Cold-rolled seamless steel pipes, with

their high dimensional accuracy, excellent surface quality, outstanding

mechanical properties (especially strength), and unique ability to produce

small-diameter, thin-walled tubes, have become the preferred material for

high-end applications with stringent requirements for precision, performance,

and reliability.

This article will provide a detailed

introduction to the production, specifications, materials, standards, and

purchasing guidelines for cold-rolled pipes and cold-rolled seamless steel

pipes.

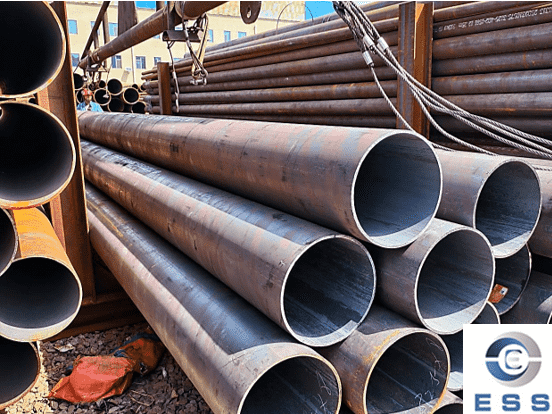

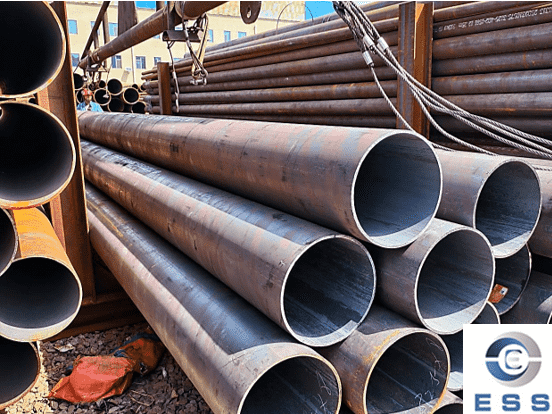

Seamless steel pipes are pipelines

with a hollow section and are used in large quantities for conveying fluids,

such as pipelines for conveying oil, natural gas, gas, water and certain solid

materials. Compared with solid steel such as round steel, steel pipe has a lighter

weight when the bending and torsion strength is the same. It is a kind of

economical cross-section steel and is widely used in pipeline engineering.

Seamless Steel Pipe Production Types

The production process of general seamless

steel pipes can be divided into two types: cold-rolled and hot-rolled.

In appearance, cold-rolled seamless steel

pipes are shorter than hot-rolled seamless steel pipes.

The wall thickness of cold-rolled seamless

steel pipes is generally higher than that of hot-rolled seamless steel pipes.

But the surface looks brighter than

thick-walled seamless steel pipes. There is not much roughness on the surface,

and there are not too many burrs on the caliber.

The maximum nominal diameter of cold rolled

pipe is 200 mm, and the maximum nominal diameter of hot rolled pipe is 600 mm.

Classification of Cold Rolled Pipes

Cold rolled pipes can be further classified into several types based on their material, manufacturing process, and application. Here are some common classifications:

1. Classification by Material

Carbon Cold Rolled Pipes: Steel tubes made from carbon steel through a cold-rolling process, possessing excellent mechanical and processing properties.

Alloy Cold Rolled Pipes: Made by adding alloying elements to carbon steel to improve its corrosion resistance, high-temperature resistance, or wear resistance, among other special properties.

Stainless Steel Cold Rolled Pipes: Made from stainless steel, possessing excellent corrosion resistance and aesthetic appeal, widely used in food, pharmaceutical, and chemical industries.

2. Classification by Manufacturing Process

Ordinary Cold Rolled Pipes: Steel pipes manufactured using conventional cold-rolling processes, suitable for general applications.

Precision Cold Rolled Pipes: Manufactured using more precise cold-rolling equipment and processes, possessing higher dimensional accuracy and surface finish, suitable for applications requiring high precision.

3. Classification by Application

Cold Rolled Pipes for Machinery: Primarily used in manufacturing mechanical parts, transmission components, etc., requiring high strength and rigidity.

Cold Rolled Pipes for Fluid Transportation: Used for transporting fluids such as water, oil, and gas, requiring good sealing and corrosion resistance.

Cold Rolled Pipes for Structural Applications: Used as supporting components in building structures, bridges, ships, etc., requiring high load-bearing capacity and stability.

