Products: Drill Pipe, Heavy Weight Drill Pipe, Drill Collar

Size: 2-3/8"--6-5/8"

Standard: API 5DP

Grade: E75, G105, S135, SS-105, X95, X57, X75, X39

Length: Range 1, Range 2, Range 3

|

Drill pipe diameter

|

Drill pipe ID

|

Drill pipe weight

|

2-3/8 inch

|

1.815 inch

|

6.65 lb/ft

|

2-7/8 inch

|

2.151 inch

|

10.40 lb/ft

|

3-1/2 inch

|

2.764 inch, 2.602 inch

|

13.30 lb/ft, 15.50 lb/ft

|

4 inch

|

3.340 inch, 3.240 inch

|

14.00 lb/ft, 15.70 lb/ft

|

4-1/2 inch

|

3.826 inch, 3.640 inch

|

16.60 lb/ft, 20 lb/ft

|

5 inch

|

4.726 inch, 4.000 inch

|

19.50 lb/ft, 25.60 lb/ft

|

5-1/2 inch

|

4.778 inch, 4.670 inch

|

21.90 lb/ft, 24.70 lb/ft

|

6-5/8 inch

|

5.965 inch, 5.901 inch

|

25.20 lb/ft, 27.70 lb/ft

|

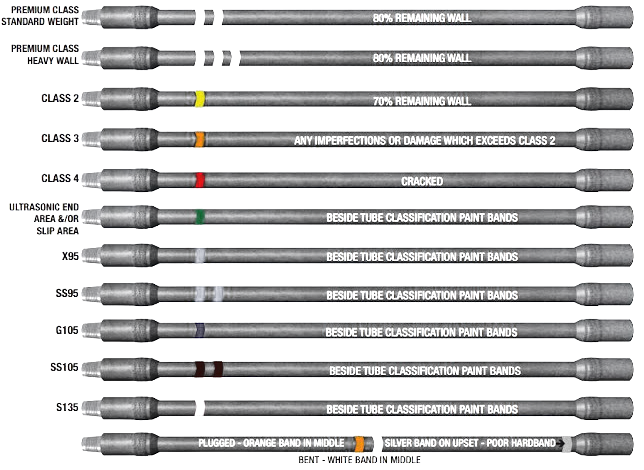

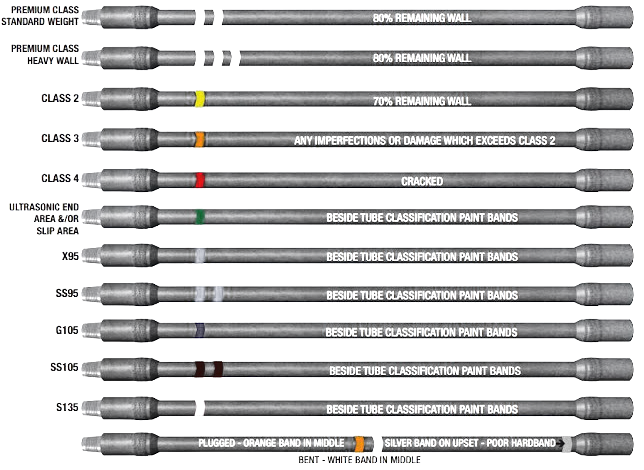

Drill pipe classfication

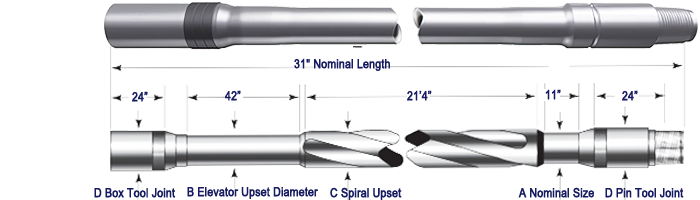

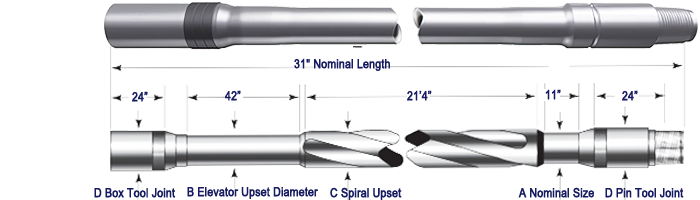

Upset of Drill Pipe

Internal Upset IU

External Upset EU

Internal-External Upset IEU

Thread/Connection Types of Drill Pipe

NC26, NC31, NC38, NC40, NC46, NC50, 5-1/2 FH, 6-5/8 FH

XT Connection of Drill Pipe

XT connections facilitate the use of larger drill pipe in a set hole size, such as 5⅞ in. drill pipe with XT 57 in an 8½ in. hole size.

