Drill pipe can be welded, but only for specialized welding in specific

locations, with specific steel grades, and under specific process conditions.

Conventional API drill pipe should not be arbitrarily welded on-site as a

load-bearing connection; otherwise, it will seriously affect safety and even

cause downhole accidents.

Basic Principles of Drill Pipe Welding

Drill pipe welding typically refers to:

repair welding of non-load-bearing parts; welding of pup joints or accessories; and friction welding (inertia welding) to connect the drill

pipe body to the tool joint.

In the API

Spec 5DP standard, the connection between the drill pipe body and the

tool joint uses friction welding, not manual arc welding. The quality of drill

pipe welding directly affects the efficiency and safety of drilling operations.

Key Processes in Drill Pipe Welding

The following key points need to be

mastered during drill pipe welding:

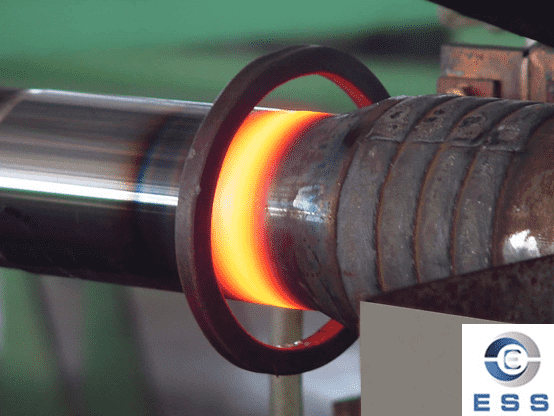

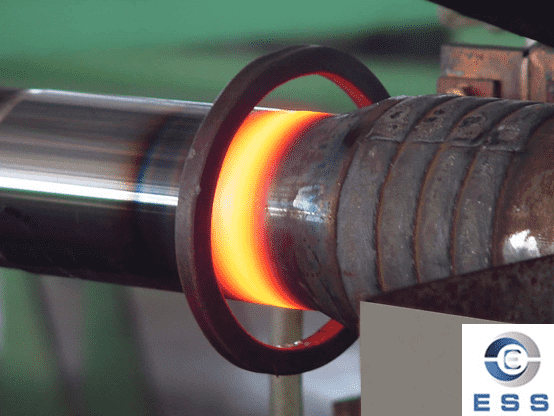

1. Drill Pipe Preheating

Drill pipe needs to be preheated before

welding to reduce welding stress and deformation. Common preheating

temperatures: 100–250°C

(depending on steel grade).

2. Welding Parameter Control

This includes controlling parameters such

as current, voltage, wire feed speed, and gas flow rate. Adjustments need to be

made according to the material being welded and the specific requirements.

3. Post-Welding Treatment

This includes steps such as weld smoothing,

slag removal, and weld quality inspection.

Drill Pipe Welding Machine and Tools

1. Welding Equipment

DC welding machine; Automatic or

semi-automatic welding system; Friction welding machine (factory only).

2. Auxiliary Tools

Preheating device (induction or flame);

Temperature measuring instrument (infrared/thermocouple); Weld grinding and

flaw detection equipment (UT/MT).

Common Welding Rods for Drill Pipe

Commonly used welding rods for drilling

pipes mainly include the E5015, E5016, E5018, E55 series, and E6010 series. The

characteristics of these welding rods are as follows:

1. E5015 Welding Rod

This welding rod is an alkaline welding rod

with high current density, good weld formation, strong weld toughness, and good

heat resistance. It is suitable for welding medium and thick plates.

However, it produces more welding spatter,

requiring careful protection.

2. E5016 Welding Rod

This welding rod is also an alkaline welding

rod, typically used for welding large steel structures and high-strength steel.

Its tensile strength is higher than E5015.

However, it can cause significant shrinkage

stress when welding thin steel plates, requiring additional protection.

3. E5018 Welding Rod

This welding rod is an alkaline welding rod,

commonly used for welding important steel structures. It produces high-quality

welds with good tensile strength and crack resistance.

However, it needs to be thoroughly baked

dry to prevent hydrogen generation that could render the weld unusable.

4. E55 Series Welding Rod

This welding rod is a low-hydrogen

sodium-type steel structure welding rod, suitable for welding various ordinary

steels and low-alloy steels.

It produces less spatter, has good weld

bead formation, and is highly resistant to impact and cracking. However, the

intense arc light can affect the nervous system, so eye protection is

necessary.

5. E6010 Series Welding Rods

These welding rods are magnesium-sodium

type, typically suitable for fieldwork. They offer good weld bead formation and

penetration, and can be used normally in adverse weather and environmental

conditions, but require a high level of operator skill.

Precautions Before Welding

1. Thoroughly clean the drill pipe before

welding to prevent contamination and defects.

2. Select appropriate welding materials and

welding processes based on the drill

pipe steel grade and material before welding.

3. During welding, simultaneously record

welding parameters and weld quality for subsequent inspection and tracking.

Problems in Drill Pipe Welding

1. Incomplete Weld Penetration

This may be due to insufficient welding

temperature or an unsuitable ratio of welding material to base material.

Solutions include increasing the current or using higher quality welding

materials.

2. Weld Cracks

This may be due to excessively high welding

temperature or excessive welding stress.

Solutions include controlling welding

parameters, preheating, and introducing hydrogen gas.

3. Weld Deformation

This may be due to improper control of

welding parameters or insufficient preheating.

Solutions include mastering

welding parameters, performing appropriate preheating, and post-treatment.

Read more: NC50 Drill Pipe Sizes and Specs

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.