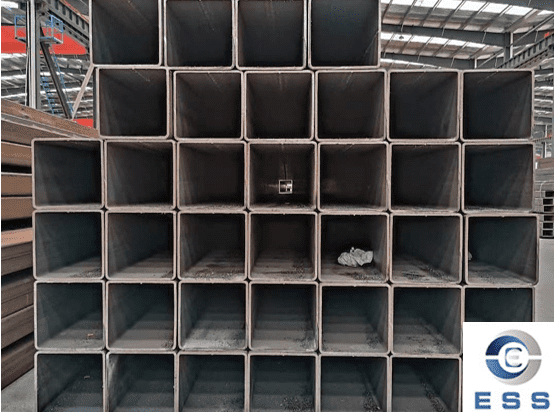

Square tubes (SHS

steel) are a common building material widely

used in construction, machinery manufacturing, and other fields. They are

typically made by bending cold-rolled and hot-rolled steel sheets. Their hollow

structure gives them high strength and compressive strength, while also being

lightweight, easy to process, and available in various specifications.

To facilitate engineering design,

procurement, and processing, it is crucial to accurately understand the methods

for calculating square tube dimensions, weight formulas, cross-sectional area

calculations, and standard specifications. This article provides a complete

guide to square tube dimension calculation.

The basic dimensions of a square tube are

typically composed of the following parameters:

1. Outer Side Length (A)

The side length of the square cross-section

of the tube, such as 50 in 50×50mm.

2. Wall Thickness (t)

The wall thickness of the tube, such as t =

2.0 mm.

3. Inner Side Length (B)

B = A − 2t

4. Length (L)

Commonly 6 m, but can also be customized

upon request.

5. Theoretical Weight

Calculated based on cross-sectional area

and density.

Square Tube Size Classification

Square tubes are a common building

material, frequently used in frame structures, supporting structures, and

interior decoration. Based on size, square tubes can be classified into the

following three types:

1. Small-sized square tubes

Width ≤ 20mm,

Height ≤ 40mm, Thickness ≤ 2.0mm.

2. Medium-sized square tubes

Width 20mm~200mm, Height 40mm~400mm,

Thickness 2.0mm~12.0mm.

3. Large-sized square tubes

Width ≥ 200mm,

Height ≥ 400mm, Thickness ≥ 12.0mm.

Formulas for Calculating the Size of

Square Tubes

1. Calculating formula of square tube inner

side length

The formula for calculating the inner side

length B is:

B = A – 2t

Where,

A = Outer side length

t = Wall thickness

Example:

Outer side length 50mm, wall thickness 2mm

B = 50 − 2×2

= 46 mm

2. Square tube length calculating formula

Standard length:

6m (most commonly used)

12m Processing lengths: 3m, 4.5m, 5.8m, 8m,

etc.

Actual project length calculation method:

L1 = L2 − L3

Where,

L1 = Effective length

L2 = Total length

L3 = Cutting allowance

The cutting allowance is usually 2–5mm (depending on the saw blade type).

The wall thickness of a square tube refers

to its physical thickness, usually expressed in millimeters.

Its calculation method is:

Wall thickness = (Outer diameter - Inner

diameter) ÷ 2

Where both the outer and inner diameters

are in millimeters.

For example:

A square tube with an outer diameter of

60mm and an inner diameter of 50mm has a wall thickness of 5mm.

4. Calculating formula of square tubes cross-sectional

area

The cross-sectional area of a square tube

can be calculated using the following formula:

S = A² − (A − 2t)² = (4At − 4t²)

Where,

A = Outer side length

t = Wall thickness

Example:

50×50×2.0 square tube

S = 4×50×2 − 4×2² = 400 − 16 = 384 mm²

5. Square tube perimeter calculating

formula

The outer perimeter P of a square tube can

be calculated using the following formula:

P = 4A

Where,

A = Outer side length

Example:

A = 100 mm

P = 4×100 = 400 mm

6. Square tube weight calculating

formula

The weight of a square tube refers to the

weight of each tube, usually expressed in kilograms.

Theoretical Weight Formula:

W=S×L×ρ

Where,

ρ = Density (generally 7.85×10⁻⁶ kg/mm³ for carbon steel)

L = Length (mm)

General Formula (in meters):

W (kg)=0.0157×(A−t)×t×L

(Commonly used industry empirical formula)

Example:

100×100×4.0, length 6m

W=0.0157×(100−4)×4×6=22.64 kg

Standard Sizes of Square Tubes

In addition to the sizes calculated using

the above formulas, square tubes also have some common standard sizes.

For example, international standards

include 50×25mm, 80×40mm, and

100×50mm, while Chinese standards include 40×30mm, 70×50mm, and 100×80mm.

When selecting square tubes, you can choose

the appropriate size according to your actual needs.

How to Choose the Appropriate Square

Tube Size?

1. Consider the stress conditions of

square tubes

As a structural material, square tubes need

to withstand certain loads during use.

Therefore, when selecting the size of

square tubes, we need to fully consider their stress conditions, including

static loads, dynamic loads, and impact loads.

Generally speaking, larger square tubes

with stronger load-bearing capacity are suitable for applications with larger

loads, while smaller square tubes are more suitable for light loads or

auxiliary support scenarios.

|

Application Scenarios

|

Recommended Square Tube Size

|

|

Furniture, Lightweight Supports

|

20×20、25×25、30×30

|

|

Indoor Frames

|

40×40、50×50

|

|

Steel Structure Purlins

|

80×80、100×100

|

|

Heavy-Duty Structures

|

≥150×150

|

2. Analyze the usage environment and

requirements

The usage environment of square tubes is

also an important factor to consider when selecting sizes.

For example, square tubes used in humid or

corrosive environments should be selected based on materials and sizes with

good rust and corrosion resistance.

Furthermore, for applications requiring

frequent movement or disassembly, smaller, lighter-weight square tubing may be

more suitable due to its portability.

|

Environment

|

Recommendations

|

|

Outdoor, Humid

|

Galvanized square tubing or wall

thickness ≥ 2.5mm

|

|

High Corrosion

|

Stainless steel square tubing (304/316)

|

|

High Temperature

|

High-strength carbon

steel square tube (Q355, Q460)

|

3. Choosing based on cost budget

While meeting usage requirements, we also

need to consider the cost budget when selecting square tubing size.

Generally, larger square tubing uses more

material, resulting in higher costs.

With a limited budget, we can reduce

reliance on larger square tubing by optimizing structural design and selecting

high-strength materials, thereby effectively controlling costs.

FAQ

1. How is the wall thickness of the square

tubing determined?

The wall thickness is determined by the

design load, mechanical requirements, and the usage environment.

Common wall thickness ranges:

Small square tube: 1.0–2.0mm

Medium square tube: 2.0–4.0mm

Large structural square tube: 4.0–12.0mm

2. What are the standard dimensions for

square tubes?

Common standards include:

GB/T 6728 (China)

EN 10219 (European standard)

ASTM A500 (American standard)

The three standards differ slightly in

their dimensional settings.

3. What are the dimensional differences

between SHS

steel and RHS steel?

Square tube (SHS steel): A = A (square

cross-section)

Rectangular tube

(RHS steel): A ≠ B

(rectangular cross-section)

Rectangular tubes exhibit more pronounced

directional bending resistance.

Square tubes have more uniform overall

compressive strength.

Read more: SHS

steel meaning

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.