X57, X75, X39, X95

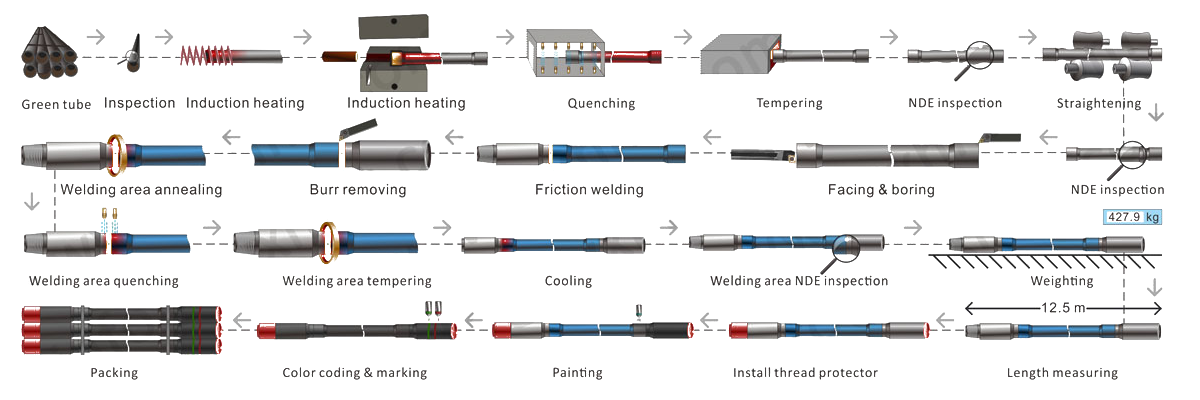

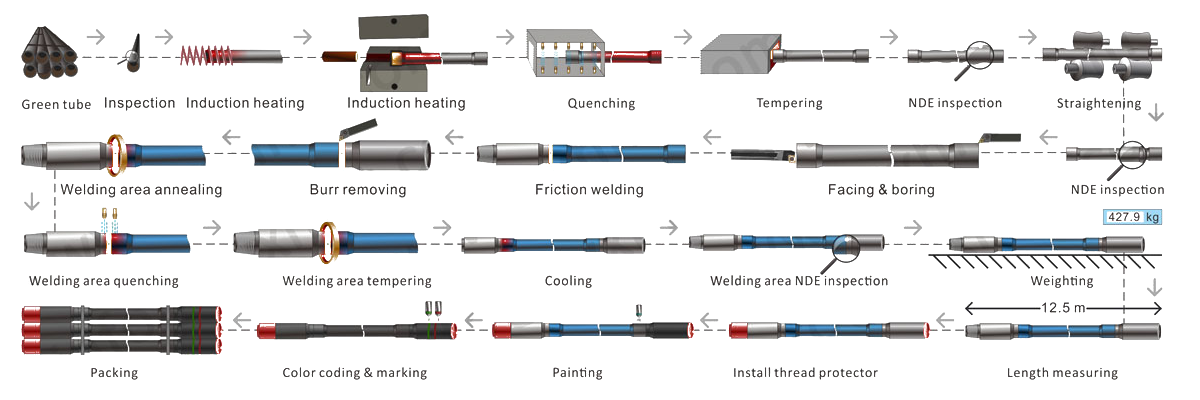

Details of manufacturing

Tool joints are inertia welded to the tubes with computer-monitored precision. Concentricity is carefully monitored and controlled, and the parameters of each weld are electronically recorded, and traceable to each joint. After removal of weld flash, the weld area is austenitized, quenched, and tempered to achieve the required mechanical properties. Heat treat cycles for each weld are compared to specific parameters and recorded for traceability. After all steps and machine marks are polished from the OD and ID area, hardness testing, ultrasonic testing, and wet magnetic particle inspections are used to verify the integrity of each weld zone.

