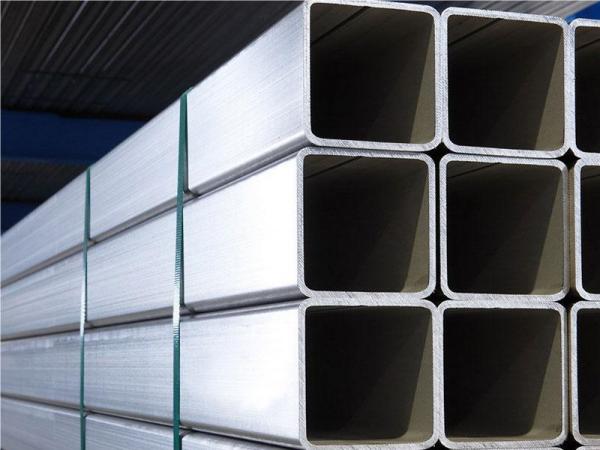

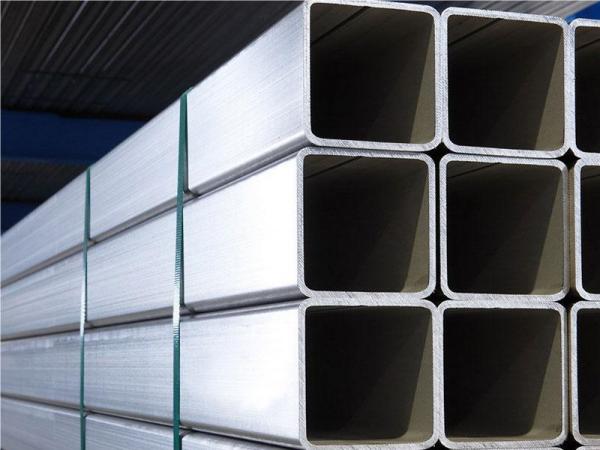

The acronym "SHS" stands for square tube,

a type of metal fabrication primarily used in steel structures. SHS steel is

made from flat steel plates which are then welded together to form hollow

shells or tubes. It is an extremely versatile and cost-effective product

suitable for a wide range of applications in residential, commercial and

industrial buildings; framing; cladding; lintels; and balconies, to name a few.

In general, it can be used in almost any application that requires strength and

durability.

Basics of Steel

To better understand SHS steel, we must first

review some basic facts about steel. Steel has been the material of choice for

centuries because of its strength, durability, recyclability and

cost-effectiveness.

Steel is alloyed iron with a small amount

of carbon added, usually up to 2%. Therefore, it has greater strength and

resistance than pure iron. Steel comes in many grades and shapes, each designed

for a specific purpose.

These products are pieces of cold-rolled steel that are formed into a hollow, tubular section. They get the names of box section and hollow section due to the fact that at the edges, there is a gaping hollow edge going throughout the whole steel bar.

Steel hollow sections are categorised into three primary shapes. Each of these sections has its own attributes, benefits and specific uses.

The main types of steel tube are:

Square Hollow Section (SHS)

Rectangular Hollow Section (RHS)

Circular Hollow Section (CHS)

Before we explore the common uses for these steel sections, it’s important to understand exactly what separates these sections, other than their shape.

SHS Steel Meaning

Steel is one of the most widely used

materials in modern construction, so it is often abbreviated in technical

terms. The acronym SHS steel refers to a specific type of steel called

"square hollow section". Structural hollow sections are steel members

designed for structural framing.

This type of steel is usually made from

hot-rolled and cold-rolled steel plates that are cut, welded and formed into

hollow cylinders or tubes. These tubes are then further divided into smaller

components that can be assembled into complex frames or structures.

SHS Steel Features

1. High strength and stability

The advantage of SHS steel over other

alloys is its ability to be formed into various shapes and to withstand large

loads without buckling or bending. This makes the hollow profile very stable

and reliable.

2. Corrosion resistant

Since it is made of hot-rolled and

cold-rolled steel sheets, SHS steel is highly corrosion-resistant, so it is less

prone to rust and deterioration over time.

SHS steel is available in different grades, some

of which are heat treated for strength and corrosion resistance. The most

commonly used grades in construction are S355 and S235.

3. Flexible processing

Since SHS steel are hollow and can be of

different sizes and dimensions, they can be easily constructed into complex

shapes. This makes them ideal for a range of architectural and engineering

applications such as: curved beams, columns and columns, spandrels, arch spans,

balconies, stairs, window frames, door frames, box girders and many more.

SHS steel is made from a steel strip that is

passed through a series of rolls to form it into the desired shape. The strips

are then welded together to form the desired hollow cross-sectional shape. This

process produces a high strength-to-weight ratio while reducing material waste.

4. Excellent thermal performance

SHS steel also has excellent thermal properties.

This means it retains heat, which makes it ideal for load-bearing applications

in climates that experience temperature extremes. In some cases, SHS steel can

also serve as an insulating medium, helping to reduce energy consumption.

5. Bonding properties

Due to its strong bonding properties, SHS

steel is known for its high level of safety and security. This makes it ideal

for protecting structures in hazardous environments such as mass transit,

petrochemical plants and nuclear power plants.

