wall temperatures not exceeding 650℃, such as high-temperature superheaters, reheater tubes, main steam pipes, etc.

|

|

GB5310

|

15CrMoG

|

GB5310 15CrMoG pipes are suitable for high and medium pressure boiler steam pipes, headers, superheater pipes with a wall temperature of 540℃, forgings and elastic elements with a steam parameter of 510℃.

|

|

12Cr1MoVG

|

GB5310 12Cr1MoVG alloy steel pipes are mainly used for boiler superheaters, reheaters and other heating surface piping systems with a metal wall temperature not exceeding 580℃, boiler headers and main steam pipes and other pressure components with a metal wall temperature not exceeding 565℃.

|

3. Stainless steel pipe: SA213 TP347H, SA213 TP347HFG, SUPER304H, HR3C (SA213 TP310HCbN).

|

Standard

|

Grade

|

Application

|

|

ASME SA213

|

TP347H SA213

|

TP347H stainless steel pipe can be used in high temperature and high pressure environment. The maximum use temperature of the pressure parts is 650℃, and the maximum use temperature of the anti-oxidation parts is 850℃. It is mainly used to make high temperature superheaters, high temperature reheaters, high temperature sections of platen superheaters and various high temperature and high pressure pipe fittings on large power generation boilers with subcritical and supercritical pressure parameters.

|

|

TP347HFG

|

ASME SA213 TP347HFG stainless steel pipe is mainly used to manufacture high temperature superheaters, high temperature reheaters, high temperature sections of platen superheaters and various high temperature and high pressure pipe fittings for large power generation boilers with supercritical pressure parameters.

|

|

Super 304H (S30432)

|

ASME SA213 SUPER304H (S30432) stainless steel pipe is mainly used to manufacture superheaters and reheaters of ultra-supercritical boilers with metal wall temperatures not exceeding 700℃.

|

|

HR3C (SA213 TP310HCbN)

|

HR3C steel has good high temperature corrosion resistance (steam oxidation resistance), and its allowable stress is much higher than that of ordinary SA213 TP310H steel. HR3C (SA213 TP310HCbN) pipes are mainly used for superheaters of ultra-supercritical boilers with harsh working conditions.

|

How to choose the right boiler tube

1. Look at the cross-section of the tube. A good quality seamless tube will have a smooth cross-section and will be devoid of bumps and irregularities.

2. Check the density of the pipe to understand the percentage of impurities in the pipe. If the pipe shows low density, steer clear!

3. Check the surface of the boiler tube. A good quality boiler tube will have a smooth surface. If you find the surface to be rough and uneven, you can be sure that the quality is not up to the mark

Fields of use for Boiler Tubes

Steam Boilers

Fossil Fuel Plants

Heat Exchangers

Electric Power Plants

Cogeneration Facilities

Air Preheater Unit

Waste Heat Plants

Power Generation

Economiser etc

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.