Drilling pipe Application

Drill-pipe corrosion

Drill-pipe corrosion is a critical issue for any drilling operation, particularly under high-pressure, high-temperature downhole conditions. However, most laboratory studies have been conducted under ambient and static conditions, with only a few downhole studies based on flow loop showing inconsistent results. In this study, we proposed a novel simple method to simulate pipe corrosion/erosion in a reservoir-like environment under both the static and dynamic conditions and investigated the influences of wellbore conditions, including temperature, pressure and salinity of water-based drilling fluids, on the corrosion behaviour of the drill pipe. The results showed that the erosion effect of the drilling fluid (without drilled cuttings) was negligible. Furthermore, we found that the corrosion rate increased with an increase in the temperature, pressure and rotational speed; however, it decreased with an increase in the salinity. In addition, the proposed method can be used to simulate other complicated conditions.

|

Mechanical properties of API drill pipe grades

|

|

Grade

|

Yield strength

|

Tensile strength

|

API

|

|

psi

N/mm2

min.

|

psi

N/mm2

max.

|

psi

N/mm2

min.

|

|

E-75

|

75 000

515

|

105 000

725

|

100 000

690

|

Spec. 5 DP

|

|

X-95

|

95 000

655

|

125 000

860

|

105 000

725

|

Spec. 5 DP

|

|

G-105

|

105 000

725

|

135 000

930

|

115 000

795

|

Spec. 5 DP

|

|

S-135

|

135 000

930

|

165 000

1 140

|

145 000

1 000

|

Spec. 5 DP

|

|

Mechanical properties of API tool joint grades

|

|

Yield strength

|

Yield strength

|

Tensile strength

|

Elongation

|

Box

|

|

psi

N/mm2

min.

