Seamless steel pipe is a continuous metal

steel tube manufactured through hot rolling, cold rolling, or cold drawing.

Solid steel billets are processed into hollow tubes through perforation or

extrusion. No welding is involved in the entire production process, hence the

name "seamless." Compared to welded steel pipe, seamless pipe has

higher structural integrity and pressure-bearing capacity.

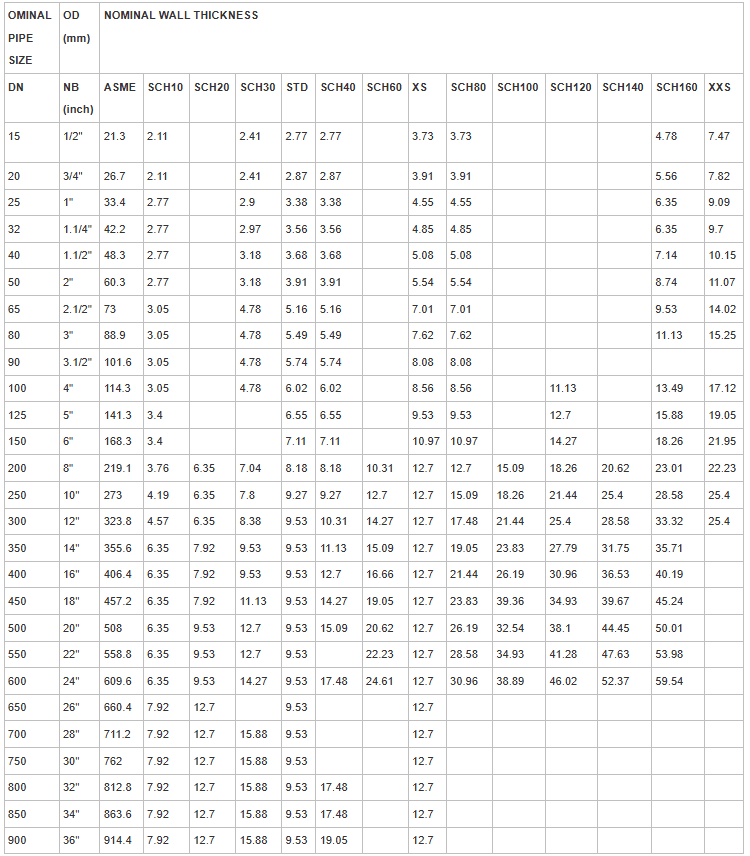

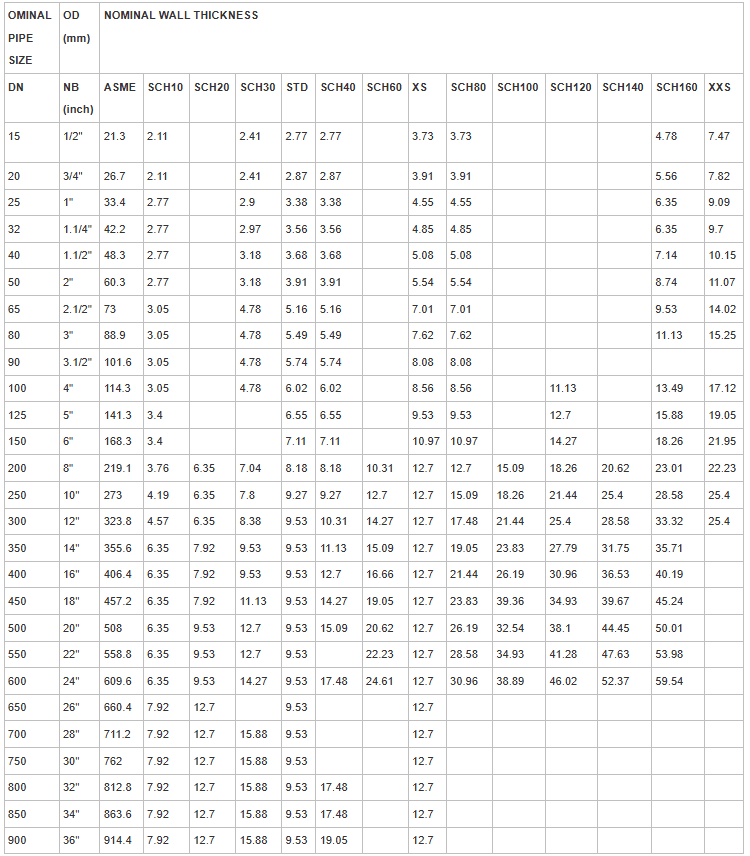

1. Seamless steel pipe outer diameter

1/2 inch - 36 inch (21.3mm-914.4mm)

2. Seamless steel pipe thickness

2.11mm-60mm ( SCH10, SCH20, SCH40, SCH80, STD, SCH120, SCH160, XXS)

Dimensional Parameters of Seamless Steel

Pipe

The dimensions of seamless steel pipe are

primarily determined by three parameters: outer diameter, wall thickness, and

length.

1. Outer Diameter Range

Small Diameter Seamless Steel Pipe: The

outer diameter is typically 6mm to 89mm.

Medium Diameter Seamless Steel Pipe: The

outer diameter is typically 89mm to 219mm.

Large Diameter Seamless Steel Pipe: The

outer diameter is typically 219mm or greater.

