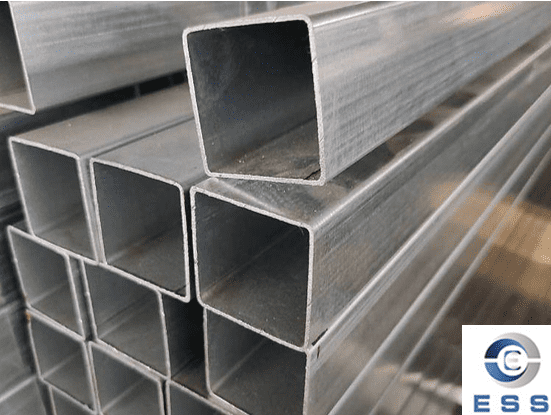

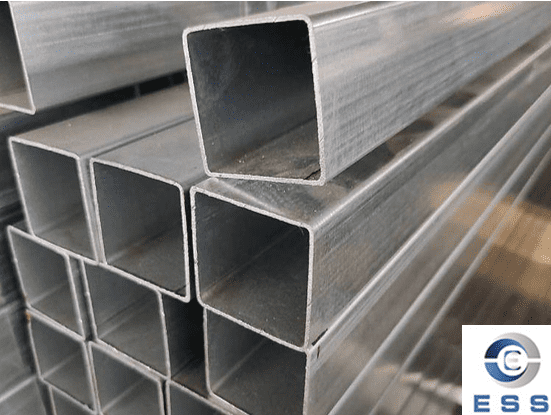

Square tubes (SHS

steel) are cold-formed or hot-rolled steel

profiles with equal width and height and a square cross-section. Common steel

grades include S275, S355, and ASTM A500. SHS steel possesses excellent

load-bearing capacity and torsional strength. These steel profiles are

available in a variety of sizes, thicknesses, and lengths, and are typically

surface-treated with protective coatings such as galvanizing or painting to

enhance their corrosion resistance.

Square Tube Manufacturing Standards

SHS steel is manufactured according to

stringent international standards to ensure quality and performance. Key

standards include:

|

Standard

|

Region/Country

|

Material Type

|

Typical Grade

|

|

ASTM A500

|

USA

|

Cold-formed carbon steel

|

Grade A, B, C

|

|

ASTM A513

|

USA

|

Mechanical tubes

|

Type 1, 2, 5

|

|

EN

10210 / EN

10219

|

Europe

|

Hot-finished / Cold-formed

|

S235, S275, S355

|

|

GB/T 6728-2017

|

China

|

Structural steel

|

Q195, Q235, Q345

|

|

JIS G3466

|

Japan

|

Structural carbon steel

|

STKR400, STKR490

|

|

AS/NZS 1163

|

Australia

|

Cold-formed steel

|

C250, C350, C450

|

These standards specify the dimensional

tolerances, mechanical properties, and chemical composition required for

various structural applications.

Square Tube Specifications

1. Outer Diameter

Commonly available sizes include 10×10, 12×12, 14×14, 16×16, 18×18, 20×20, 25×25, 30×30, and 40×40

mm.

2. Wall Thickness

Common wall thicknesses include 0.6mm,

0.7mm, 0.8mm, 1.0mm, 1.2mm, and 1.5mm. Smaller outer diameter square tubes

generally have thinner walls, while larger diameter square tubes have

relatively thicker walls.

3. Common Lengths

Standard lengths: 6m, 9m, and 12m; custom

cutting services are available.

Square Tube Grades

SHS steel is produced using various steel

grades based on mechanical properties, strength requirements, and application

needs. The following is an overview of some of the most commonly used steel

grades globally:

1. European Standards (EN Grades)

S235 → Standard

structural steel with good weldability and medium strength; used for light to

medium-duty structures.

S275 → Higher

strength than S235; commonly used in general construction and light

manufacturing.

S355 → High-strength structural steel with good toughness and excellent weldability;

ideal for heavy and load-bearing applications.

S420 / S460 → Ultra-high-strength structural steel; used for critical load applications,

bridges, marine, and special engineering projects.

2. ASTM Standards (American Grades)

ASTM A500 A, B, C grades → Cold-formed carbon steel, commonly used in the North American

market.