|

psi

N/mm2

max

|

psi

N/mm2

min

|

in 2 inches

%

min

|

Hardness

Brinell

min

|

|

120 000

827

|

165 000

1138

|

140 000

965

|

13

|

285

|

|

Chemical composition requirements

|

Pipe body

|

Phosphorus

max. %

|

Sulfur

max. %

|

|

Pipe body grade E

|

0.030

|

0.020

|

|

Pipe body grades X, G and S

|

0.020

|

0.015

|

|

Tool joint

|

0.020

|

0.015

|

Drill Pipe Dimensional Range and Performance Properties

|

Pipe Figures

|

|

Plant

|

NominalSize

|

NominalWeight

|

Wallthickness

|

InsideDiameter

|

Grade

|

Upset

|

TensileYield

|

TorsionalYield

|

InternalPressure

|

Collapse

|

|

in

|

lb/ft

|

in

|

in

|

lb

|

ft-lb

|

psi

|

psi

|

|

mm

|

kg/m

|

mm

|

mm

|

kN

|

Nm

|

bar

|

bar

|

|

3

|

2 3/8

60,3

|

6.65

9,34

|

0.280

7,11

|

1.815

46,13

|

E75

|

EU

|

138 214

615

|

6 250 8

474

|

15 474

1 067

|

15 599

1 075

|

|

6.65

9,34

|

0.280

7,11

|

1.815

46,13

|

Х95

|

EU

|

175 072

779

|

7 917 10

734

|

19 600

1 351

|

19 759

1 362

|

|

6.65

9,34

|

0.280

7,11

|

1.815

46,13

|

G105

|

EU

|

193 500

861

|

8 751 11

864

|

21 663

1 493

|

21 839

1 505

|

|

3

|

2 7/8

73,0

|

10.4

15,49

|

0.362

9,19

|

2.151

54,64

|

E75

|

EU

|

214 344

953

|

11 554

15 665

|

16 526

1 139

|

16 509

1 138

|

|

10.4

15,49

|

0.362

9,19

|

2.151

54,64

|

Х95

|

EU

|

271 503

1208

|

14 635

19 842

|

20 933

1 443

|

20 911

1 441

|

|

10.4

15,49

|

0.362

9,19

|

2.151

54,64

|

G105

|

EU

|

300 082

1335

|

16 176

21 932

|

23 137

1 595

|

23 112

1 593

|

|

10.4

15,49

|

0.362

9,19

|

2.151

54,64

|

S135

|

EU

|

385 820

1716

|

20 798

28 198

|

29 747

2 051

|

29 716

2 048

|

|

3

|

3 1/2

88,9

|

13.3

19,81

|

0.368

9,35

|

2.764

70,20

|

E75

|

EU

|

271 569

1208

|

18 551

25 152

|

13 800

951

|

14 113

973

|

|

13.3

19,81

|

0.368

9,35

|

2.764

70,20

|

Х95

|

EU

|

343 988

1530

|

23 498

31860

|

17 480

1 205

|

17 877

1 232

|

|

13.3

19,81

|

0.368

9,35

|

2.764

70,20

|

G105

|

EU

|

380 197

1691

|

25 972

35213

|

19 320

1 332

|

19 758

1 362

|

|

13.3

19,81

|

0.368

9,35

|

2.764

70,20

|

S135

|

EU

|

488 825

2174

|

33 392

45 273

|

24 840

1 712

|

25 404

1 751

|

|

15.5

23,09

|

0.449

11,4

|

2.602

66,10

|

E75

|

EU

|

322 775

1436

|

21 086

28 589

|

16 838

1 160

|

16 774

1 156

|

|

15.5

23,09

|

0.449

11,4

|

2.602

66,10

|

Х95

|

EU

|

408 848

1819

|

26 708

36 211

|

21 328

1 470

|

21 247

1 465

|

|

15.5

23,09

|

0.449

11,4

|

2.602

66,10

|

G105

|

EU

|

451 885

2010

|

29 520

40 023

|

23 573

1 625

|

23 484

1 619

|

|

15.5

23,09

|

0.449

11,4

|

2.602

66,10

|

S135

|

EU

|

580 995

2585

|

37 954

51 459

|

30 308

2 090

|

30 194

2 081

|

|

3

|

4

101,6

|

14.0

20,85

|

0.330

8,38

|

3.340

84,84

|

E75

|

IU

|

258 359

1269

|

23 288

31574

|

10 828

746

|

11 354

782

|

|

14.0

20,85

|

0.330

8,38

|

3.340

84,84

|

Х95

|

IU

|

361 454

1608

|

29 498

39 994

|

13 716

945

|

14 382

992

|

|

14.0

20,85

|

0.330

8,38

|

3.340

84,84

|

G105

|

IU

|

399 502

1777

|

32 603

44 204

|

15 159

1 045

|

15 896

1 096

|

|

Tool Joint Figures

|

Assembly

|

|

Connection

|

OutsideDiameter

|

