Cold-drawn and cold

rolled pipes, as two common steel pipe processing methods, play

important roles in industrial production. Although their names are similar and

both fall under the category of cold working, their production processes,

surface quality, dimensional accuracy, quality control, mechanical properties,

processing temperatures, and application areas differ significantly. These

differences will be analyzed in detail below.

Commonalities between Cold Drawn and

Cold Rolled Pipes

Both processes significantly improve

material properties through room-temperature deformation:

1. Increased Strength

Cold deformation refines the grain size,

increasing tensile strength by 20%-30% compared to the raw material.

2. Improved Surface Quality

Both processes achieve a smooth surface

with Ra≤1.6μm, superior to the

Ra≥12.5μm of hot

rolled pipes.

3. Dimensional Accuracy

Outer diameter tolerances are generally 3-5

grades better than hot rolled pipes, making them particularly suitable for

precision fitting applications such as hydraulic cylinders.

4. Common Limitations of Cold Working

Due to work hardening, the plasticity

indicators (such as elongation) of finished pipes are typically 15%-25% lower

than those of hot-rolled pipes. For complex forming, intermediate annealing is

required to restore processing performance.

1. Manufacturing Process

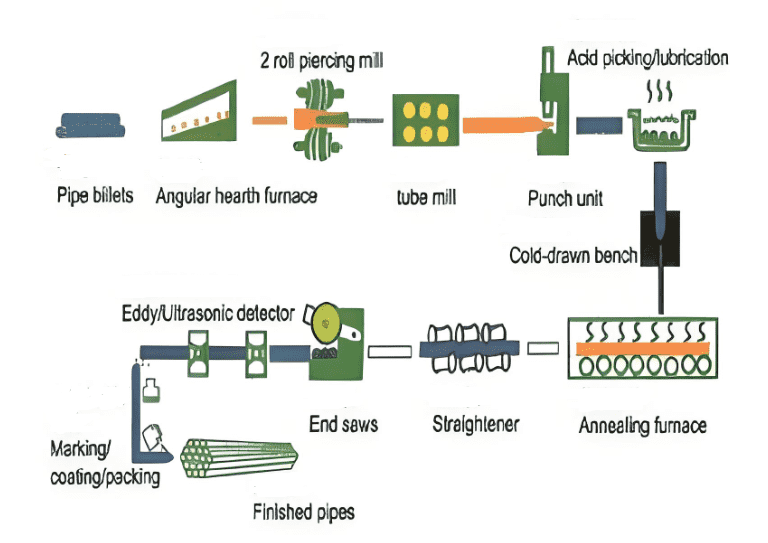

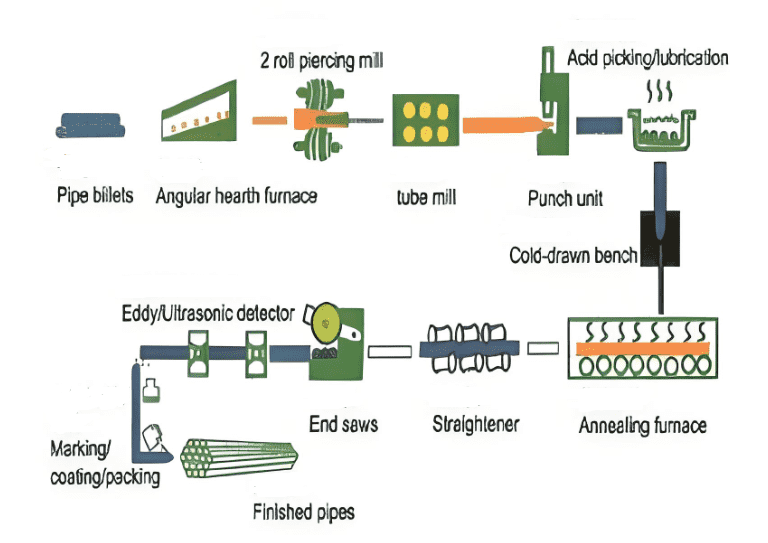

Cold drawn pipe manufacturing is carried

out on a cold-drawing machine. The billet steel pipe is heated to a certain

temperature and then pressed through a die, subjecting the steel pipe to

tensile stress on both the inner and outer sides simultaneously. Under tension,

the diameter and wall thickness of the steel pipe both decrease until the

desired size is achieved.

Cold drawn process: Round billet → Pickling → Lubrication → Multi-pass drawing → Annealing (stress

relief) → Straightening;

Cold rolled pipe manufacturing involves

heating the billet steel pipe to a certain temperature and then rolling it.

Unlike cold-drawn pipes, cold rolled pipes undergo only unidirectional

extrusion during rolling, and the radial dimensions and wall thickness of the

steel pipe do not change significantly. Therefore, the manufacturing cost of

cold-rolled pipes is relatively lower than that of cold-drawn pipes.

Cold rolled process: Hot-rolled pipe → Pickling → Continuous rolling on a cold

rolling mill → Online inspection → Finishing.

2. Dimensional Accuracy

Cold drawn steel pipes typically achieve an

outer diameter accuracy of ±0.1mm and a wall thickness

tolerance of around ±5%, making them suitable for

producing pipes with smaller diameters (usually ≤150mm)

and larger length-to-diameter ratios.

Cold rolled steel pipes offer even greater

advantages in dimensional control, with an outer diameter accuracy of ±0.05mm and a wall thickness tolerance controlled within ±3%, making them particularly suitable for producing precision

hydraulic pipes, bearing pipes, and other dimensionally sensitive products.

