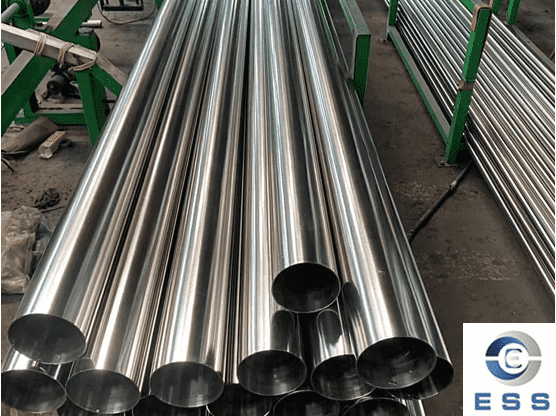

Straightness of precision

tubes refers to the degree of deviation of the tube's axis from an

ideal straight line along its entire length. It is usually expressed as the

ratio of the maximum bending value to the tube length, commonly measured in

mm/m or mm/total length. Straightness not only affects subsequent processing

performance but also directly relates to assembly accuracy, equipment lifespan,

and system operational stability, especially in demanding fields such as

hydraulics, automotive, and machinery manufacturing.

What is the Straightness of Precision

Tube

The core dimensional accuracy indicators of

precision tubes include outer diameter accuracy, wall thickness accuracy,

roundness, straightness, and concentricity. The straightness of a precision

tube refers to the degree of deviation of the tube's centerline along its

length. The quality of straightness affects the processing, installation, and

use of precision tubes.

Straightness vs. Roundness vs.

Concentricity of Precision Tubes

Straightness controls the tube's axis,

reflecting whether the entire steel tube is bent, affecting assembly,

processing, and automatic feeding.

Roundness controls a single cross-section,

reflecting whether the cross-section is close to a perfect circle, affecting

sealing performance and fit accuracy.

Concentricity control measures the inner

and outer circular axes, reflecting the uniformity of wall thickness and

affecting pressure resistance and lifespan.

Standards of Precision Tubes

Straightness

Common standards for the straightness of

precision tubes include EN

10305 standard , ASTM A519-06 standard, and JIS G3445 standard.

|

Standard

|

Standard Name

|

Straightness Description

|

|

GB/T 3639-2009

|

Cold-drawn or cold-rolled precision

seamless steel tubes

|

Provides straightness control

requirements, usually expressed in mm/m.

|

|

EN 10305 Series

|

European precision steel tube standards

|

Provides explicit geometric tolerance

requirements for cold-drawn

precision tubes.

|

|

ASTM A519

|

Seamless machine tubes

|

No mandatory uniform values; mostly based

on supply and demand agreements.

|

|

JIS G3445

|

Carbon

steel pipes for mechanical structures

|

Provides requirements for dimensional

quality and straightness.

|

|

ISO 3304

|

Cold-drawn precision tubes

|

Specify outer diameter, wall thickness,

and straightness grade.

|

Precision Tubes Straightness Tolerance

The straightness tolerance of precision

tubes refers to the maximum permissible deviation between the axis of the steel

tube and an ideal straight line, usually expressed in millimeters per meter

(mm/m). Common tolerance ranges are as follows:

1. Ordinary Precision Tubes

Straightness tolerance is generally

0.5mm/m~1.5mm/m (refer to GB/T 3639-2009 "Cold-drawn or cold-rolled

precision seamless steel tubes").

2. High Precision Steel Tubes

For tubes used in hydraulic cylinders,

tolerances are more stringent, typically requiring 0.3mm/m~0.8mm/m (refer to

ISO 3304 standard).

3. Special Purpose Steel Tubes

For tubes used in aerospace or precision

instruments, tolerances may be lower than 0.2mm/m, depending on customer

requirements.

How to Test the Precision Tube Straightness

1. Straightedge + Dial Indicator Method

(routine factory inspection)

Place the precision tube on a

high-precision straightedge or V-block. Move the dial indicator along the

length of the tube and record the maximum runout value.

Judgment Formula: Maximum runout value ÷ Measurement length (m)

This method is low-cost and simple to

operate, but is significantly affected by human factors and its efficiency is

generally low.

2. Laser Rangefinder Method

This method uses a laser rangefinder to

measure the position of various points on the axis of the steel pipe, and

obtains the straightness result through data analysis.