InsideDiameter

|

TongLengthPin

|

TongLengthBox

|

TensileYield

|

TorsionalYield

|

Aprox. Weight

|

TorsionalRatio, pinto pipe

|

Make-uptorque

|

|

in

|

in

|

in

|

in

|

lb

|

ft-lb

|

lb/ft

|

ft-lb

|

|

mm

|

mm

|

mm

|

mm

|

kN

|

Nm

|

kg/m

|

Nm

|

|

NC26

|

3 3/8

85,725

|

1 3/4

27,15

|

7

177,8

|

8

203,2

|

313 681

1 395

|

6 875

9 321

|

6.99

10,41

|

1.10

|

4 125

5 593

|

|

NC26

|

3 3/8

85,725

|

1 3/4

27,15

|

7

177,8

|

8

203,2

|

313 681

1 395

|

6 875

9 321

|

7.11

10,59

|

0.87

|

4 125

5 593

|

|

NC26

|

3 3/8

85,725

|

1 3/4

27,15

|

7

177,8

|

8

203,2

|

313 681

1 395

|

6 875

9 321

|

7.11

1059

|

0.79

|

4 125

5 593

|

|

NC31

|

4 1/8

104,8

|

2 1/8

53,98

|

7

177,8

|

9

228,6

|

447 130

1 989

|

11 790

15 985

|

10.87

16,19

|

1.02

|

7 122

9 656

|

|

NC31

|

4 1/8

104,8

|

2

50,80

|

7

177,8

|

9

228,6

|

495 726

2 205

|

13 158

17 839

|

11.09

16,52

|

0.90

|

7 918

10 735

|

|

NC31

|

4 1/8

104,8

|

2

50,80

|

7

177,8

|

9

228,6

|

495 726

2 205

|

13 158

17 839

|

11.09

16,52

|

0.81

|

7 918

10 735

|

|

NC31

|

4 3/8

111,1

|

1 5/8

41,28

|

7

177,8

|

9

228,6

|

623 844

2 775

|

16 809

22 790

|

11.55

17,20

|

0.81

|

10 167

13 785

|

|

NC38

|

4 3/4

120,7

|

2 11/16

68,26

|

8

203,2

|

10 1/2

266,7

|

587 308

2 613

|

18 071

24 500

|

13.93

20,75

|

0.97

|

10 864

14 730

|

|

NC38

|

5

127,0

|

2 9/16

65,09

|

8

203,2

|

10 1/2

266,7

|

649 158

2 888

|

20 095

27 245

|

14.62

21,78

|

0.86

|

12 196

16 536

|

|

NC38

|

5

127,0

|

2 7/16

61,91

|

8

203,2

|

10 1/2

266,7

|

708 063

3 150

|

22 035

29 875

|

14.71

21,91

|

0.85

|

13 328

18 070

|

|

NC38

|

5

127,0

|

2 1/8

53,98

|

8

203,2

|

10 1/2

266,7

|

842 440

3 748

|

26 503

35 933

|

14.92

22,22

|

0.79

|

15 909

21 570

|

|

NC38

|

5

127,0

|

2 9/16

65,09

|

8

203,2

|

10 1/2

266,7

|

649 158

2 888

|

20 095

27 245

|

16.54

24,64

|

0.95

|

12 196

16 536

|

|

NC38

|

5

127,0

|

2 7/16

61,91

|

8

203,2

|

10 1/2

266,7

|

708 063

3 150

|

22 035

29 875

|

16.82

25,05

|

0.86

|

13 328

18 070

|

|

NC38

|

5

127,0

|

2 1/8

53,98

|

8

203,2

|

10 1/2

266,7

|

842 440

3 748

|

26 503

35 933

|

17.03

25,37

|

0.90

|

15 909

21 570

|

|

NC40

|

5 1/2

139,7

|

2 1/4

57,15

|

7

177,8

|

10

254,0

|

979 996

4 360

|

32 693

44 325

|

17.57

26,17

|

0.86

|

19 766

26 799

|

|

NC40

|

5 1/4

133,4

|

2 13/16

71,44

|

7

177,8

|

10

254,0

|

711 611

3 166

|

23 279

31 562

|

15.04

22,40

|

1.00

|

17 092

19 106

|

|

NC40

|

5 1/4

133,4

|

2 11/16

68,26

|

7

177,8

|

10

254,0

|

776 406

3 454

|

25 531

34 615

|

15.34

22,85

|

0.87

|

15 404

20 885

|

|

NC40

|

5 1/2

139,7

|

2 7/16

61,91

|

7

177,8

|

10

254,0

|

897 161

3 991

|

29 764

40 354

|

15.91

23,70

|

0.91

|

18 068

24 497

|

|

Pipe Figures

|

|

Plant

|

NominalSize

|

NominalWeight

|

Wallthickness

|

InsideDiameter

|

Grade

|

Upset

|

TensileYield

|

TorsionalYield

|

InternalPressure

|

Collapse

|

|

in

|

lb/ft

|

in

|

in

|

lb

|

ft-lb

|

psi

|

psi

|

|

mm

|

kg/m

|

mm

|

mm

|

kN

|

Nm

|

bar

|

bar

|

|

4

|

4 1/2

114,3

|

16.6

24,73

|

0.337

8,56