Square Tube Classification by Size

1. Common Square Tube Sizes (Side Length × Side Length, Unit: mm)

Small Square Tubes: 15×15, 20×20, 25×25, 30×30, 40×40

Medium Square Tubes: 50×50, 60×60, 80×80,

100×100

Large Square Tubes: 120×120, 150×150, 200×200,

300×300, 400×400

2. Square Tube Wall Thickness Range (Unit: mm)

Thin-walled Square Tubes: 1.0~3.0mm

(Decorative, Furniture)

Medium-thick-walled Square Tubes: 3.0~8.0mm

(Building Structures, Machinery)

Thick-walled

Square Tubes: 8.0~18.0mm (Heavy Steel

Structures, Bridges)

Square Tube Size in mm

|

Length * Width * Thickness

|

SHS Steel Weights (6 M)

|

SHS Steel Steel Grades

|

|

15*15*1.50 MM

|

4.21 KG

|

S235 JRH – ST 37

|

|

20*20*1.50 MM

|

5.61 KG

|

S235 JRH – ST 37

|

|

20*20*2.00 MM

|

7.48 KG

|

S235 JRH – ST 37

|

|

20*20*2.50 MM

|

9.50 KG

|

S235 JRH – ST 37

|

|

25*25*1.50 MM

|

7.02 KG

|

S235 JRH – ST 37

|

|

25*25*2.00 MM

|

9.36 KG

|

S235 JRH – ST 37

|

|

25*25*2.50 MM

|

11.80 KG

|

S235 JRH – ST 37

|

|

25*25*3.00 MM

|

12.41 KG

|

S235 JRH – ST 37

|

|

30*30*1.50 MM

|

8.42 KG

|

S235 JRH – ST 37

|

|

30*30*2.00 MM

|

10.56 KG

|

S235 JRH – ST 37

|

|

30*30*2.50 MM

|

14.04 KG

|

S235 JRH – ST 37

|

|

30*30*3.00 MM

|

16.84 KG

|

S235 JRH – ST 37

|

|

40*40*1.50 MM

|

11.23 KG

|

S235 JRH – ST 37

|

|

40*40*2.00 MM

|

14.96 KG

|

S235 JRH – ST 37

|

|

40*40*2.50 MM

|

18.72 KG

|

S235 JRH – ST 37

|

|

40*40*3.00 MM

|

22.46 KG

|

S235 JRH – ST 37

|

|

40*40*4.00 MM

|

29.95 KG

|

S235 JRH – ST 37

|

|

40*40*5.00 MM

|

27.07 KG

|

S235 JRH – ST 37

|

|

50*50*1.50 MM

|

14.04 KG

|

S235 JRH – ST 37

|

|

50*50*2.00 MM

|

18.72 KG

|

S235 JRH – ST 37

|

|

50*50*2.50 MM

|

23.40 KG

|

S235 JRH – ST 37

|

|

50*50*3.00 MM

|

28.08 KG

|

S235 JRH – ST 37

|

|

50*50*4.00 MM

|

37.44 KG

|

S235 JRH – ST 37

|

|

50*50*5.00 MM

|

46.80 KG

|

S235 JRH – ST 37

|

|

60*60*1.50 MM

|

16.84 KG

|

S235 JRH – ST 37

|

|

60*60*2.00 MM

|

22.46 KG

|

S235 JRH – ST 37

|

|

60*60*2.50 MM

|

28.08 KG

|

S235 JRH – ST 37

|

|

60*60*3.00 MM

|

33.69 KG

|

S235 JRH – ST 37

|

|

60*60*4.00 MM

|

44.92 KG

|

S235 JRH – ST 37

|

|

60*60*5.00 MM

|

56.16 KG

|

S235 JRH – ST 37

|

|

70*70*1.50 MM

|

19.65 KG

|

S235 JRH – ST 37

|

|

70*70*2.00 MM

|

26.20 KG

|

S235 JRH – ST 37

|

|

70*70*2.50 MM

|

32.76 KG

|

S235 JRH – ST 37

|

|

70*70*3.00 MM

|

39.31 KG

|

S235 JRH – ST 37

|

|

70*70*4.00 MM

|

52.41 KG

|

S235 JRH – ST 37

|

|

70*70*5.00 MM

|

65.52 KG

|

S235 JRH – ST 37

|

|

80*80*2.00 MM

|

29.95 KG

|

S235 JRH – ST 37

|

|

80*80*2.50 MM

|

37.44 KG

|

S235 JRH – ST 37

|

|

80*80*3.00 MM

|

44.92 KG

|

S235 JRH – ST 37

|

|

80*80*4.00 MM

|

59.90 KG

|

S235 JRH – ST 37

|

|

80*80*5.00 MM

|

74.88 KG

|

S235 JRH – ST 37

|

|

80*80*6.00 MM

|

83.46 KG

|

S235 JRH – ST 37

|

|

90*90*2.00 MM

|

33.69 KG

|

S235 JRH – ST 37

|

|

90*90*2.50 MM

|

42.12 KG

|

S235 JRH – ST 37

|

|

90*90*3.00 MM

|

50.54 KG

|

S235 JRH – ST 37

|

|

90*90*4.00 MM

|

67.39 KG

|

S235 JRH – ST 37

|

|

90*90*5.00 MM

|

84.24 KG

|

S235 JRH – ST 37

|

|

90*90*6.00 MM

|

94.73 KG

|

S235 JRH – ST 37

|

|

100*100*2.00 MM

|

37.44 KG

|

S235 JRH – ST 37

|

|

100*100*2.50 MM

|

46.80 KG

|

S235 JRH – ST 37

|

|

100*100*3.00 MM

|

56.16 KG

|

S235 JRH – ST 37

|

|

100*100*4.00 MM

|

74.88 KG