3. Surface Quality

Cold drawn pipes often have longitudinal

striations on their surface, with a roughness Ra value typically ranging from

1.6 to 3.2μm. Cold rolled pipes, on the other hand,

have a smoother surface, with an Ra value reaching 0.4-0.8μm when using high-precision rolls.

This difference gives cold rolled pipes an

advantage in applications such as surface coating and precision fitting.

However, it is worth noting that the cold rolling process may produce unique

"rolling marks," which need to be controlled by optimizing the mill

rigidity and process parameters.

4. Mechanical Properties

Cold drawn pipes possess higher axial

strength and hardness, making them suitable for manufacturing components

subjected to axial loads.

Cold rolled pipes, due to uniform work

hardening, combine good strength and plasticity, and their fatigue performance

is generally superior to that of cold-drawn pipes.

5. Key Quality Control Points

Cold drawing steel production requires

close attention to die wear, lubrication, and drawing force fluctuations; cold rolling

steel production, on the other hand, requires more precise control over the

matching of roll gap, feed rate, and rotation speed.

Statistical Process Control (SPC) data

shows that the critical dimension CPK value of cold rolling is typically

0.2-0.3 higher than that of cold drawing, indicating better process stability.

6. Processing of Special Materials

Cold rolling is more advantageous for

difficult-to-deform materials such as high-strength alloy steel and titanium

alloys. Its multi-directional stress state effectively prevents crack

formation.

Cold drawing often requires more

intermediate annealing cycles when processing these materials.

7. Residual Stress Distribution

Residual stress distribution is a key

factor affecting product stability.

The residual stress in cold drawn steel

pipes exhibits a distinct layered distribution, with the surface in a tensile

stress state. Cold rolled steel pipes, due to more uniform deformation, show

lower peak residual stress and a more gradual distribution.

This difference makes cold-drawn pipes more

prone to deformation during subsequent processing, requiring stress-relief

annealing to improve this. A precision hydraulic system manufacturer's tests

found that the straightness stability of cold-rolled pipe fittings was more

than 35% higher than that of cold-drawn products.

8. Different Processing Temperatures

The processing temperatures for cold

rolling and cold drawing also differ. Cold rolling is performed below the

crystallization temperature, generally at room temperature, while cold drawing

is performed under heating conditions at approximately 800°C to 950°C.

Therefore, cold drawing requires heating

the steel pipe in a furnace before sending it to a drawing machine for

processing, ensuring that defects such as cracks do not appear on the steel

pipe surface.

9. Application Areas

Cold-drawn pipes are used in the

manufacture of precision mechanical parts, automotive components, pipes,

hydraulic cylinder housings, diesel engine fuel injection pumps, and other

high-precision steel products.

Cold rolled pipes are used to manufacture

general steel products such as low- and medium-pressure boiler pipes, hydraulic

supports, automobile axle sleeves, automobile bearing housings, and bicycle

frames.

Pros and Cons of Cold Drawn Seamless

Pipe

1. Cold Drawn Seamless Pipe Pros

Improved Mechanical Properties: The cold drawing

process allows for greater plastic deformation of the steel pipe, thereby

improving its toughness and tensile strength, resulting in better mechanical

properties.

High Dimensional Accuracy: The cold drawing

process allows for precise control of the seamless

steel pipe sizes, meeting the requirements of high-precision

applications.

Good Surface Quality: The surface of the

seamless pipe is less prone to oxide scale formation during cold drawing,

resulting in better surface quality, which is beneficial for subsequent

processing and use.

2. Cold Drawn Seamless Pipe Cons

Large Residual Stress: During cold drawing,

significant residual stress is generated inside the seamless pipe, which may

affect its overall and local buckling characteristics.

Limited Drawing Length: Due to the presence

of residual stress, the length of cold-drawn seamless steel pipes is limited

and cannot be drawn too long.

Higher Cost: The cold drawing process is

relatively complex and requires advanced equipment and technology, resulting in

relatively high production costs.

Pros and Cons of Cold Rolled Seamless Pipes

1. Cold Rolled Seamless Pipe Pros

High Forming Speed and Output: Cold rolling

allows for rapid forming at room temperature, resulting in high production

efficiency and no damage to the coating.

Diverse Cross-Sectional Shapes: Cold

rolling can produce a variety of cross-sectional shapes to adapt to different

application conditions.

Increased Yield Point: The cold rolling

process induces plastic deformation in the seamless pipe, thereby increasing

its yield point and enhancing the material's load-bearing capacity.

2. Cold Rolled Seamless Pipe Cons

Residual Stress: Although there is no hot

plastic compression during cold rolling, residual stress still exists within

the cross-section, which may affect the performance of the steel pipe.

Poor Torsional Resistance: Cold rolled

steel sections are generally open, resulting in lower free torsional stiffness

and relatively poor torsional resistance.

Smaller Wall Thickness: Cold rolled steel

has a thinner wall thickness, and there is no thickening at the corners where

plates meet, making it less able to withstand localized concentrated loads.

How to Choose?

1. Diameter Range

Cold-drawn pipes are better suited for

diameters of Φ6-127mm, while cold rolled pipes excel in

the Φ4-80mm thin-walled pipe segment.

2. Batch Size Requirements

Cold drawing offers high single-batch

forming efficiency, suitable for small to medium batches; cold rolling is

suitable for large-volume precision orders.

3. Cost Control

Cold drawn pipes are 8%-12% cheaper for the

same specifications, but cold rolling is more economical for ultra-thin walls

(<1mm).

4. Subsequent Processing

Cold rolled pipes are preferred for deep

drawing due to their lower anisotropy.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.