2. Wall Thickness Range

Conventional wall thicknesses are

categorized into three types:

SCH5S to SCH160 Standard Wall Thickness

Series

XS/XXS Thickened Series

ST Special Thin Wall Series

Thin-Wall Seamless Steel Pipe: The wall

thickness is typically 1mm to 6mm. Thick-walled seamless steel pipe: Wall

thickness is typically 6mm or thicker, with some reaching 50mm or thicker.

3. Length Specifications

Fixed Lengths: Commonly available in three

standard lengths: 6m, 9m, and 12m.

Multiple Lengths: Specific multiples of

length produced to order.

Special Lengths: Determined based on

production conditions, generally ranging from 4 to 12m.

4. Common Specifications

Small Diameters: Examples include Φ25×2.5, Φ32×3, and Φ57×3.5.

Medium Diameters: Examples include Φ89×4, Φ108×4.5, and Φ159×6.

Large Diameters: Examples include Φ219×8, Φ273×10, and Φ325×12.

Seamless Pipe Size in Different Types

API 5L GR.B, X42,X52,X60,X65 PSL1 & PSL2

Seamless carbon steel pipe size range: 2" - 24"

Seamless carbon steel pipe schedules: STD,SCH100,SCH120,SCH160,XXH

utilized for the water and petroleum industry to transport liquids or as platforms on off-shore rigs.

ASTM A53 GR.B, ASTM A106 GR.B

Seamless carbon steel pipe Size range: 1/8" - 26"

Seamless carbon steel pipe Schedules: SCH20, SCH30, SCH40, STD, SCH100, SCH120,SCH160,XXH

utilized for services ranging from structural supports to steam drum headers with temperature ranges up to 800°F

Seamless boiler tube

outer diameter (OD): 10.2 - 139.7 mm

(from 26.9 mm manufactured as hot rolled)

Seamless boiler tube wall thickness (WT): 0.5 - 16.0 mm

(from 2.6 mm manufactured as hot rolled)

Seamless heat exchanger tube outer diameter

(OD): 6.00 - 101.00 mm

Seamless heat exchanger tube thickness: 0.85 - 12.7mm

Seamless heat exchanger tube length: 1.0 - 27.0 MTR

Seamless precision tube

outer diameter (OD): 10 - 120 mm

Seamless precision tube wall thickness (WT): 0.5 - 5 mm

Seamless precision tube length: 4 - 8m

Seamless hydraulic tube

outer diameter (OD): 4 - 130mm

Seamless hydraulic tube material: E355 (ST52.4),E235 (ST37.4)

Seamless hydraulic tube standard: DIN 2391/C (DIN EN 10305-1),DIN 2445/2 (DIN EN 10305-4)

Seamless hydraulic tube finishing: NBK (Phosphate and Normalized)

Seamless Pipe Size Chart

Factors Affecting Seamless Steel Pipe Sizes

1. Rolling Process Parameters

The piercing

mill's rolling angle and rolling speed directly affect the pipe's outer

diameter accuracy. The reduction and number of rolling passes during cold

rolling determine wall thickness variation. Fluctuations in process parameters

can also lead to dimensional deviations.

2. Raw Material Quality

The diameter,

roundness, and material uniformity of the tube billet are all transferred to

the finished product. If the tube billet exhibits ovality, it can easily result

in an out-of-round outer diameter of the steel pipe.

3. Temperature Control

Excessively high or

uneven heating temperatures can cause inconsistent tube billet deformation, and

differences in cooling rates can cause dimensional shrinkage deviations,

especially in high-precision cold-drawn tubes.

4. Equipment Accuracy

Mechanical

clearances and die wear in equipment such as rolling mills and sizing mills

directly affect the consistency of pipe diameter and wall thickness. Older

equipment can exacerbate dimensional fluctuations.

5. Subsequent Processing

Improper

operation in processes such as straightening and cutting can lead to deviations

in pipe straightness or length.

Dimensional Requirements for Seamless

Steel Pipes in Different Industries

1. Oil and Gas Industry

Large-diameter

(219-1422mm) and thick-walled (6-20mm) seamless steel pipes meet high-pressure,

long-distance transportation requirements and reduce joints.

2. Chemical Industry

Mostly medium-diameter (25-377mm) with a

wall thickness of 5-16mm. Seamless stainless steel pipes are often used for

corrosive media, while small-diameter (10-50mm) pipes can be used for

low-pressure applications.

3. Power Industry

Seamless boiler pipes have an outer

diameter of 32-426mm and a wall thickness of 2.5-20mm. High-pressure boilers

require thicker wall thicknesses, complying with GB5310 standards.

4. Mechanical Manufacturing

Mainly seamless precision pipes with an

outer diameter of 6-200mm and a wall thickness of 0.5-10mm. Dimensional

tolerances are strictly required (within ±0.1mm).

5. Construction Industry

Small-diameter (20-50mm, wall thickness

1-3mm) seamless pipes are used for decoration, while large-diameter (159-630mm,

wall thickness 5-15mm) seamless pipes are used for structural support.

How to Choose Seamless Steel Pipes

1. Clarify Your Usage Requirements

When purchasing seamless steel pipes, first

clarify your usage requirements, including the operating pressure, temperature

range, and other requirements, so you can select the appropriate outer

diameter, wall thickness, and material.

2. Choose a Reputable Brand

When purchasing seamless steel pipes, be

sure to choose products from reputable manufacturers to ensure that their

quality and performance meet standard requirements.

3. Check Product Certificates

When purchasing, review the product's

quality certificate, certificate of conformity, and other relevant documents to

ensure that the product is qualified and complies with national standards.

Read more: ST52 seamless steel pipe or Seamless pipe weight calculation formula

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.