NC50 drill pipe (Numbered Connection 50 Drill Pipe) is an high-performance, wear-resistant

advanced oil drill pipe conforming to API

Spec 5DP standards, used with the NC50 digital connection thread type

(API IF series), and widely applied in medium-deep wells and some deep well oil

and gas drilling operations.

NC50 does not refer to the outer diameter

of the drill pipe, but rather to the connection specification used in the tool

joint. In practical applications, NC50 is most commonly paired with a 5-inch

drill pipe outer diameter to achieve the best balance of strength, torque, and

economy.

API Drilling Tools Joint Thread Type

1. NC26

API Standard Joint Thread Type: NC26=2-3/8"'IF

Tools/Inch: 4

PIN DIA: 60.35mm

2. NC31

API Standard Joint Thread Type: NC31=2-7/8"IF

Tools/Inch: 4

PIN DIA: 71.31mm

3. NC38

API Standard Joint Thread Type: NC38=3-1/2"'IF

Tools/Inch: 4

PIN DIA: 85.06mm

4. NC40

API Standard Joint Thread Type: NC40=4'IF

Tools/Inch: 4

PIN DIA: 98.06mm

5. NC44

API Standard Joint Thread Type: NC44=4'IF

Tools/Inch: 4

PIN DIA: 98.42mm

6. NC46

API Standard Joint Thread Type: NC46=4'IF

Tools/Inch: 4

PIN DIA: 103.73mm

7. NC50

API Standard Joint Thread Type: NC50=4-1/2"'IF

Tools/Inch: 4

PIN DIA: 114.30mm

8. NC56

API Standard Joint Thread Type: NC56

Tools/Inch: 4

PIN DIA: 117.50mm

API Drill Pipe Numbered Connections (NC)

|

Connection Size and Style RSC Type

|

Box OD (in)

|

Pin ID (in)

|

Make-Up Torque (ft-lbs)

|

Torsional Yield (ft-lbs)

|

Pin Tensile Yield (lbs)

|

|

NC 50

|

6 3/8

|

2 3/4

|

30,290

|

50,484 b

|

1,551,700

|

|

3

|

30,290

|

50,484 b

|

1,416,200

|

|

3 1/4

|

30,290

|

50,484 b

|

1,268,900

|

|

3 1/2

|

26,674

|

44,456

|

1,109,900

|

|

3 3/4

|

22,361

|

37,269

|

939,000

|

|

6 1/2

|

2 3/4

|

34,191

|

56,984 b

|

1,551,700

|

|

3

|

34,191

|

56,984 b

|

1,416,200

|

|

3 1/4

|

30,730

|

51,217

|

1,268,900

|

|

3 1/2

|

26,674

|

44,456

|

1,109,900

|

|

3 3/4

|

22,361

|

37,269

|

939,000

|

|

6 5/8

|

2 3/4

|

38,036

|

63,393

|

1,551,700

|

|

3

|

34,520

|

57,534

|

1,416,200

|

|

3 1/4

|

30,730

|

51,217

|

1,268,900

|

|

3 1/2

|

26,674

|

44,456

|

1,109,900

|

|

3 3/4

|

22,361

|

37,269

|

939,000

|

b - Torsional yield values shown in yellow indicate the connection is box weak in torsion.

The torsional yield strength is based on a shear strength of 57.7% of the minimum yield strength

The tensile strength of the tool joint pin is based on 120,000 psi yield and the cross sectional area at the root of the thread 5/8" from the shoulder.

NC50 Drill Pipe Specs and Manufacturing

Process

1. Specification

Pipe Body Material: Seamless

steel pipe;

Common Steel Grades: E-75, X-95, G-105,

S-135;

S-135 steel grade, due to its high yield

strength (≥135 ksi), has become the mainstream choice

for deep wells.

2. Joint Manufacturing

Joints are typically made of AISI 4137 /

4140 / 4145H modified steel;

Quenching and tempering treatment;

Surface phosphating or copper plating

treatment to improve anti-galling and wear resistance.