|

3.826

97,18

|

E75

|

IEU

|

330 558

1 470

|

30 807

41 774

|

9 829

678

|

10 392

717

|

|

16.6

24,73

|

0.337

8,56

|

3.826

97,18

|

X95

|

IEU

|

418 707

1 863

|

39 022

52 914

|

12 450

859

|

12 765

880

|

|

16.6

24,73

|

0.337

8,56

|

3.826

97,18

|

G105

|

IEU

|

462 781

2 059

|

43 130

58 484

|

13 761

949

|

13 825

953

|

|

16.6

24,73

|

0.337

8,56

|

3.826

97,18

|

S135

|

IEU

|

595 004

2 647

|

55 453

75 194

|

17 693

1 220

|

16 773

1157

|

|

20.00

29,79

|

0.430

10,92

|

3.64

92,46

|

E75

|

IEU

|

412 358

1 834

|

36 901

50 038

|

12 542

865

|

12 964

894

|

|

20.00

29,79

|

0.430

10,92

|

3.64

92,46

|

X95

|

IEU

|

522 320

2 323

|

46 741

63 381

|

15 886

1 096

|

16 421

1132

|

|

20.00

29,79

|

0.430

10,92

|

3.64

92,46

|

G105

|

IEU

|

577 301

2 568

|

51 661

70 052

|

17 558

1 211

|

18 149

1252

|

|

20.00

29,79

|

0.430

10,92

|

3.64

92,46

|

S135

|

IEU

|

742 244

3 302

|

66 421

90 067

|

2 2575

1 557

|

23 335

1609

|

|

4

|

5

127,0

|

19.50

29,05

|

0.362

9,19

|

4.276

108,62

|

E75

|

IEU

|

395 595

1 760

|

41 167

55 822

|

9 503

655

|

9 962

687

|

|

19.50

29,05

|

0.362

9,19

|

4.276

108,62

|

E75

|

IEU

|

395 595

1 760

|

41 167

55 822

|

9 503

655

|

9 962

687

|

|

19.50

29,05

|

0.362

9,19

|

4.276

108,62

|

X95

|

IEU

|

501 087

2 229

|

52 144

70 707

|

12 037

830

|

12 026

829

|

|

19.50

29,05

|

0.362

9,19

|

4.276

108,62

|

X95

|

IEU

|

501 087

2 229

|

52 144

70 707

|

12 037

830

|

12 026

829

|

|

19.50

29,05

|

0.362

9,19

|

4.276

108,62

|

G105

|

IEU

|

553 833

2 464

|

57 633

78 150

|

13 304

918

|

12 999

896

|

|

19.50

29,05

|

0.362

9,19

|

4.276

108,62

|

G105

|

IEU

|

553 833

2 464

|

57 633

78 150

|

13 304

918

|

12 999

896

|

|

19.50

29,05

|

0.362

9,19

|

4.276

108,62

|

S135

|

IEU

|

712 070

3 168

|

74 100

100 480

|

17 105

1180

|

15 672

1 081

|

|

19.50

29,05

|

0.362

9,19

|

4.276

108,62

|

S135

|

IEU

|

712 070

3 168

|

74 100

100 480

|

17 105

1180

|

15 672

1 081

|

|

25.60

38,13

|

0.50

12,70

|

4.000

101,60

|

E75

|

IEU

|

530 144

2 358

|

52 257

70 860

|

13 125

905

|

13 500

931

|

|

25.60

38,13

|

0.50

12,70

|

4.000

101,60

|

E75

|

IEU

|

530 144

2 358

|

52 257

70 860

|

13 125

905

|

13500

931

|

|

Tool Joint Figures

|

Assembly

|

|

Connection

|

OutsideDiameter

|

InsideDiameter

|

TongLengthPin

|

TongLengthBox

|

TensileYield

|

TorsionalYield

|

Aprox. Weight

|

TorsionalRatio, pinto pipe

|

Make-uptorque

|

|

in

|

in

|

in

|

in

|

lb

|

ft-lb

|

lb/ft

|

ft-lb

|

|

mm

|

mm

|

mm

|

mm

|

kN

|

Nm

|

kg/m

|

Nm

|

|

NC 46

|

6 1/4

158,8

|

3 1/4

82,55

|

7

177,8

|

10

254,0

|

901 164 4

009

|

33 228

45 057

|

18.37

27,35

|

1.09

|

20.396 27657

|

|

NC 46

|

6 1/4

158,8

|

3

76,20

|

7

177,8

|

10

254,0

|

1 048 426

4 664

|

38 998

52 881

|

18.79

27,98

|

1.01

|

20.396 27657

|

|

NC 46

|

6 1/4

158,8

|

3

76,20

|

7

177,8

|

10

254,0

|

1 048 426

4 664

|

38 998

52 881

|

18.79

27,98

|

0.91

|

23.795 32

266

|

|

NC 46

|

6 1/4

158,8

|

2 3/4

69,85

|

7

177,8

|

10 2

54,0

|

1 183 908

5 266

|

44 359