6. Economical, efficient and

environmentally friendly

Economically, SHS steel is very cost-effective as

it is a cost-effective solution compared to traditional methods such as steel

girders. Its light weight means that less material is required in construction,

reducing costs.

In addition, SHS's production process

enables large-scale production, which saves more costs for customers.

In terms of environmental benefits, SHS steel is

100% recyclable and does not require painting or any other coating before

installation.

SHS Steel Material

1. Carbon Structural Steel

Carbon structural steel is a common material for square tubes due to its high strength, good toughness, ease of processing, and relatively low cost. It is widely used in construction, machinery, and automotive industries.

However, carbon structural steel is prone to corrosion and oxidation, requiring frequent protective treatments.

2. Low-Alloy High-Strength Steel

Low-alloy high-strength steel is a new type of square tube material, widely used due to its high strength, corrosion resistance, heat resistance, and fatigue resistance.

Common steel grades include Q345B and 16Mn, mainly used in bridges, ships, and pipelines. ASTM A500 is a commonly used standard for this type of steel.

3. Stainless Steel

Stainless steel is a material made of chromium and nickel, possessing extremely strong corrosion resistance.

Due to its rust-free, corrosion-free, and non-deformable properties, stainless steel is often used in industries with high requirements for hygiene, high temperature resistance, and corrosion resistance, such as construction, medical, and food processing.

4. Aluminum Alloy

Aluminum alloy square tubes are lightweight, high-strength, and corrosion-resistant, making them widely used in various fields.

They also possess good wear resistance and electrical conductivity, making them popular in light industry and high-end construction.

Most regions, including Australia, Europe,

and Asia, use metric units (millimeters). However, in the U.S. and some parts

of the Middle East, imperial units like inches are still in use. For example:

2” x 2” SHS = ~50mm x 50mm

4” x 4” SHS = ~100mm x 100mm

Always confirm units when ordering steel

internationally to avoid mismatches.

SHS steel is manufactured in a wide range

of standard sizes to suit different structural and architectural needs. While

exact availability may vary by country and supplier, common sizes in

millimeters include:

|

Outside Width (mm)

|

Wall Thickness (mm)

|

Common Uses

|

|

25 x 25

|

1.6 – 2.5

|

Fencing, furniture, light frames

|

|

50 x 50

|

2.0 – 3.0

|

Gates, posts, small structures

|

|

75 x 75

|

2.5 – 4.0

|

Residential frames, support beams

|

|

100 x 100

|

3.0 – 5.0

|

Commercial structures, columns

|

|

150 x 150

|

4.0 – 6.0

|

Industrial beams, large load supports

|

|

200 x 200

|

6.0 – 10.0

|

Heavy-duty columns, warehouse frameworks

|

|

250 x 250

|

6.0 – 16.0

|

Infrastructure, high-load structures

|

SHS Steel Production Process

The production process behind SHS steel is

both precise and carefully controlled to ensure structural reliability,

dimensional accuracy, and surface quality. Whether used in residential fencing

or large industrial frameworks, every piece goes through a series of

standardized steps designed to meet strict performance requirements.

1. Raw Steel Preparation

Hot rolled coil steel is used as the

starting material.

2. Cold Forming

The coil is shaped into a square form

through roll forming processes.

3. Welding (for ERW SHS Steel)

Edges are joined using Electric Resistance

Welding.

4. Sizing and Straightening

The square tube is sized to precise dimensions.

5. Surface Finishing

SHS steel can be hot-dip galvanized,

powder-coated, or left as raw steel depending on the desired finish.

6. Cutting and Packaging

Final products are cut to length and

bundled for delivery.

SHS Steel Application

Hollow profiles vary in shape and size

according to the purpose and design of the structure they support.

In general, SHS steel and profiles are used

anywhere in engineering, architectural, construction and manufacturing

applications where strength and quality are critical factors.

1. Due to its strong physical properties,

SHS steel is an excellent choice for structural engineering such as bridges,

buildings, towers and other tall structures.

2. It's also a popular material choice for

industrial infrastructure like pipes and railings, and residential projects

like decks and porches.

FAQ

SHS (Square Hollow Section) refers to a

square hollow section, while RHS (Rectangular Hollow Section) refers to a

rectangular hollow section.

The main difference between the two lies in

their cross-sectional shape: SHS has equal sides and is suitable for

symmetrical load-bearing structures; RHS has unequal lengths and widths and is

often used in beams or supporting structures to improve load-bearing

efficiency.

2. What is the difference between SHS stee and CHS steel?

CHS (Circular Hollow Section) is a circular

hollow section, while SHS is square.

CHS offers better compression and torsion

resistance and is suitable for structures such as columns, masts, and towers.

SHS, on the other hand, has straight edges

and corners, making it easier to join and weld, making it more suitable for

frames and beam-column structures.

3. What are the commonly used steel

grades for SHS steel?

The most common SHS steel grades include

S235, S275, and S355. Among them, S355 SHS is widely used in construction and

engineering projects due to its high strength, good weldability and corrosion

resistance.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.