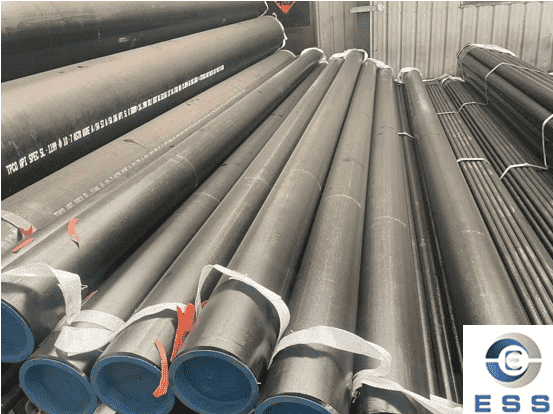

ASTM A106 Gr B seamless

pipe is a type of carbon steel seamless pipe used in high-temperature,

high-pressure applications, widely used in oil, natural gas, chemical, power,

and industrial piping systems. This article analyzes ASTM A106 Gr B seamless

pipe from aspects such as standard definition, material properties,

manufacturing and processing technology, quality control, equivalent materials,

and typical applications.

What is ASTM A106 Gr B?

"ASTM 106B pipe" refers to

seamless pipe that has been hot-rolled or cold-drawn (rolled). Seamless pipes

used in high-temperature environments conform to the ASTM A106 standard

specification. Therefore, it can be used to transport fluids (such as water,

oil, gas, or slurry), making it a critical component of the mining industry.

What is the Difference between SA 106 Gr

B and A106 Gr B?

ASTM A106 Gr B and ASME SA106 Gr B are

completely identical in chemical composition and mechanical properties. The

only differences are:

ASTM A106: Material standard;

ASME SA106: Approval standard for pressure

equipment (boilers, pressure piping).

Standards for Manufacturing ASTM A106

Steel Pipes

1. ASTM General and Testing Standards

ASTM A530 / A530M: General Requirements for

Carbon and Alloy Steel Pipes

ASTM E213: Ultrasonic Testing (UT)

ASTM E309: Eddy Current Testing (ET)

ASTM E381: Macroscopic Corrosion Test

Methods

ASTM E570: Magnetic Flux Leakage Testing

(MFL)

2. ASME Size Standards

ASME

B36.10M: Nominal Dimensions of Welded and

Seamless Steel Pipes (NPS & Schedule)

3. Surface Treatment and Marking

SSPC-SP 6: Commercial Grade Sandblasting

MIL-STD-129 / Fed.Std.123: Packaging and

Marking Specifications (Commonly Used for Export)

Material Properties of ASTM A106 Gr B

Seamless Pipes

1. Strength and Toughness

ASTM A106 Gr B seamless pipes have high

tensile strength and yield strength, enabling them to withstand large pressure

and impact loads, making them suitable for high-pressure environments.

2. Temperature Resistance

This material can operate stably within a

certain temperature range and is generally suitable for medium and low

temperature environments, but caution should be exercised when using it at high

temperatures.

3. Corrosion Resistance

As it is carbon steel, its corrosion

resistance is relatively limited. When used in humid or corrosive environments,

protective measures such as coatings or plating should be considered.

ASTM A106 Gr BChemical Composition

Carbon max. %: 0.30

Manganese %: 0.29 to 1.06

Phosporous, max. %: 0.025

Sulfur, max. %: 0.025

Silicon, min. %: 0.10

ASTM A106 Gr B Pipe Mechanical Property

Yield strength (Rp0.2): ≥ 205 MPa

Tensile strength (Rm): 415–550 MPa

Elongation (A): ≥ 30 %

ASTM A106 Gr B Seamless Pipes Dimensions

Nominal Size: NPS 1/8 – NPS 48

Outer Diameter: OD 10.3 – 1219 mm

Wall Thickness: SCH 10 – SCH XXS

Length: Fixed Length / Random Length /

Customization

ASTM A106 Gr B Seamless Pipe Processing

Technology

1. Cutting and Blanking

Specialized

equipment, such as a band saw or circular saw, must be used during cutting to

ensure a clean, burr-free cut. For thick-walled tubes, beveling is recommended

for subsequent welding. Feed speed must be controlled during cutting to prevent

overheating and microstructural changes.