Cold Rolled Pipe Pros and Cons

1. Advantages

The main advantage of cold rolled pipe is

the large reduction rate of section, especially the strong wall reduction

ability.

For carbon steel, the reduction rate of

cross-section in one rolling can reach 80%~83%, and for

alloy steel it can reach 72%~75%.

2. Disadvantage

The main disadvantage is the difficulty of

tool replacement. The cold rolling method is often used in combination with the

cold drawing method to produce cold-drawn billets, in addition to being

directly used to produce some of the cold-rolled pipes with higher precision.

This can not only give full play to the

wall reduction ability of cold rolling, but also cleverly use the advantages of

easy replacement of cold drawn tools, which is conducive to improving

productivity, expanding product production range and improving the surface

quality of steel pipes.

Cold Rolled Pipe Production

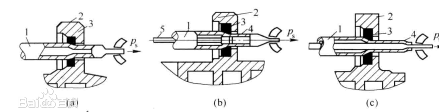

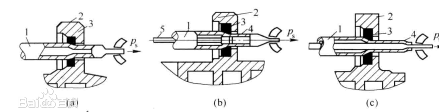

At present, the production of cold-rolled

pipes mostly uses periodic cold-rolled pipe mills. The working feature of the

periodic cold rolling pipe mill is that the steel pipe and the mandrel do not

move, and the reciprocating motion of the rack drives the reciprocating rolling

steel pipe, and uses variable-section-shaped compression rolling parts to

achieve the purpose of diameter reduction and wall reduction.

When the mill and roll are at the original

position a, the pass size is the largest (slightly larger than the outer

diameter of the blank); when the stroke limit position b is reached, the pass

is slightly larger than the outer diameter of the finished product; before the

position b is reached. The smallest is equal to the outer diameter of the

finished product.

At the original position a, the pipe

material is fed in, depending on the size of the rolling mill, each feeding is

3-30mm. At position b, the tube material is turned over 60°~90° each time, so that the pipe wall can be smoothed when the roller

returns.

After returning to the original position a,

feed the tube material to start the next cycle of rolling. The pipe material is

rolled repeatedly in this way, and finally the cold-rolled steel pipe of the

required size is rolled.

Cold Rolled Pipe Specification

The specification range of cold rolled

steel pipe is: outer diameter 4.0~450mm; wall thickness

0.04~60mm.

Compared with the cold drawing method, the

periodic cold rolled pipe method has the advantages of large pass area

shrinkage, no difficulty, and high yield: the disadvantage is that the

production speed is slow, the tool cost is expensive, and the intermediate

processing cost is just high.

Cold Rolled Seamless Steel Pipe

Cold rolled seamless steel pipe is a

seamless steel pipe rolled below its recrystallization temperature. During cold

rolling, steel is rolled at room temperature to form a seamless steel pipe of

the required shape and size. Because no phase transformation occurs during cold

rolling, its dimensional accuracy and surface finish are high.

1. Characteristics

Cold rolled seamless steel pipe has a

bright surface, high dimensional accuracy, and uniform wall thickness.

Due to the greater deformation resistance

of steel during cold rolling, the production cost of cold rolled seamless steel

pipe is higher, and its price is also relatively high.

Cold rolled seamless steel pipe is suitable

for applications requiring high dimensional accuracy and surface finish, such

as precision instruments, hydraulic systems, and pneumatic systems.

2. Applications

Machinery Manufacturing: As a raw material

for mechanical parts, such as shafts, sleeves, and bearings.

Hydraulic Equipment: Used to manufacture

hydraulic components and piping systems requiring high dimensional accuracy and

surface finish.

Structural Support: Due to its high

strength and good plasticity, it is often used as a supporting material for

various structures, such as bridges, buildings, and towers.

Production Steps of Cold Rolled Seamless

Steel Pipes

The production process of cold-rolled

seamless steel pipes mainly includes the following steps:

1. Billet Preparation

Select high-quality steel as raw material,

and perform cutting, rust removal, and other treatments to ensure the quality

and cleanliness of the raw materials.

2. Pickling and Lubrication

Pickle the billet to remove surface oxides

and dirt, and apply lubricant to reduce friction during rolling.

3. Cold Rolling

Continuously roll or cold draw the treated

steel using a cold rolling mill to form a seamless steel pipe. Strict control

of parameters such as temperature, pressure, and rolling speed is required

during this process to ensure the quality and precision of the steel pipe.