60 151

|

19.00

28,29

|

0.81

|

26.923 36

508

|

|

NC 46

|

6 1/4

158,75

|

3

76,20

|

7

177,8

|

10

254,0

|

1 048 426

4 664

|

38 998

52 881

|

22.09

32,89

|

1.07

|

23.795 32

266

|

|

NC 46

|

6 1/4

158,75

|

2 3/4

69,85

|

7

177,8

|

10

254,0

|

1 183 908

5 266

|

44 359

60 151

|

22.67

33,76

|

0.96

|

26.923 36

508

|

|

NC 46

|

6 1/4

158,75

|

2 1/2

63,50

|

7

177,8

|

10

254,0

|

1 307 608

5 817

|

49 297

66 847

|

22.86

34,03

|

0.96

|

29.778 40

379

|

|

NC 46

|

6 1/4

158,75

|

2 1/4

57,15

|

7

177,8

|

10

254,0

|

1 419 527

6 315

|

53 800

79 953

|

23.03

34,29

|

0.81

|

|

|

NC 50

|

6 5/8

168,28

|

3 3/4

95,25

|

7

177,8

|

10

254,0

|

939 095

4 177

|

37 269

50 537

|

20.85

31,05

|

0.92

|

22.836

30 966

|

|

51/2 FH

|

7

177,8

|

3 3/4

95,25

|

8

203,2

|

10

254,0

|

1 448 407

6 443

|

62 903

85 296

|

22.28

33,17

|

1.53

|

|

|

NC 50

|

6 5/8

168,28

|

3 1/2

88,90

|

7

177,8

|

10

254,0

|

1 109 920

4 937

|

44 456

60 282

|

21.45

31,94

|

0.86

|

27.076

36 715

|

|

51/2 FH

|

7

177,8

|

3 3/4

95,25

|

8

203,2

|

10

254,0

|

1 448 407

6 443

|

62 903

85 296

|

22.62

33,68

|

1.21

|

|

|

NC 50

|

6 5/8

168,28

|

3 1/4

82,55

|

7

177,8

|

10

254,0

|

1 268 963

5 645

|

51 217

69 450

|

21.93

32,65

|

0.89

|

31.025

42 070

|

|

51/2 FH

|

7

177,8

|

3 3/4

95,25

|

8

203,2

|

10

254,0

|

1 448 407

6 443

|

62 903

85 296

|

22.62

33,68

|

1.09

|

|

|

NC 50

|

6 5/8

168,28

|

2 3/4

69,85

|

7

177,8

|

10

254,0

|

1551706

6903

|

63 393

85 961

|

22.61

33,67

|

0.86

|

38.044

51 588

|

|

51/2 FH

|

7 1/4

184,15

|

3 1/2

88,90

|

8

203,2

|

10

254,0

|

1 619 231

7 203

|

72 213

97 921

|

23.48

34,96

|

0.98

|

43.490

58 972

|

|

NC 50

|

6 5/8

168,28

|

3 1/2

88,90

|

7

177,8

|

10

254,0

|

1 109 920

4 937

|

44 156

59 876

|

26.85

39,98

|

0.86

|

27.076

36 715

|

|

51/2 FH

|

7

177,8

|

3 1/2

88,90

|

8

203,2

|

10

254,0

|

1 619 231

7 203

|

62 903

85 296

|

28.27

42,09

|

1.21

|

37.742

51 178

|

|

Pipe Figures

|

|

Plant

|

NominalSize

|

NominalWeight

|

Wallthickness

|

InsideDiameter

|

Grade

|

Upset

|

TensileYield

|

TorsionalYield

|

InternalPressure

|

Collapse

|

|

in

|

lb/ft

|

in

|

in

|

lb

|

ft-lb

|

psi

|

psi

|

|

mm

|

kg/m

|

mm

|

mm

|

kN

|

Nm

|

bar

|

bar

|

|

4

|

5

127,0

|

25.60

38,13

|

0.50

12,70

|

4.000

101,60

|

X95

|

IEU

|

671 515

2 987

|

66 192

89 756

|

16 625

1 147

|

17 100

1179

|

|

25.60

38,13

|

0.50

12,70

|

4.000

101,60

|

X95

|

IEU

|

671 515

2 987

|

66 192

89 756

|

16 625

1 147

|

17 100

1179

|

|

25.60

38,13

|

0.50

12,70

|

4.000

101,60

|

G105

|

IEU

|

742 201

3 302

|

73 159

99 204

|

18 375

1 267

|

18 900

1303

|

|

25.60

38,13

|

0.50

12,70

|

4.000

101,60

|

G105

|

IEU

|

742 201

3 302

|

73 159

99 204

|

18 375

1 267

|

18 900

1303

|

|

25.60

38,13

|

0.50

12,70

|

4.000

101,60

|

S135

|

IEU

|

954 259

4 245

|

94 062

127 548

|

23 625

1 629

|

24 300

1676

|

|

4

|

5 1/2

139,7

|

21.90

32,62

|

0.361

9,17

|

4.778

121,36

|

E75

|

IEU

|

437 116

1 944

|

50 710

68 763

|

8 615

594

|

8 413

580

|

|

21.90

32,62

