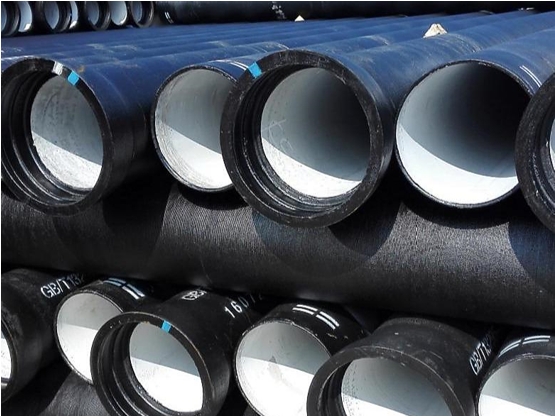

Eastern Steel Manufacturing Co., Ltd is a

steel company that produces ductile iron sewage pipes. The company has always

been committed to producing high-quality products and ensuring that only

high-quality raw materials are used to improve product performance.

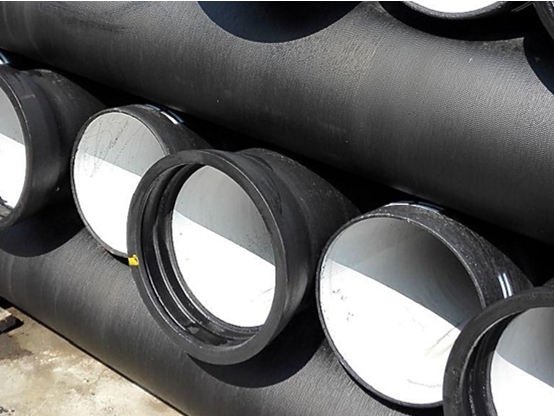

Ductile iron sewage pipe is a pipe made of

ductile iron material, mainly used to transport sewage. Ductile iron is a

special cast iron material characterized by graphite distributed in the matrix

in the form of spheres. This structure significantly reduces stress

concentration, thereby improving the strength and toughness of the material.

Here are specifications of some common model:

|

Model

|

Outer

diameter(mm)

|

Wall

thickness(mm)

|

|

DN50

|

63

|

5.5

|

|

DN75

|

90

|

6

|

|

DN100

|

118

|

6.5

|

|

DN125

|

145

|

7

|

|

DN150

|

170

|

7

|

|

DN200

|

222

|

8

|

|

DN250

|

274

|

8.5

|

|

DN300

|

326

|

9

|

|

DN350

|

378

|

9.5

|

|

DN400

|

429

|

10

|

|

DN450

|

480

|

10.5

|

|

DN500

|

532

|

11

|

|

DN600

|

635

|

12

|

|

DN700

|

738

|

13

|

|

DN800

|

842

|

14

|

|

DN900

|

945

|

15

|

Ductile iron sewage pipe has the following main characteristics:

1. High strength

The tensile strength of ductile iron sewage

pipe is usually between 400~700 MPa, which is much higher than the tensile

strength of traditional gray cast iron pipes.

2. Strong corrosion resistance

The inner wall is usually lined with cement

mortar, which can effectively resist the corrosion of sewage and extend the

service life.

3. High elongation

The elongation reaches more than 10%, and

it can withstand large external impact and deformation.

4. Good sealing

The pipe mouth adopts a flexible interface

design, which can effectively prevent sewage leakage.

5. Convenient construction

Pipeline connections usually adopt flexible

interfaces or flange connections, which are convenient and quick to construct

and adapt to complex terrain conditions.

Sewage pipes can be made of a variety of

materials, such as ductile iron, concrete, steel and plastic. However, ductile

iron has been widely used and recognized as a material choice for sewage pipes.

Ductile iron has excellent overall strength, but it is also prone to corrosion

and embrittlement. The addition of magnesium changes the microstructure of the

material and improves the mechanical properties of the material.

Ductile iron sewage pipes are made by

adding spheroidizing agent to cast iron above No. 18, and then centrifugally

casting at high speed through a centrifugal ductile iron casting machine. Heat

treatment and coating protection treatment are also carried out during the

production process to ensure the corrosion resistance and service life of the

pipe. Ductile iron pipes are suitable for sewage applications with a pH value

between 4.5-12.

This type of sewage pipe is widely used in the following

fields:

1. Urban drainage system

Used to collect and discharge rainwater,

sewage, etc., and can meet the needs of large drainage systems.

2. Sewage treatment projects

Sewage contains a variety of corrosive

substances. Ductile iron sewage pipes are widely used because of their strong

corrosion resistance.

Ductile iron sewage pipes are an ideal

choice and are usually used for large sewage mains and important trunk lines,

connecting adjacent pipes, and small pipes connecting specific residences and

businesses. Ductile iron sewage pipes are a time-tested solution in the field

of sewage treatment. Ductile iron sewage pipes are not a one-size-fits-all

solution because our customers have more choices.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.