|

S235 JRH – ST 37

|

|

100*100*5.00 MM

|

93.60 KG

|

S235 JRH – ST 37

|

|

100*100*6.00 MM

|

106.01 KG

|

S235 JRH – ST 37

|

|

100*100*8.00 MM

|

138.04 KG

|

S235 JRH – ST 37

|

|

110*110*3.00 MM

|

60.34 KG

|

S235 JRH – ST 37

|

|

110*110*4.00 MM

|

79.70 KG

|

S235 JRH – ST 37

|

|

110*110*5.00 MM

|

98.68 KG

|

S235 JRH – ST 37

|

|

110*110*6.00 MM

|

117.29 KG

|

S235 JRH – ST 37

|

|

110*110*8.00 MM

|

153.38 KG

|

S235 JRH – ST 37

|

|

120*120*3.00 MM

|

67.39 KG

|

S235 JRH – ST 37

|

|

120*120*4.00 MM

|

89.95 KG

|

S235 JRH – ST 37

|

|

120*120*5.00 MM

|

112.32 KG

|

S235 JRH – ST 37

|

|

120*120*6.00 MM

|

128.57 KG

|

S235 JRH – ST 37

|

|

120*120*8.00 MM

|

168.42 KG

|

S235 JRH – ST 37

|

|

140*140*4.00 MM

|

102.25 KG

|

S235 JRH – ST 37

|

|

140*140*5.00 MM

|

126.88 KG

|

S235 JRH – ST 37

|

|

140*140*6.00 MM

|

151.12 KG

|

S235 JRH – ST 37

|

|

140*140*8.00 MM

|

198.49 KG

|

S235 JRH – ST 37

|

|

150*150*3.00 MM

|

84.24 KG

|

S235 JRH – ST 37

|

|

150*150*4.00 MM

|

112.32 KG

|

S235 JRH – ST 37

|

|

150*150*5.00 MM

|

140.40 KG

|

S235 JRH – ST 37

|

|

150*150*6.00 MM

|

162.40 KG

|

S235 JRH – ST 37

|

|

150*150*8.00 MM

|

213.53 KG

|

S235 JRH – ST 37

|

|

200*200*4.00 MM

|

147.36 KG

|

S235 JRH – ST 37

|

|

200*200*5.00 MM

|

183.26 KG

|

S235 JRH – ST 37

|

|

200*200*6.00 MM

|

218.79 KG

|

S235 JRH – ST 37

|

|

200*200*8.00 MM

|

288.71 KG

|

S235 JRH – ST 37

|

|

200*200*10.00 MM

|

357.13 KG

|

S235 JRH – ST 37

|

|

250*250*5.00 MM

|

234.00 KG

|

S235 JRH – ST 37

|

|

250*250*6.00 MM

|

275.18 KG

|

S235 JRH – ST 37

|

|

250*250*8.00 MM

|

363.90 KG

|

S235 JRH – ST 37

|

|

250*250*10.00 MM

|

451.11 KG

|

S235 JRH – ST 37

|

Application Scenarios of Different

Square Tube Sizes

1. 10×10, 12×12, 15×15, and 20×20

square tubes are suitable for light-duty structures, such as furniture, display

racks, and billboards.

2. 25×25, 30×30, and 40×40 square tubes are suitable for

light and medium-duty structures, such as doors and windows, stair railings,

and fences.

3. 50×50, 60×60, 70×70, and 80×80

square tubes are suitable for medium and large-duty structures, such as

building frames, large machinery supports, and viaducts.

4. 100×100 square

tubes are suitable for large-duty structures, such as long-span buildings and

highway bridges.

How to Choose the Appropriate Square

Tube Size and Thickness

1. Load-Bearing Requirements

Heavy-duty structures (bridges, warehouses) → ≥ 6 mm wall thickness.

Light-duty furniture or decorations → 1-2 mm wall thickness.

2. Length Requirements

Common lengths: 6m, 9m, 12m.

Custom cutting services are available upon

request.

3. Material Grades

General types: Q235, S235.

High-strength applications: Q345, S355, or

ASTM A500 C grade.

4. Corrosion Resistance

Outdoor projects → Galvanized or powder coated.

Indoor → Black

steel or painted finish.

Select the appropriate grade for welding

and forming.

FAQ

1. What are the Standard Sizes for Square

Tubes?

Common side lengths range from 10×10 mm to 400×400 mm, with lengths typically

6m, 9m, or 12m.

2. How Thick are 12 Gauge Square Tubes?

The wall thickness of 12 gauge square tubes

is approximately 2.77 mm (US 12 gauge steel pipe thickness standard).

Read more: Square tube VS. Rectangular tube or SHS

steel meaning

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.