The density of carbon

steel pipe is typically 7.85 g/cm³. Carbon

steel is mainly composed of iron (Fe) and carbon (C), and its density is close

to that of pure iron (7.87 g/cm³), but it fluctuates

slightly due to differences in carbon content and other trace elements. This

article will provide an authoritative and engineering-based analysis of the

density of carbon steel pipe based on internationally accepted engineering

experience and mainstream standards (ASTM / API / EN / GB).

What is the Standard Density of Carbon

Steel Pipe?

The general engineering density of carbon

steel pipe is 7.85 g/cm³ (i.e., 7850 kg/m³).

This value is widely used in engineering

calculations and designs worldwide. It is not derived from a single standard

clause, but rather is a summary value based on the physical properties of the

iron-carbon alloy system. It is used by default in the following international

and industry standards:

ASTM A36 / ASTM

A106 / ASTM A53

API 5L / API 5CT

EN 10216 / EN 10219

GB/T 8162 / GB/T 3091

Density Differences Between Different Carbon

Steel Grades

Carbon steel is mainly composed of iron

(Fe) and carbon (C), with a carbon content typically ranging from 0.05% to 1.0%

(engineering steel). The crystal structure of iron (body-centered cubic or

face-centered cubic) and interstitial solid solution of carbon atoms are key

factors determining density.

The density differences in carbon steel

mainly stem from its composition and heat treatment processes, but the

variation range is extremely small. In engineering calculations, a uniform

value of 7.85 g/cm³ is typically used.

|

Carbon Steel Type

|

Typical Grade

|

Density (g/cm³)

|

Engineering Description

|

|

Mild Steel

|

Q235 / ASTM A36

|

≈ 7.85

|

Most commonly used, uniform value used in

engineering

|

|

Medium Carbon Steel

|

45# / C45

|

≈ 7.84–7.85

|

Theoretically slightly lower, practically

negligible

|

|

Pipeline Steel

|

API 5L X52–X70

|

≈ 7.85

|

Different strengths, consistent density

|

Density is a key parameter in material

selection, directly affecting weight calculations, transportation costs, and

structural design. For example, in building frames, density, combined with pipe

diameter and wall thickness, can accurately estimate material usage.

Does the Type of Carbon Steel Pipe

Affect Density

Manufactured through hot rolling or cold

drawing processes, with uniform density, commonly used in high-pressure

environments (such as oil pipelines).

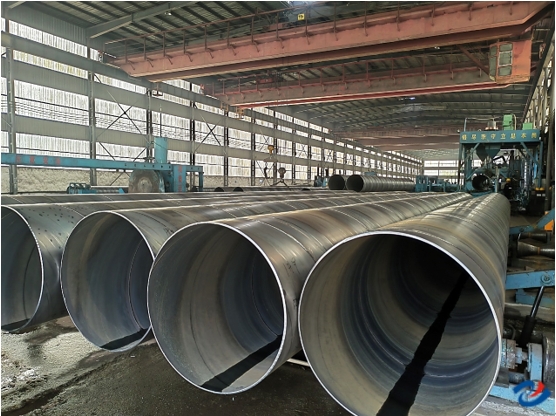

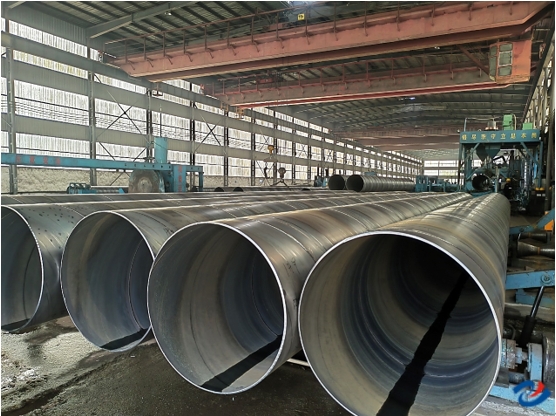

2. Welded Steel Pipe

Made from rolled and welded steel plates,

the density in the weld area may be slightly lower (approximately 7.8 g/cm³), but the overall density is still close to the standard value.