4. Heat Treatment

The formed steel pipe needs to undergo heat

treatment, such as annealing, to improve its mechanical properties and

corrosion resistance.

5. Straightening and Finishing

Straighten the heat-treated steel pipe to

eliminate defects such as bending and twisting, and perform finishing

processing to improve surface smoothness.

6. Inspection

The processed steel pipes undergo quality

inspection, including visual inspection, dimensional measurement, and

non-destructive testing, to ensure they meet relevant standards and

requirements.

Common Materials for Cold Rolled

Seamless Steel Pipes

Carbon structural steel (e.g., 10#, 20#,

45#)

Alloy structural steel (e.g., 20Cr, 40Cr,

20CrMo, 30CrMnSiA, 42CrMo)

Bearing steel (e.g., GCr15)

Stainless steel (Austenitic stainless steel

such as 304, 316L; Martensitic stainless steel such as 420; Ferritic stainless

steel such as 430, etc.)

Tool steel

Special alloys (e.g., Nickel-based alloys,

Titanium alloys, etc.)

Standards for Cold Rolled Seamless Steel

Pipes

1. Chinese National Standards (GB/T): such

as GB/T 3639 "Cold-Drawn or Cold-Rolled Precision Seamless Steel Pipes",

GB/T 8713 "Precision Inner Diameter Seamless Steel Pipes for Hydraulic and

Pneumatic Cylinders", etc.

2. International Standards (ISO): Such as

ISO 3304, ISO 3305, ISO 3306, etc., standards for precision seamless pipes.

3. German Industrial Standards (DIN): Such

as DIN 2391,

DIN 2393, etc.

4. American Society for Testing and

Materials (ASTM): Standards such as ASTM A519 (Seamless carbon and alloy steel

tubes for machine applications) and ASTM A269 (Seamless and welded austenitic

stainless steel tubes for general purposes) also include specifications for

cold-rolled products.

5. Japanese Industrial Standards (JIS):

Standards such as JIS G 3445 (Carbon

steel pipes for mechanical structures) and JIS G 3463 (Angle tubes for

general structural purposes) also cover requirements for cold-rolled precision

tubes.

6. Specialized Standards: Many downstream

industries (such as automotive, hydraulics, and bearings) have their own more

stringent enterprise or industry standards.

Specifications of Cold Rolled Seamless

Steel Pipes

The specifications of cold rolled seamless

steel pipes are generally marked according to their outer diameter and wall

thickness.

Common outer diameters include φ6mm, φ8mm, φ10mm, φ12mm, φ14mm, φ16mm, φ18mm, and φ20mm.

Wall thicknesses are generally 0.5mm,

0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm, and 3.0mm.

Custom thicknesses can also be made

according to customer requirements.

Mechanical Properties of Cold Rolled

Seamless Steel Pipes

The mechanical properties of cold rolled

seamless steel pipes include tensile strength, yield strength, and elongation.

Generally, tensile strength is required to

be above 400MPa, yield strength above 240MPa, and elongation above 15%. These

properties ensure the durability and safety of the pipe during use.

Procurement Guide

1. Don't Just Look at the Price

Many people choose hot-rolled pipes because

they're cheaper, but if high-precision applications are needed, this can

increase subsequent processing costs, making it a poor investment. Conversely,

choosing cold-rolled pipes for ordinary infrastructure applications is a waste

of money.

2. Check the Test Report

Request material certificates and test

reports from cold rolled steel pipe suppliers or manufacturers to confirm that

the steel pipe's chemical composition (such as carbon content and alloy element

content) and mechanical properties (tensile strength and yield strength) meet

the requirements.

3. Check the Surface Quality

Oxide scale is normal on the surface of hot

rolled pipes, but obvious cracks or dents indicate a defective product. For

cold rolled pipes, scratches or pitting on the surface indicate substandard

processing; do not purchase them.

Summary

Cold rolled seamless steel pipes, with

their high dimensional accuracy, excellent surface quality, outstanding

mechanical properties (especially strength), and unique ability to produce

small-diameter, thin-walled pipes, have become the preferred material for

high-end applications with stringent requirements for precision, performance,

and reliability.

Read more: The difference between cold drawn pipe and cold rolled pipe or Production process of seamless steel pipe

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.