The roughness of steel pipes is an important indicator for measuring the microscopic unevenness of the pipe surface, directly affecting fluid transport efficiency, corrosion resistance, scaling tendency, and service life. The common inner wall roughness of carbon steel pipes is generally in the range of Ra 1.6–6.3 μm; this value can vary depending on the processing method, surface treatment, and service conditions.

Concept and Measurement Methods of Carbon Steel Pipe Roughness

Carbon steel pipe roughness refers to the irregularity and density of the pipe wall surface.

In industrial applications, roughness affects:

Fluid friction coefficient;

Transportation efficiency and energy consumption;

Inner wall scaling rate;

Pipe corrosion resistance.

Common measurement methods include:

Contact roughness tester (stylus type): High accuracy, most widely used in engineering.

Non-contact white light interferometer, laser scanning: Used for high-precision measurement.

Inspection standards: Commonly refer to ISO 4287/4288 and GB/T 1031-2009.

Common Carbon Steel Pipe Roughness

1. Ra Value

The Ra value is the contour area value of the geometric mean line on the surface of the pipe. It is expressed in microns (μm) as a non-directional comprehensive surface roughness index.

It is calculated by taking the average distance difference between all points on the surface of the pipe and its corresponding datum plane, which is generally between 1.6-6.3μm.

2. Rz Value

The Rz value is the average dispersion between the peaks and valleys of any five adjacent sections along the length of the pipe, expressed in microns.

It is measured along the length of the pipe and reflects more of the longitudinal direction of the pipe surface. Uneven conditions. The Rz value of carbon steel pipe is generally between 10-50μm.

3. Rmax Value

The Rmax value refers to the groove depth between the largest peak value and the smallest valley value on any short length of the pipe surface.

It only considers the maximum irregularity between surfaces in local areas. It is a non-directional indicator. It is usually used to measure the size of protruding defects such as surface depressions, bulges, and burrs, generally between 20-200μm.

Comparison of Typical Carbon Steel Pipe Roughness

Values

|

Material / Process

|

Typical Ra Roughness (μm)

|

Characteristics

|

|

Cold-drawn carbon steel pipe

|

1.6–3.2

|

Smooth surface, high dimensional accuracy

|

|

Hot-rolled carbon steel pipe

|

3.2–12.5

|

Significant differences between different

production lines

|

The Impact of Roughness on Carbon Steel

Pipe Performance

The roughness of carbon steel pipes has a

crucial impact on the operating conditions and performance of fluids in the

pipeline.

1. If the pipe surface is too rough, it

will increase resistance to fluid flow, leading to increased turbulence and

friction. This will not only reduce pipeline transportation efficiency but also

affect the stability of fluid flow.

2. If the pipe surface is too smooth, it

may also lead to insufficient shear force, which will also affect the fluid's

state and flow properties. Therefore, properly controlling the roughness of

carbon steel pipes is key to ensuring the normal operation of pipeline fluids.

Methods for Optimizing Carbon Steel Pipe

Roughness

To optimize the roughness of carbon steel

pipes, a series of effective measures can be taken. For example, galvanizing,

polishing, internal coating, and internal lining can be used to improve the

surface finish of the pipe. These measures not only improve the compressive

strength and corrosion resistance of the pipe, but also effectively reduce the

surface roughness of the pipe, reducing the accumulation of scale, sediment,

and bacteria. This ensures the stability and safety of pipeline operation and

extends the service life of the pipe.

1. Surface Finishing

Inner wall polishing/grinding (Ra 0.4–1.6 μm)

Precision cold drawing process

Roll forming strengthening

2. Corrosion Protection and Coating

Inner epoxy coating (FBE)

Inner lining PE, PP, rubber lining

Hot-dip galvanizing

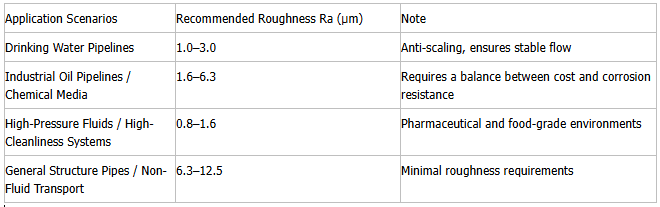

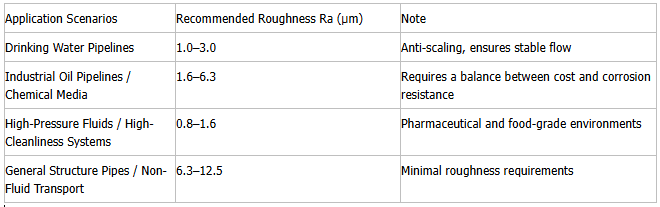

Carbon Steel Pipe Roughness Reference Values

Conclusion

The roughness of carbon steel pipe is an important indicator for evaluating the surface quality of pipes. In general, the smoother the pipe surface and the smaller the roughness, the longer its service life.

Read more: Carbon

Steel Pipe Roughness Coefficient Calculation or Thermal Conductivity of Carbon Steel Pipe

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.