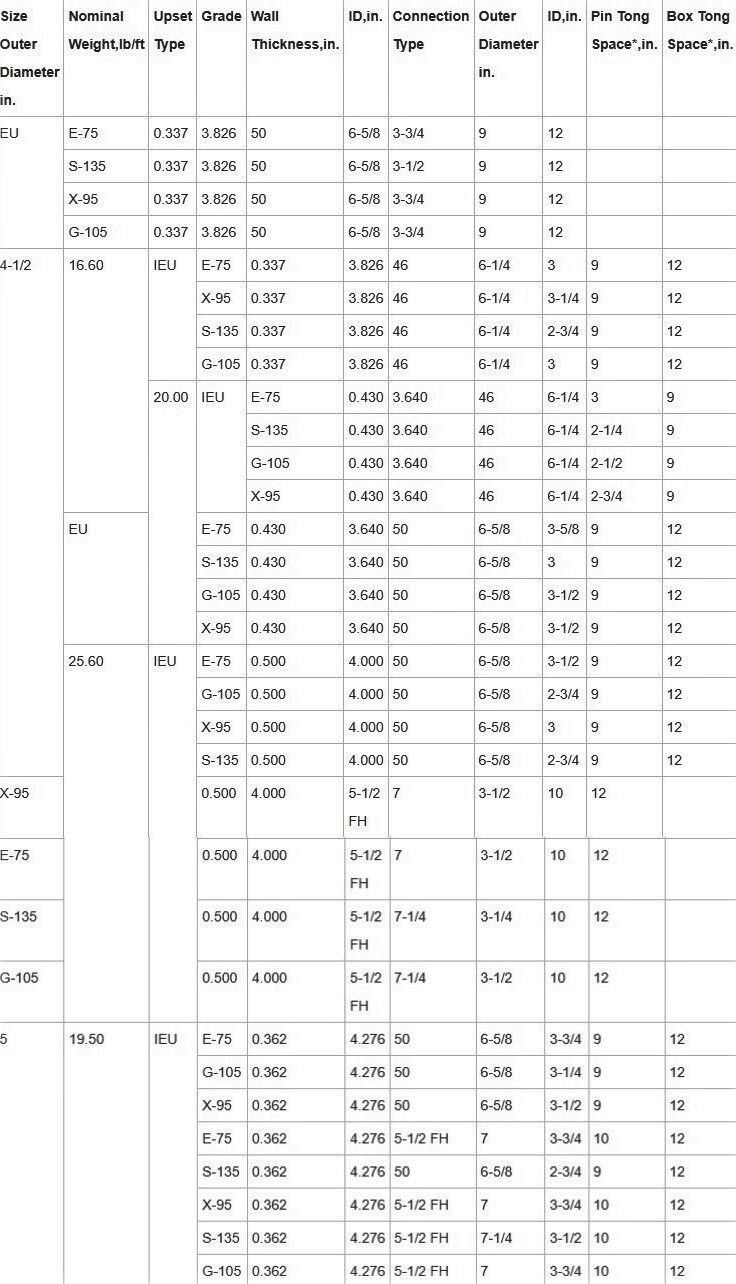

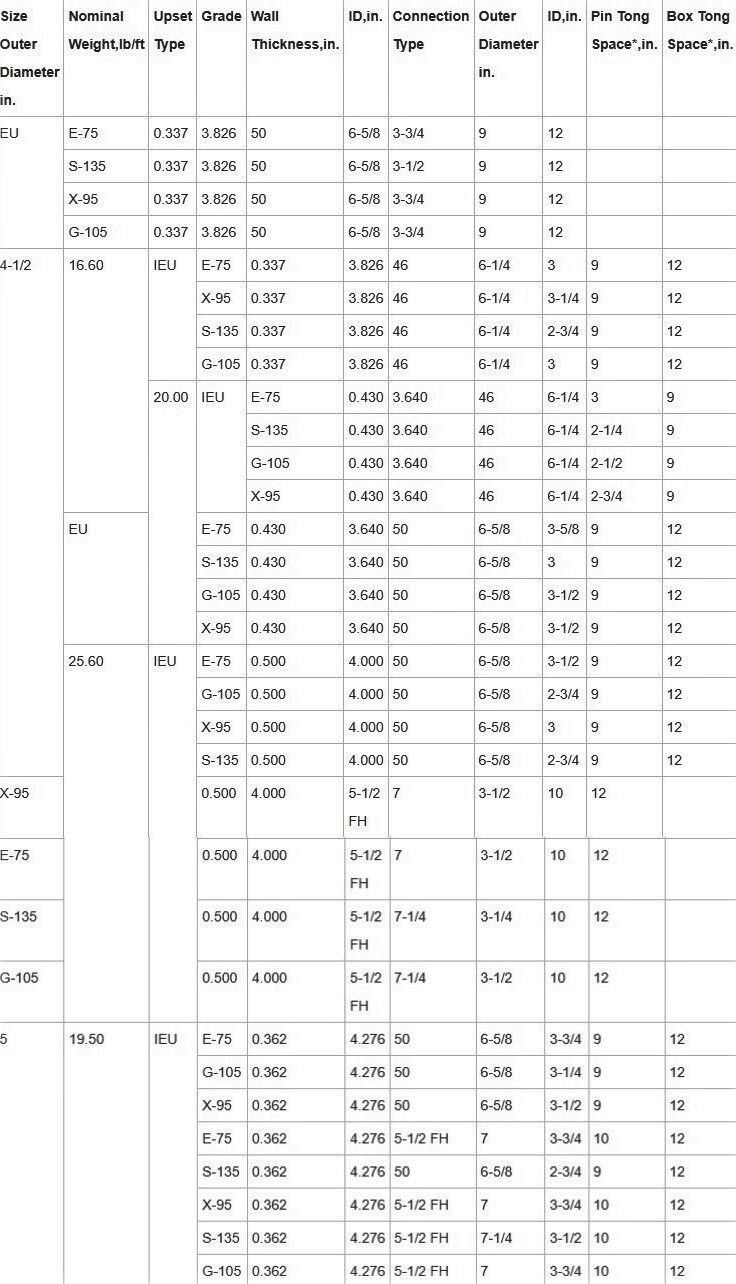

NC50 Drill Pipe Sizes

API 5DP NC50 Drill Pipe Weight Chart

|

Outer

Diameter in inch

|

Connection

|

Grade

|

Range

|

Wall

Thickness in Inch

|

Nominal

Size LBS per inch

|

Adjusted

|

TJ

Outer Diameter in Inch

|

TJ

Inner Diameter in Inch

|

Tube

Inner Diameter in Inch

|

TJ

Yield

|

Minimum

MUT

|

Maximum

MUT

|

Tube

Tensile in Lbs

|

|

5

|

NC50

|

G-105

|

II

|

0.362

|

19.50

|

24.11

|

6 5/8

|

3 1/4

|

4.276

|

51,200

|

25,600

|

30,700

|

436,149

|

|

5

|

NC50

|

S-135

|

III

|

0.362

|

19.50

|

22.39

|

6 5/8

|

2 3/4

|

4.276

|

63,400

|

31,700

|

38,000

|

560,763

|

|

5

|

NC50

|

S-135

|

II

|

0.362

|

19.50

|

24.11

|

6 5/8

|

3 1/4

|

4.276

|

51,200

|

25,600

|

30,700

|

560,763

|

Price List of NC50 API Drill Pipes

|

API 5DP drilling seamless

S135 NC50 4 1/2" /5" drill pipes

|

US $1880-$1900/ Ton

|

|

API 5DP oilfield s135

steel NC50 drill pipes

|

US $198.00-$598.00/ Piece

|

|

NC50 API drilling pipes

|

US $2,000-4,000 / Piece

|

The actual price is greatly affected by

steel grade, length, and testing requirements (UT / MPI / Hardbanding).

NC52 vs. NC50 Drill Pipe

1. Size and Pressure Resistance

The most obvious difference between NC52

and NC50 drill pipe lies in their size design. NC52 typically has an outer

diameter of 5.25 inches, thicker than the 5-inch diameter of NC50.

This difference directly translates to

greater torsional resistance—the upper torque limit of

NC52 is approximately 15% higher than that of NC50.

In terms of wall thickness, NC52 is on

average 0.15 inches thicker than NC50, allowing it to withstand greater

downhole pressures during deep well operations.

2. Thread Type

NC52 uses an improved double-shoulder

thread type, with specially optimized thread angles and sealing surfaces:

Connection Strength: The dual-seal

structure increases tensile strength by 20% compared to the single-shoulder

NC50.

Anti-sticking Design: Copper-plated thread

surface, more wear-resistant than the phosphating treatment of NC50.

Torque Required: Requires 30% more torque

than NC50 to achieve ideal sealing performance.

3. Application

NC50: Suitable for shallow to medium-depth

wells up to 3000 meters, offering excellent cost-effectiveness and low

maintenance costs.

NC52: Specialized for deep wells and

complex formations; its reinforced thread type can withstand severe vibrations.

Mixed Use Note: The two drill pipe types

can be used together via adapters, but torque matching is crucial.

FAQ

1. Is NC50 the drill pipe size or the

thread type?

NC50 is the API Digital Connector

specification, typically used with 5" drill pipe.

2. What international standards does NC50

drill pipe conform to?

NC50 drill pipe generally needs to conform

to the following API standards:

API Spec 5DP – Drill pipe manufacturing standards

API RP 7G / 7G-2 – Drill string design and connector parameters

API Spec 7-1 – Drill string connector materials and heat treatment

Compliant products generally provide API

Monogram and MTC (Material Certificate of Conformity).

3. What materials are typically used for

NC50 drill pipe connectors?

Common connector steels: AISI 4137 / 4140 /

4145H

Quenched and tempered (Q&T)

Surface treatment: Phosphating or copper

plating to prevent seizing and wear

Summary

NC50 drill pipe is a cost-effective

mainstream drilling solution, achieving a good balance between strength,

torque, cost, and maintainability, and is widely compatible with API standards.

The system enjoys high recognition in the global oilfield services market.

Read more: API

Drill Pipe Thread Types or Drill Pipe Weight Chart and Calculation

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.