How should square tubes be welded?

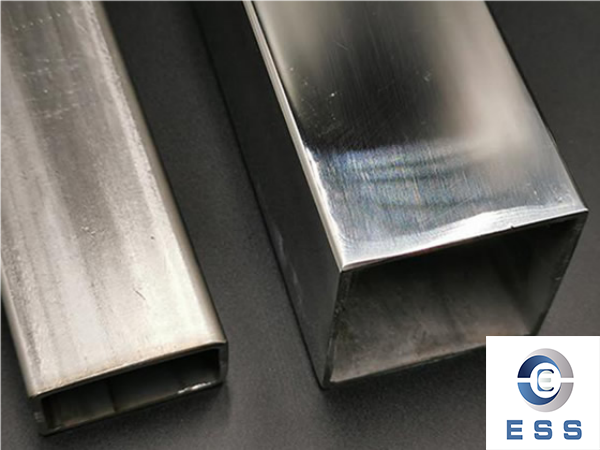

1.What is welded square pipe

Welded square pipes, also known as welded pipes, are square pipes made of steel plates or strips that are curled and welded. Large diameter or thicker welded square pipes are generally made directly from steel blanks, while small welded pipes and thin-walled welded pipes only require Just weld directly through the steel strip.

2. How many faces need to be welded when welding the pipe?

Thin-walled welded square pipes are square rectangular pipes formed by welding steel strips. When welding, how many faces need to be welded is a problem that many friends are more concerned about. Here is a brief introduction for you. In fact, when welding square pipes, it is generally necessary to weld at least two sides, because if only one side is welded, it is easy to cause the welded square pipe to break due to insufficient strength; if higher strength is required, three or even four sides can be welded. All welded.

3. Can welding square pipes be welded on all sides?

Can. Welded square pipes can be welded on all four sides, which makes them stronger. Especially for some small-sized welded square pipes, such as 50*50mm welded square pipes, they need to be fully welded on all sides, otherwise they are prone to insufficient strength, breakage, etc. Condition.

4. Precautions when welding square pipes

(1) Stress relief work must be performed during the welding process. Partial welding and welding can be performed so that the stress can be continuously released; or in split welding, the stress generated by the welding can be eliminated by hammering the welding joint.

(2) It is best to weld square pipes and welding rods at room temperature. When the on-site conditions cannot reach room temperature, the square pipe and welding rods should be heated to reduce brittle fracture caused by thermal expansion and contraction. If the temperature is low or the temperature difference between day and night is large, heating is necessary.

(3) When welding, the welding stress can be immediately eliminated by aligning several small round holes on the square tube. It is not recommended to pull the weld seam during the welding process, that is, do not weld the butt part immediately.

How to overlap square tubes

Square tubes are widely used, including structural square tubes, decorative square tubes, construction square tubes, mechanical square tubes, etc. When using them, multiple square tubes usually need to be overlapped together. So how do you connect square tubes?

1. Compression type

Insert the square tube into the nozzle of the pipe fitting and tighten it with a nut. Use spiral force to compress the casing at the nozzle through the sealing ring to act as a seal and complete the square tube connection. Scope of application: DN (nominal diameter) ≤ 150mm, can be installed in the open or concealed.

2.Welding type

Ring-shaped argon arc welding is performed on the usual socket-type pipe fittings and supporting parts to achieve a sealing effect and complete the supporting connection. Scope of application: Pipes in public buildings and large buildings, with DN between 15mm and 100mm. For DN greater than 100mm, conventional butt welding is the most common method; it can be installed exposed and concealed indoors, or buried outdoors.

3.Heat shrinkable pipe fittings

When connecting square pipes, on-site welding can be used. Since welding points cannot be processed at the construction site, heat-shrinkable pipe fittings are used for supplementary sealing. A rubber welding sleeve is put on the pipe welding point, and then a special cross-linked polyethylene sleeve is put on it, which shrinks under the action of heat, thereby achieving Shrink seal. Applicable scope: pipes with DN below 400mm.

4. Taper thread type

Annular argon arc welding is performed on the externally threaded sleeve and matching parts, and the internally threaded pipe fittings are connected with tapered threads for sealing to complete the matching connection. The applicable range is DN between 65mm and 100mm. It is suitable for pipes in public buildings and large buildings. It can be used in harsh environments such as foundation sinking, high temperature and high pressure.

5. Limit compression test

The square pipe adopts flange or port welding ring, and the connection method is a union or semi-union connection. After compressing the rubber sealing ring limit seal by 20%-30%, it enters the metal sealing groove and uses a limit seal to protect the sealing element. Joints can be made of copper or carbon steel. The applicable range is DN below 400mm, which is suitable for harsh environments such as foundation sinking and various types of high temperatures and pressures.

6. Quick connect flange type

Perform annular argon arc welding on the flange and matching parts, and use a quick clamp to compress the sealing gasket between the flanges to act as a seal and complete the matching connection. The applicable scope is DN 15mm-100mm, for pipes in public buildings and large buildings.

7. Union type quick connect flange

The traditional flange is turned into a union flange, the square tube port is flanged or welded, the ring is embedded in a groove, and a sealing rubber piece is placed in the groove, and the limit compression method is used to protect the sealing element. The applicable range is DN below 400mm and can be used as underground pipe.

8. Pressure type

Insert the square tube into the pipe fitting. Both ends of the pipe fitting have protruding U-shaped grooves with built-in sealing rings. Use a special pipe fitting tool to clamp the socket to connect. Scope of application: .DN≤100mm, can be installed in the open or concealed.

What are the precautions for connecting stainless steel square pipes?

1. Whether it is a square tube or a rectangular tube, it should be supplied by the supplier. Square and rectangular tubes of different grades and materials should not be connected together.

2. When the square pipe is connected to accessories such as threaded valves, water nozzles, water meters, etc., the thread must not be threaded on the square pipe, but should be transitioned through threaded accessories such as conversion joints.

3. When underground connection is required, please note that the square pipe should not be in direct contact with cement, cement mortar, or concrete. Plastic-coated thin-walled welded pipes should be used or anti-corrosion tape should be wrapped around the outer wall of the pipe.

4. When connecting square pipes, be careful to avoid sharp objects hitting the square pipes. When using seals to connect, be careful to avoid oil or other dirt from contaminating the seals.

Read more: What is square tube(SHS)? or What is the difference between square tube and rectangular tube?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.