|

0.361

9,17

|

4.778

121,36

|

X95

|

IEU

|

553 681

2 463

|

64 233

87 100

|

10 912

753

|

10 019

691

|

|

21.90

32,62

|

0.361

9,17

|

4.778

121,36

|

G105

|

IEU

|

611 963

2 722

|

70 994

96 258

|

12 061

832

|

10 753

742

|

|

21.90

32,62

|

0.361

9,17

|

4.778

121,36

|

S135

|

IEU

|

786 809

3 500

|

91 278

123 773

|

15 507

1 069

|

12 679

874

|

|

24.70

36,79

|

0.415

10,54

|

4.670

118,62

|

E75

|

IEU

|

497 222

2 212

|

56 574

76 714

|

9 903

683

|

10 464

722

|

|

24.70

36,79

|

0.415

10,54

|

4.670

118,62

|

X95

|

IEU

|

629 814

2 802

|

71 660

97 171

|

12 544

865

|

12 933

892

|

|

24.70

36,79

|

0.415

10,54

|

4.670

118,62

|

G105

|

IEU

|

696 111

3 097

|

79 204

107 401

|

13 865

956

|

14 013

966

|

|

24.70

36,79

|

0.415

10,54

|

4.670

118,62

|

S135

|

IEU

|

894 999

3 981

|

101 833

138 086

|

17 826

1229

|

17 023

1 174

|

|

Tool Joint Figures

|

Assembly

|

|

Connection

|

OutsideDiameter

|

InsideDiameter

|

TongLengthPin

|

TongLengthBox

|

TensileYield

|

TorsionalYield

|

Aprox. Weight

|

TorsionalRatio, pinto pipe

|

Make-uptorque

|

|

in

|

in

|

in

|

in

|

lb

|

ft-lb

|

lb/ft

|

ft-lb

|

|

mm

|

mm

|

mm

|

mm

|

kN

|

Nm

|

kg/m

|

Nm

|

|

NC 50

|

6 5/8

168,28

|

3

76,20

|

7

177,8

|

10

254,0

|

1 416 225

6 300

|

57 534

78 016

|

27.87

41,50

|

0.86

|

34.680

47026

|

|

51/2 FH

|

7

177,8

|

3 1/2

88,90

|

8

203,2

|

10

254,0

|

1 619 231

7 203

|

62 903

85 296

|

28.59

42,57

|

0.95

|

37.742

51178

|

|

NC 50

|

6 5/8

168,28

|

2 3/4

69,85

|

7

177,8

|

10

254,0

|

1 619 231

7 203

|

63 393

85 961

|

28.32

42,17

|

0.87

|

38.044

51588

|

|

51/2 FH

|

7 1/4

184,15

|

3 1/2

88,90

|

8

203,2

|

10

254,0

|

1 551 706

6 903

|

72 213

97 921

|

29.16

43,42

|

0.99

|

43.490

58972

|

|

51/2 FH

|

7 1/4

184,15

|

3 1/4

82,55

|

8

203,2

|

10

254,0

|

1 778 274

7 910

|

78 716

106 739

|

29.43

43,82

|

0.83

|

47.230

64044

|

|

51/2 FH

|

7

177,8

|

4

101,60

|

8

203,2

|

10

254,0

|

1 265 802

5 631

|

55 687

75 512

|

23.77

35,39

|

1.11

|

33.560

45507

|

|

51/2 FH

|

7

177,8

|

3 3/4

95,25

|

8

203,2

|

10

254,0

|

1 448 407

6 443

|

62 903

85 296

|

24.53

36,53

|

0.98

|

37.742

51178

|

|

51/2 FH

|

7 1/4

184,15

|

3 1/2

88,9

|

8

203,2

|

10

254,0

|

1 619 231

7 203

|

72 213

97 921

|

25.38

37,79

|

1.02

|

43.490

58972

|

|

51/2 FH

|

7 1/2

190,50

|

3

76,20

|

8

203,2

|

10

254,0

|

1 925 536

8 566

|

86 765

117 653

|

26.50

39,46

|

0.96

|

52.302

70922

|

|

51/2 FH

|

7

177,8

|

4

101,60

|

8

203,2

|

10

254,0

|

1 265 802

5 631

|

55 687

75 512

|

26.33

39,21

|

0.99

|

33.560

45507

|

|

51/2 FH

|

7 1/4

184,15

|

3 1/2

88,9

|

8

203,2

|

10

254,0

|

1 619 231

7 203

|

72 213

97 921

|

27.85

41,47

|

1.01

|

43.490

58972

|

|

51/2 FH

|

7 1/4

184,15

|

3 1/2

88,9

|

8

203,2

|

10

254,0

|

1 619 231

7 203

|

72 213

97 921

|

27.85

41,47

|

0.92

|

43.490

58972

|

|

51/2 FH

|

7 1/2

190,50

|

3

76,20

|

8

203,2

|

10

254,0

|

1 925 536

8 566

|

86 765

117 653

|

27.77

41,35

|

0.86

|

52.302

70922

|

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.