2. Bending and Forming

Cold bending is suitable for thin-walled

tubes. The bending radius must meet specifications to prevent wrinkles or

elliptical deformation. Hot bending is suitable for thick-walled tubes. The

heating temperature should be controlled below the material's phase

transformation point, and slow cooling is required after forming. Regardless of

the process used, a die must be used to ensure dimensional accuracy during

bending.

3. Welding

Before welding, the bevel must be cleaned

to remove oil and oxide layers. A combination of tungsten inert gas (TIG)

welding for the root pass and shielded metal arc welding (SMAW) for the cover

pass is recommended. Welding parameters should be adjusted according to the

wall thickness, and interpass temperature should be strictly controlled. For

critical welds, post-weld heat treatment is required to eliminate residual

stress.

4. Heat Treatment Process

Normalizing can refine the grain and

improve the material's toughness. During treatment, ensure uniform temperature

within the furnace; the holding time should be calculated based on the wall

thickness. The cooling stage should be performed naturally in still air to

avoid excessively rapid cooling that could lead to abnormal hardness.

ASTM A106 Gr B Seamless Pipe Forming

ASTM A106B seamless pipes are mainly formed

using two methods: hot rolling and cold drawing.

The hot rolling process first heats the

steel billet to approximately 1200℃, then pierces the

solid billet into a hollow tube using a piercing mill, and finally rolls it to

the required dimensions using a continuous rolling mill. During this process,

the steel billet recrystallizes at high temperatures, refining the grains and resulting

in a final product with higher strength and toughness.

The cold-drawing process involves

repeatedly drawing the steel tube at room temperature using a die, resulting in

more precise dimensional tolerances and a smoother surface finish. This is

particularly suitable for applications requiring strict dimensional accuracy.

ASTM A106 Gr B Seamless Pipe Quality

Control

1. Dimensional Inspection

Use calipers, thickness gauges, and other

tools to measure dimensions such as outer diameter and wall thickness. Ovality

should be controlled within the standard allowable range. Length deviations

must conform to the drawing requirements.

2. Non-destructive Testing

Radiographic testing is suitable for

detecting internal defects in welds. Ultrasonic testing can be used to detect

delamination in the base material. Magnetic particle testing mainly checks for

surface cracks, while penetrant testing is suitable for non-ferromagnetic

materials. The testing ratio should be determined based on the usage

conditions.

3. Pressure Testing

The hydrostatic test pressure is generally

1.5 times the design pressure, and the pressure holding time should be no less

than 10 minutes. During the test, check for leaks, and promptly remove any

accumulated water after the test.

ASTM A106 Gr B Equivalent Material

ASTM A106 Grade B is equivalent to the

following materials in terms of chemical composition and mechanical properties:

|

Execution

|

Standard

|

Material

|

European Standard

|

Material

|

|

Seamless

|

API 5L

|

Grade X52

|

EN 10208-2

|

L360NB

|

|

Seamless

|

ASTM A333

|

GRADE 6

|

EN 10216-4

|

P265NL

|

|

Welded

|

API 5L

|

Grade B

|

EN 10208-2

|

L245NB

|

|

Seamless

|

ASTM A106

|

GRADE B

|

EN 10216-2

|

P265GH

|

|

Seamless

|

API 5L

|

Grade B

|

EN 10208-2

|

L245NB

|

|

Welded

|

API 5L

|

Grade X52

|

EN 10208-2

|

L360NB

|

Applications of ASTM A106 Gr B Seamless Pipe

1. Oil and Gas Industry

Used for transporting fluids such as crude oil and natural gas. Its seamless structure reduces the risk of leakage and is suitable for long-distance pipeline systems.

2. Chemical Industry

In chemical plants, A106B seamless pipe is often used to handle corrosive media or high-temperature fluids, but material limitations must be considered to avoid premature damage.

3. Power Industry

As boiler piping or heat exchanger components, A106B seamless pipe can withstand high pressure and high temperature conditions, ensuring safe system operation.

4. Building and Infrastructure

In large buildings, A106B seamless pipe can be used as structural support or for transporting resources such as water and electricity.

FAQ

1. Is ASTM A106 Gr B suitable for cryogenic

environments?

No.

ASTM A106 Gr B is not cryogenic steel and

may experience brittle fracture at low temperatures.

2. What is the difference between ASTM A106

Gr B and API 5L Grade B?

ASTM A106 Grade B is suitable for

high-temperature, high-pressure pipelines. API 5L Grade B is suitable for

pipelines transporting goods at normal temperatures.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.