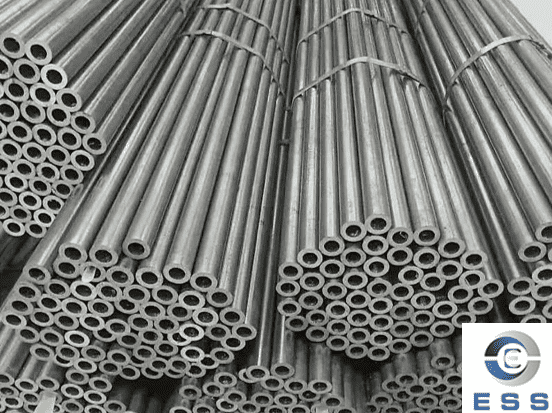

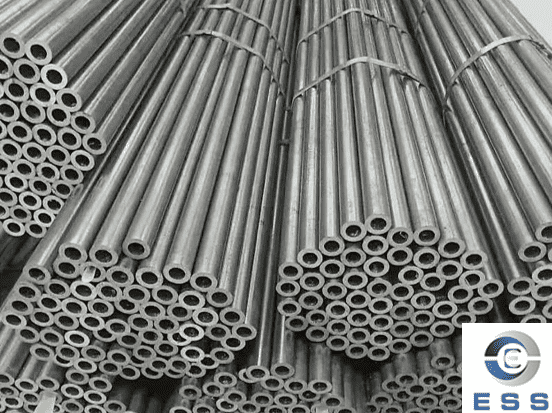

Small-diameter seamless

steel pipes typically refer to seamless steel pipes with an outer

diameter less than 89 mm and greater than 4 mm. They are widely used in

machinery manufacturing, hydraulic systems, automotive parts, precision

instruments, and fluid transport systems. These pipes are known for their high

dimensional accuracy, uniform wall thickness, high strength, and good surface

finish, making them one of the most common precision pipe materials to replace

welded pipes.

Using small-diameter seamless steel pipes

(especially those manufactured using cold drawing/cold rolling processes) can

significantly improve product processing efficiency, reduce machining workload,

increase material utilization, and enhance the overall operational stability of

equipment.

Specifications of Small-Diameter Seamless

Steel Pipes

The specifications of small-diameter

seamless steel pipes typically refer to their outer diameter and wall

thickness. The outer diameter range is generally 4 mm to 89 mm, and the wall

thickness range is generally 2 mm to 10 mm.

1. Outer Diameter Range (OD)

Hot-rolled

pipes: Generally cover medium diameters, but

less common in the small diameter range.

Cold-drawn/cold-rolled

pipes: This is the main production method for

small-diameter seamless pipes, offering a variety of specifications.

Common range: Φ6mm

to Φ89mm (minimum Φ3mm; maximum Φ114mm and above).

2. Wall Thickness Range (WT)

Wall thickness is related to the "pipe

diameter class" (e.g., Sch40, Sch80), but for small diameter pipes, the

wall thickness value is usually checked directly.

Ultra-thin wall: Up to 0.5mm (for precision

instruments).

Common wall thickness: 1.0mm to 5.0mm

(e.g., a 25mm diameter pipe can have wall thicknesses of 1.5mm, 2.0mm, 2.5mm,

3.0mm, etc.).

Thick/Extra-thick wall: We can provide wall

thicknesses much greater than welded pipe specifications. For example,

"thick-walled seamless pipes" for small diameter hydraulic cylinders

can have wall thicknesses of up to 10mm or even thicker.

3. Common Size for Small-Diameter Seamless

Steel Pipes

The theoretical weight of small-diameter

seamless steel pipes is calculated using the formula:

W = 0.02466 × Wall Thickness × (Outer

Diameter − Wall Thickness)

kg/m

|

Outer Diameter (mm)

|

Common Wall Thickness (mm)

|

Theoretical Weight (kg/m)

|

Material

|

|

6

|

1.0, 1.5

|

0.12, 0.17

|

20#

|

|

10

|

1.5, 2.0

|

0.31, 0.40

|

304

|

|

25

|

2.0, 3.0

|

1.13, 1.63

|

20#

|

|

38

|

2.5, 4.0

|

2.19, 3.35

|

316L

|

|

57

|

3.0, 5.0

|

3.99, 6.41

|

20#

|

|

89

|

4.0, 6.0

|

8.38, 12.28

|

Q345

|

Applications of Small Diameter Seamless

Steel Pipes

1. Fluid Transportation: Water Pipes, Oil

Pipes, Gas Pipes

1) Water Pipe Systems

Household/Building Water Supply:

OD: 20–32mm

WT: 2–3mm

Material: 304, 316L, 20#

Industrial Water Supply/High-Pressure Water

Lines:

OD: 50–76mm

WT: 3–5mm

2) Oil Pipelines (Hydraulic, Lubricating,

Fuel Oil)

Common Hydraulic Circuit Specifications:

OD 12mm–38mm, WT 1–3mm (DIN 2391-1

Precision Steel Tube)

Aerospace Fuel/Lubricating Oil Systems:

OD 20mm–60mm, WT

1.5–4mm, materials are mostly 304 / 316L / Ti alloys

3) Gas Pipelines (Natural Gas, Industrial

Gas)

Specifications are affected by pressure

rating:

OD: 12–50mm

WT: 1–3mm

Standard: GB/T 8163, ASTM A106, DIN 2391

2. Hydraulic Systems and Mechanical

Structural Components (Highest Proportion)

Hydraulic supports, hydraulic cylinders,

hydraulic line connectors

Automotive fuel lines, brake lines

High-pressure hydraulic lines for

construction machinery

Common specifications: Φ10mm, Φ16mm, Φ18mm, Φ25mm, Φ32mm

3. Precision Instruments and

High-Requirement Parts

Sensor housings

Bearing rings

Automotive shock absorber inner tubes

Medical device components

Commonly used: Ultra-thin wall 0.5–1.0 mm precision seamless tubes (DIN 2391 precision grade)

4. Power Systems (Cable Protection

Conduits)

OD: 15–40mm

WT: 2–4mm

Common materials: Q235, Q345, 20#

Suitable for substations, ultra-high

voltage lines, and industrial power distribution conduits.

Common Standards for Small-Diameter

Seamless Steel Pipes

|

Standard

|

Applicable Fields

|

|

ASTM A106

|

Seamless

carbon steel pipes for high-temperature applications

|

|

ASTM A179

|

Seamless cold-drawn mild

steel tubes for heat exchangers and condensers.

|

|

ASTM A513

|

Mechanical structures, precision

components

|

|

DIN 2391(St35/St37/St52)

|

Precision seamless steel tubes (St

series, extremely high dimensional accuracy)

|

|

EN 10305-1

|

Cold-drawn precision tubes

|

|

GB/T 3639

|

Cold-drawn or cold-rolled precision

seamless steel tubes

|

|

GB/T 8163

|

Seamless steel tubes for fluid transport

|

How to Choose the Right Small-Diameter

Seamless Steel Pipe?

1. Hydraulic systems

DIN 2391 St52 / EN10305-1 E355, Φ10–Φ50, WT 1.5–4mm

seamless steel tubes are suitable.

Because of their high strength, high

precision, and rust-proof phosphate/galvanized surface treatment.

2. Food Machinery/Medical Equipment

304/316L seamless steel pipe, Φ6–Φ38, WT 1–2mm, is

a good choice due to its corrosion resistance, polishability, and hygiene

compliance.

3. High-Temperature Conveying

ASTM A106 Gr.B/C seamless steel pipe, Φ20–Φ89, WT 3–6mm, is

a good choice due to its excellent temperature resistance.

4. Precision Instruments

Ultra-thin wall precision tubes, Φ3–Φ20, are a good choice due to their high

dimensional accuracy and wall thickness down to 0.5mm.

5. Industrial Structural Components

Q345/20# seamless steel pipe, Φ20–Φ89, is a good choice due to its high

strength and reasonable price.

FAQ

Small-diameter seamless steel pipes have no

weld seams, offering higher pressure resistance and more uniform performance,

making them suitable for precision hydraulic systems and high-pressure

conditions.

Seam pipes, on the other hand, are lower in

cost and used in general structures and medium-to-low-pressure systems.

2. What Sizes Do Seamless Pipes Come in?

Common sizes for seamless pipes include

1/2" SCH 80, 3/4" SCH 40, 3/4" SCH 80, and 1" SCH 40. Here

is a table of seamless

steel pipe sizes.

Summary

In short, small-diameter seamless steel

pipes are widely used in various fields due to their high precision, strength,

uniform wall thickness, and excellent pressure resistance. They occupy a key

position in industries such as hydraulics, machinery manufacturing, automotive,

and fluid transportation. Their specifications and applications vary depending

on the specific application.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.