In oil, gas, and geological drilling

engineering, weight of drill pipe is one of the core parameters in drilling design, equipment selection, and well

control calculations. Accurately determining drill pipe weight is crucial not

only for the rig's hook load capacity and drill string strength verification

but also for drilling efficiency and operational safety.

This article will systematically analyze

drill pipe weight from multiple dimensions, including specification

relationships, weight calculation methods, weight tables, and influencing

factors.

Drill Pipe Weight and Specifications

The weight of drilling pipes is closely

related to their specifications. The weight of drill pipes is mainly determined

by the following geometric parameters:

Outer Diameter (OD)

Wall Thickness (WT)

Single Length (Range)

Steel Density (usually carbon steel or low

alloy steel)

Tool Joint Weight

According to the American Petroleum

Institute (API) standards, the common drill pipe diameter ranges from 60.3 to

139.7 mm, and the length mainly varies from 8 to 10 meters. Within these

specification ranges, the weight of a single drill pipe generally ranges from

74.56 to 335.7 kg. However, in actual use, other non-standard drill pipe

specifications may be encountered, and their weights will vary.

How to Measure Drill Pipe Weight

1. Obtain the Drill Pipe Outer Diameter

(OD)

The outer diameter (OD) is the external

dimension of the drill pipe body, directly affecting its cross-sectional area.

This basic dimension is usually printed on the drill pipe or found in the

specification sheet.

2. Determine the Wall Thickness

This measurement can be obtained from the

manufacturer's specifications or measured using a dedicated ultrasonic

thickness gauge. A thicker wall means more material, resulting in a heavier

drill pipe and stronger structural integrity.

3. Determine the Steel Grade and Density

The steel

grade of the drill pipe (e.g., E-75, X-95, G-105, S-135) specifies the

material's strength characteristics, but density is crucial for weight

calculations.

Please consult the manufacturer's

specifications or industry standards (e.g., API 5DP) for accurate density

values. By combining the drill

pipe sizes, the weight per foot or meter of drill pipe can be

accurately calculated, which forms the basis for calculating the total weight

of the drill string.

4. Consider the Weight and Length of the

Joints

Joints are the threaded connections at both

ends of the drill pipe and are typically heavier and thicker than the drill

pipe body.

The dimensions of the joints (outer

diameter, inner diameter, and length) must be considered, as they significantly

affect the total weight of each drill pipe joint.

The total length of the pin and sleeve ends

affects the effective weight distribution. Manufacturers typically provide a

"nominal weight per foot," which already includes the average weight

of the tool joints.

5. Calculate the Nominal Weight per Foot

The nominal weight per foot is usually an

average weight provided by the manufacturer, which simplifies the calculation

of the entire drill string.

This value is derived by dividing the

weight of the pipe body and the heavier tool joints by the weight of a standard

length of pipe joint.

Drill Pipe Weight Calculation Formulas

1. Weight per Foot (lb/ft) Calculation

Formula

The formula is: Wt/Ft = 10.69 * (OD – Wall Thickness) * Wall Thickness

OD, WT Units: Inches

Result: Pounds per foot (lb/ft)

