What Is API 5DP Drill Pipe

API 5DP drill pipe is a type of OCTG pipe, a

threaded pipe at the rear end used to connect surface drilling equipment to the

mill or bottom-hole assembly at the bottom of the drilling rig.

Its purpose is to transport drilling mud to

the drill bit and to coordinate with the drill bit to raise, lower, or rotate

the bottom-hole assembly. Drill pipe must be able to withstand significant

external pressure, twisting, bending, and vibration.

In oil and gas exploration and mineral

production, API 5DP drill pipe can be reused multiple times and is an

indispensable component in drilling operations.

For example, S135 requires a yield strength

of ≥135 ksi (approximately 931 MPa), making it suitable

for ultra-deep well operations.

API 5DP Drill Pipe Size Range

1. Size Range

2

3/8" to 5 1/2" (60.3 mm to 139.7 mm).

2. Thickness Range

6.5 mm to 12.7 mm

3. Length

R1, R2, R3.

Ranger 1 (R1) is the shortest length and is

more commonly used to size production tubing or casing pipe,

ranging from 18 to 22 feet.

Ranger 2 (R2) is considered the standard

length for drill pipe and ranges from 27 to 31 feet.

Ranger 3 (R3) is common in casing and is

also used in deepwater drilling applications. The increased length reduces the

number of tool joints per drill pipe.

API 5DP Drill Pipe Steel Grade

API 5DP is designed specifically for drill

pipe and specifies material grades such as E75, X95, G105, and S135 (the number

represents the minimum yield strength in ksi). The differences are primarily in

yield strength, tensile strength, and toughness:

1. E75

Yield strength ≥ 75

ksi (517 MPa) and is primarily used in shallow or conventional wells.

2. X95

Yield strength ≥ 95

ksi (655 MPa), suitable for medium-deep well operations.

3. G105

Yield strength ≥ 105 ksi (724 MPa), suitable for deep wells and high-intensity operating

environments.

4. S135

Yield strength ≥ 135 ksi (931 MPa), suitable for ultra-deep wells, high-pressure wells, and

complex formations.

API 5DP Drill Pipe Mechanical Properties

Mechanical property requirements for

different API 5DP drill pipe grades:

|

Pipe body

|

Grade

|

Yield strength

Min

|

Yield strength

Max

|

Tensile strength

Min

|

Elongation

|

Charpy impact

|

|

E75

|

75000 Psi / 517 MPa

|

1E+05 Psi / 724 MPa

|

1E+05 Psi / 689 MPa

|

625000A0 .2/U0.9

|

Average 80 J

Single 65 J

|

|

X95

|

95000 Psi / 655 MPa

|

1E+05 Psi / 862 MPa

|

1E+05 Psi / 724 MPa

|

Average 80 J

Single 65 J

|

|

G105

|

1E+05 Psi / 724 MPa

|

1E+05 Psi / 931 MPa

|

1E+05 Psi / 793 MPa

|

Average 80 J

Single 65 J

|

|

S135

|

1E+05 Psi / 931 MPa

|

2E+05 Psi / 1138 MPa

|

1E+05 Psi / 1000 MPa

|

Average 80 J

Single 65 J

|

|

Weld

zone

|

Tool joint

|

1E+05 Psi / 827.4 MPa

|

-

|

1E+05 Psi / 965.3 MPa

|

≥13%

|

HBW ≥285

Average 80 J

Single 65 J

|

|

E75

|

75000 Psi / 517 MPa

|

-

|

1E+05 Psi / 689 MPa

|

Average 40 J

Single 27 J

|

|

X95

|

88000 Psi / 609 MPa

|

-

|

1E+05 Psi / 712 MPa

|

Average 40 J

Single 27 J

|

|

G105

|

95000 Psi / 655 MPa

|

-

|

1E+05 Psi / 724 MPa

|

Average 40 J

Single 27 J

|

|

S135

|

1E+05 Psi / 724 MPa

|

-

|

1E+05 Psi

|

Average 40 J

Single 27 J

|

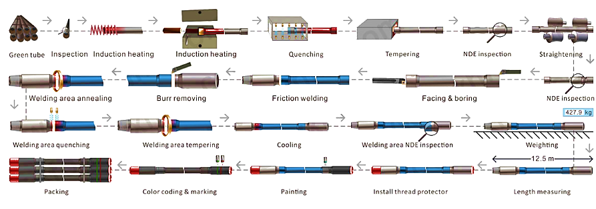

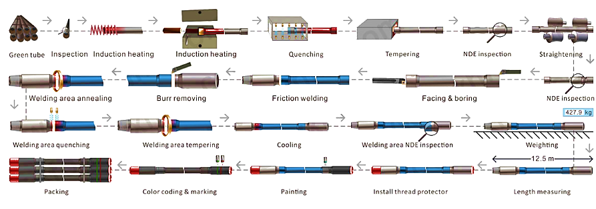

API 5DP Drill Pipe Manufacturing Process

Drill pipe is manufactured in strict

accordance with the API 5DP standard. Drill pipe manufacturing is a strictly

controlled process designed to ensure that the final product meets the

stringent standards required for drilling operations.

API 5DP Drill Pipe Manufacturing Process

Material selection → Pipe forming → Heat treatment → Quenching and tempering → End upset → Tool joint welding → Inspection and testing → Marking and coating.

API Specification 5DP Drill Pipe Types

1. Standard Drill Pipe

The most common type of drill pipe.

Used for conventional drilling in onshore

and offshore environments.

HWDP is thicker and heavier than standard

drill pipe, designed to increase the weight of the drill string, reduce

buckling, and improve stability.

Used for directional drilling and extended

reach wells.

3. Auger Drill Pipe

Auger drill pipe features spiral grooves to

reduce friction and wear during drilling. Used in operations where friction

reduction is critical.

4. Square Drill Pipe

Square drill pipe is less common and

features a square cross-section, providing increased rigidity. Used in specific

drilling scenarios requiring a rigid drill string.

5. Hexagonal Drill Pipe

Hexagonal drill pipe has a hexagonal

cross-section for increased torsional strength. Used in high-torque drilling

operations.

API 5DP Drill Pipe Threads

The connections between drill pipe sections

are critical to maintaining the integrity of the drill string. API 5DP drill

pipe has several connection types:

1. Internal Flush (IF) Threads

This flush internal profile design reduces

pressure drop and turbulence, making it suitable for high-pressure wells.

2. Full Hole (FH) Threads

This connection features a larger bore

diameter and larger fluid passages, making it suitable for deep wells and

high-flow mud transport.

3. API Conventional (API REG) Threads

This connection offers a wide range of

applications and is robust and durable. It is commonly used in standard

drilling operations.

4. Numerical Connection (NC)

This high-torque design is commonly used in

deep wells, hard formations, and complex drilling conditions.

Differences between API 5D and API 5DP Drill

Pipe

Both API 5D and API 5DP are drill pipe

standards developed by the American Petroleum Institute (API). To address the

shortcomings of API 5D and provide a comprehensive specification covering the

entire drill pipe lifecycle, API released API 5DP to replace API 5D.

Simply put, the core differences between

them are:

1. API 5D

An earlier standard that only regulates the

drill pipe body (raw material), primarily controlling dimensions, chemical

composition, and basic mechanical properties.

2. API 5DP

An upgraded standard that covers the entire

finished drill pipe product, including the pipe body, welds, joints, and final

inspection requirements, more closely resonating with actual operating

conditions.

Summary

API 5DP drill pipe is an indispensable and

critical tool in oil and gas drilling. Its strict material grades, dimensional

standards, mechanical property requirements, as well as standardized

manufacturing processes and joint designs, ensure safe and efficient drilling

operations.

Read more: API 5DP Drill Pipe Specs & Sizes or Guide To Drill Pipe Steel Grades

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.