This method has high accuracy and speed,

and is suitable for rapid inspection in mass production.

3. Wire Pulling Method

Thin wires are fixed at both ends of the

precision pipe, and the straightness is evaluated by observing the deviation

between the wires and the axis of the steel pipe.

This method is simple and easy to

implement, but its accuracy is relatively low. It is only suitable for rough

judgment and is not recommended for final inspection of precision pipes.

Factors Affecting the Straightness of

Precision Pipes

1. Raw Material Selection

The selection of raw materials in precision

pipe production is the basis for straightness control. If the shape, size,

hardness, and chemical composition of the raw materials do not meet the

standard requirements, it will affect the straightness of the pipe.

2. Heat Treatment Technology

The heat treatment technology in the

precision pipe production process also affects the straightness of the pipe.

Tempering or annealing techniques are usually used to improve the straightness

of the pipe. However, improper heat treatment can alter the original

straightness of the tube.

3. Manufacturing Process

Processes such as drawing and precision

rolling in precision tube production also affect the straightness of the tube.

Inappropriate manufacturing processes, substandard equipment, or improper

operation can all negatively impact the straightness of the tube.

How to Improve the Straightness of

Precision Tube

1. Optimize Raw Material Selection

Use high-quality raw materials with stable

quality and uniform internal stress, strictly controlling the chemical

composition and microstructure uniformity to fundamentally improve the

straightness of the precision tube.

2. Improve Processing Technology

Optimize the parameter settings and

operation methods of rolling, drawing, and straightening processes. Reasonably

design the cold drawing deformation amount, configure multi-roll straightening

equipment, and control the rolling and drawing speeds to reduce deformation and

stress concentration during processing.

3. Improve Heat Treatment System

Strictly control parameters such as

temperature, time, and cooling rate during heat treatment, employing

stress-relief annealing to ensure that the precision tube maintains good

straightness after heat treatment.

The Importance of Straightness

Inspection in Precision Tube Production

Straightness inspection is a crucial step

in the production

process of precision tubes. It not only ensures that the quality of the

steel tubes meets standard requirements but also allows for the timely

detection of problems during production, providing a basis for improvement and

optimization.

Through strict control of raw material

quality, optimization of production processes and equipment, strengthening of

testing methods, and implementation of a quality monitoring system, it is

possible to ensure that the straightness of precision tubes meets standard

requirements, providing high-quality raw material guarantees for the

manufacturing of high-precision mechanical parts and transportation.

FAQ

1. What problems will non-compliant

straightness of precision tubes cause?

Out-of-tolerance straightness may lead to:

CNC machining vibration or abnormal tool

wear;

Automatic feeding and cutting equipment

jamming;

Assembly deviations, decreased coaxiality;

Increased costs of finished product scrap

or rework.

Straightness issues are particularly

prominent for long-length precision tubes.

2. Is there a difference in straightness

between cold-drawn and cold-rolled precision tubes?

Cold-rolled precision tubes: Dimensional

stability and straightness are easier to control.

Cold-drawn precision tubes: Straightness is

ensured by subsequent straightening processes.

Whether there is a significant difference

between the two depends on the equipment level and straightening capacity.

Conclusion

The straightness of precision tubes is not

only a geometric indicator, but also a comprehensive reflection of

manufacturing capabilities, process control, and quality systems. Through

strict raw material management, scientific processing techniques, stable heat

treatment systems, and reliable testing methods, the long-term stable operation

of precision seamless steel tubes in high-end applications can be ensured.

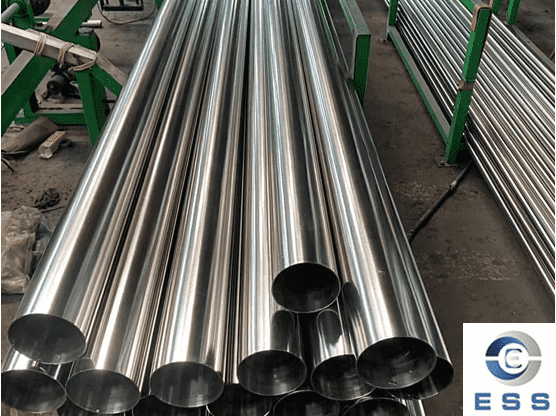

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.