2. Metric Conversion Formula

kg/m = lb/ft × 1.488

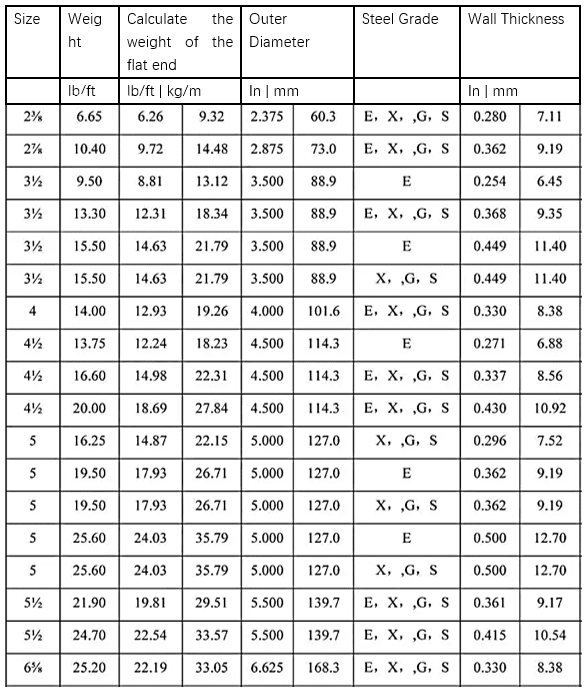

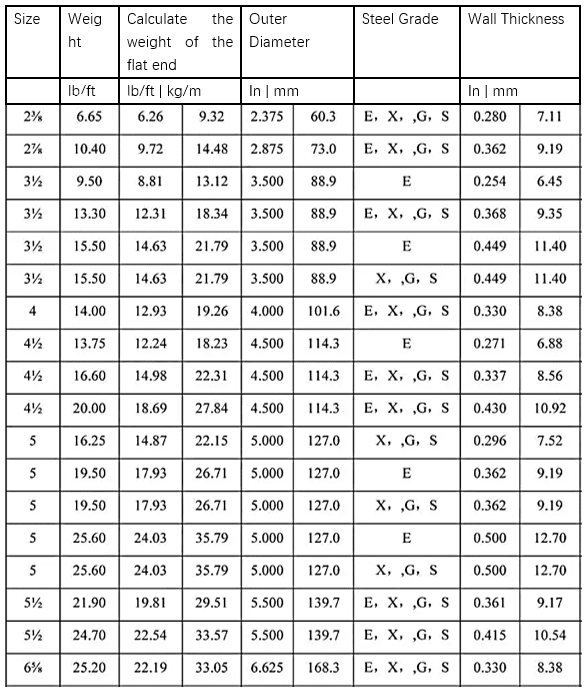

Drill Pipe Weight Chart

Nominal Weight per Foot: This is the

standard weight used for calculation, usually provided by the manufacturer. It

is the average weight taking into account the weight of the pipe body and

fittings.

Outer Diameter (OD): The diameter of the

outer part of the pipe. A larger outer diameter generally corresponds to a

heavier pipe.

Wall Thickness/Weight per Foot: For the

same outer diameter, different wall thicknesses will result in different

weights per foot and different strength grades.

Steel Grade: High-strength steel grades

(e.g., S-135) will affect the ultimate strength-to-weight ratio, although the

density differences between commonly used grades are small.

Common Drill Pipe Weight in kg

|

Nominal OD (inches)

|

Typical Weight (kg/m)

|

|

2 3/8

|

7.22 – 9.89

|

|

2 7/8

|

9.52 – 15.48

|

|

3 1/2

|

14.14 – 23.07

|

|

4

|

17.63 – 24.71

|

|

4 1/2

|

20.46 – 29.76

|

|

5

|

24.11 – 37.23

|

|

5 1/2

|

29.02 – 41.37

|

|

5 7/8

|

33.04 – 48.06

|

Drill Pipe Weight in Special Materials

Some drill pipes are made of special

materials, such as high-strength aluminum alloy drill pipes and carbon fiber

composite drill pipes. These special materials have lighter weight, higher

strength, and corrosion resistance, and are widely used in high-end fields such

as deep-sea drilling and oilfield exploration.

The weight per meter of these special

material drill pipes is usually lower than that of conventional steel drill

pipes of the same type.

1. Carbon Steel/Alloy Steel Drill Pipe

Density approximately 7.85 g/cm³, standard weight, used in conventional oil and gas wells.

2. High-Strength Alloy Steel Drill Pipe

Density approximately 7.80 g/cm³, similar weight, but higher strength, used in deep and ultra-deep

wells.

3. Aluminum Alloy Drill Pipe

Density approximately 2.8 g/cm³, weight reduced by 40%+, used in directional and extension wells.

4. Composite Material Drill Pipe

Customizable, extremely lightweight, used

in specialized high-end projects.

Drill Pipe Weight in Common Diameter

1. Weight per Meter of 26mm Diameter Drill

Pipe

For 26mm diameter drill pipe, the weight per meter varies depending on

the material and manufacturing process. For example, a certain brand of

high-strength steel drill pipe weighs approximately 2.3kg per meter.

2. Weight per Meter of a 42mm Diameter

Drill Pipe

Similarly, the weight per meter of a 42mm

diameter drill pipe is also affected by the material and manufacturing process.

For example, a high-quality alloy steel drill pipe from another brand weighs

approximately 6.8 kg per meter.

Factors Affecting Drill Pipe Weight

Besides length and diameter, the weight of

a drill pipe is also affected by the following factors:

1. Material Density

Differences in the density of different

drill pipe materials will lead to variations in weight.

2. Wall Thickness Design

Thicker-walled drill pipes are heavier but

stronger. In the API 5DP system, different wall thicknesses typically

correspond to different weight classes.

3. Connector Type

Different connector structures result in

significant weight differences. Tool joints are the thickened threaded

connections at both ends of the drill pipe, and their weight typically accounts

for 15%–25% of the total weight of the drill pipe.

4. Coatings and Threads

Additional coatings or drill

pipe threads can also cause slight variations in weight. Although the

increase in weight per pipe is limited, the cumulative weight change is

significant when hundreds of drill pipes are used in a drill string.

FAQ

1. Does the drill pipe weight include the

tool joint?

In engineering and API 5DP standards, the

"nominal weight" is typically used, which is the weight of the drill

pipe plus the average weight of the tool joint.

2. Why do drill pipes with the same outer

diameter have different weights?

This is because of different weight

classes.

With the same outer diameter (OD), drill

pipes can be configured with different weight classes by varying the wall

thickness (WT), corresponding to different weights per unit length and

load-bearing capacities.

3. How should weight information be

correctly described when purchasing drill pipes?

A complete and standardized description

should include: Outer diameter × Weight class × Steel grade × Length class × Applicable standard

For example:

5" × 25.6

lb/ft × G105 × R2 × API 5DP

Summary

In summary, drill pipe weight is not just a

parameter, but the foundation of the entire drilling system design. Accurate

weight data helps improve drilling safety, optimize rig selection, reduce

downhole accident risks, and enhance international customers' trust in the

supplier's expertise.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.