3. Galvanized Steel Pipe

The galvanized layer adds weight, but the

base material density remains unchanged. The coating weight needs to be

calculated separately (zinc density is 7.14 g/cm³).

Factors Affecting the Density of Carbon

Steel Pipes

The density of carbon steel decreases with

increasing temperature. For example, the density is 7.85 g/cm³ at room temperature (20℃), but may drop to

7.80 g/cm³ when heated to 500℃.

2. Manufacturing Process

The manufacturing process also has a

certain impact on the density of carbon steel pipes. For example, different

processing methods such as cold drawing and hot rolling may lead to changes in

the internal structure and density of the pipe.

3. Steel Grade

The density of carbon steel pipes is also

related to the steel grade. For example, low-carbon steel, medium-carbon steel,

and high-carbon steel have different densities. Generally, the higher the

carbon content of the steel grade, the lower its density may be.

How to Measure the Density of Carbon

Steel Pipes

Density Calculation Formula (kg/m): Outer

Diameter (mm) - Wall Thickness (mm) × Wall Thickness

(mm) × 0.0248

For example: (88.9 mm - 3.05 mm) × 3.05 mm × 0.0248 = 6.49 kg/m.

Why is Density Important for Carbon

Steel Pipes?

1. Weight Calculation

Density is a key parameter for estimating

pipe weight.

For example, the weight of a carbon steel

pipe with an outer diameter of 114 mm, a wall thickness of 6 mm, and a length

of 6 meters can be calculated using the formula (outer diameter - wall

thickness) × wall thickness × length × density × π.

2. Pressure Design

High-density materials generally have

better mechanical strength, but this needs to be evaluated in conjunction with

parameters such as yield strength.

For example, different grades of pipeline

steel in the API 5L standard have similar densities, but their tensile

strengths differ significantly.

3. Cost Control

Density directly affects transportation and

installation costs; for example, pipelines are often charged by weight in

maritime transport.

Comparison of Carbon Steel Density with

Other Materials

|

Material Type

|

Density (g/cm³)

|

Properties

|

|

Carbon Steel (Q235)

|

7.85

|

Economical and durable, widely used in

low-pressure pipelines

|

|

Stainless Steel (304)

|

7.93

|

Corrosion resistant, but more expensive

|

|

Aluminum Alloy (6061)

|

2.70

|

Lightweight, suitable for aviation or

mobile equipment

|

|

PVC Plastic

|

1.38

|

Insulating and corrosion resistant, but

poor temperature resistance

|

Application Considerations

1. Temperature Influence

In high-temperature conditions (such as

boiler pipelines), it is necessary to refer to standards such as ASME B31.1 to

consider the indirect impact of thermal expansion on density.

2. Standard Differences

Different national/industry standards may

have slight requirements for the composition of carbon steel, but the density

values are usually consistent. For example, the Japanese standard JIS G3101

SS400 has the same density as the Chinese standard Q235.

FAQ

1. Does the density of carbon steel pipes

vary with specifications?

No.

Density is an inherent property of the

material and is independent of the size of the carbon steel pipe. However,

different wall thicknesses or outer diameters will affect the total weight.

2. How to verify the accuracy of density

data?

Verification can be done through: Material

Certificate (MTC); International Standard References (ASTM/EN/GB); Engineering

manuals or steel mill technical data.

3. Are the densities of carbon steel pipes

of different steel grades the same?

They are basically the same.

Whether it is Q235, ASTM A36, ASTM A106, or

API 5L X42–X70, their density is treated as 7.85 g/cm³ in engineering calculations.

The main differences between different

steel grades lie in yield strength, tensile strength, and chemical composition

control, not density.

4. Does the density of carbon steel pipes

need to be corrected for high-temperature environments?

In conventional piping and structural

applications, no correction is required.

However, in boilers, high-temperature

steam, or thermal systems, design standards such as ASME and EN should be

consulted, taking into account thermal expansion and strength reduction

factors, rather than just density changes.

Read more: Carbon Steel Pipe Material Grade or Roughness of Carbon Steel Pipe

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.