Din EN 10220

Din en 10220 also called seamless and welded pipes - dimensions and masses per unit length. In translating the European quasi-standard ENV 10220 to EN 10220, ECISS/TC 29 considered it necessary to avoid any conflict with ISO 4200:1991 and to minimize deviations because of the international trade in steel pipes and tubular products.

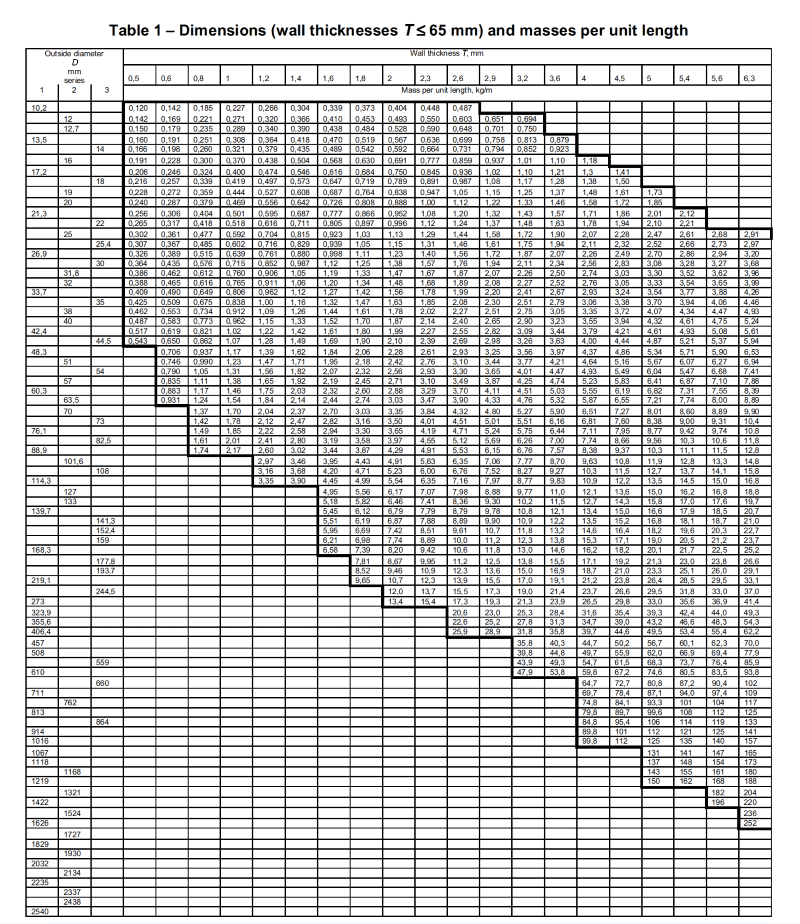

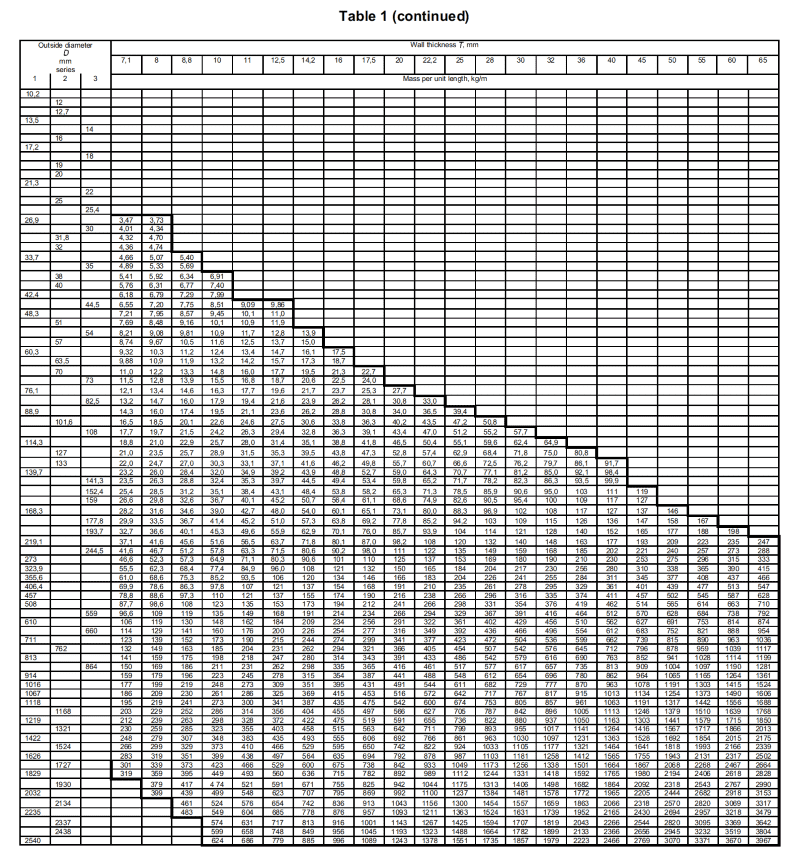

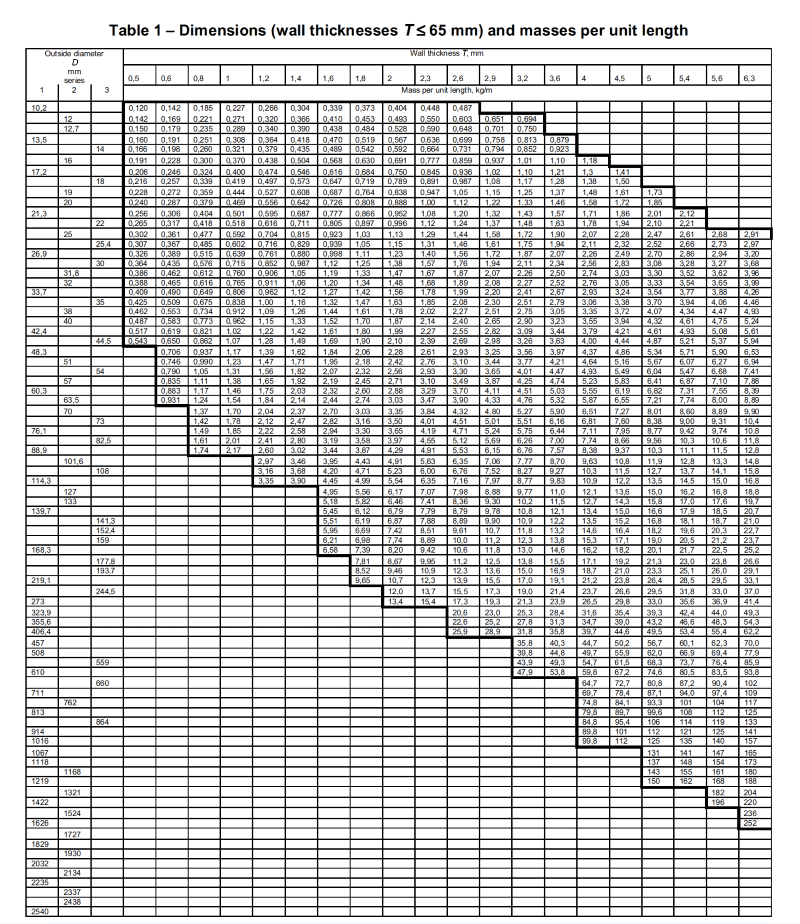

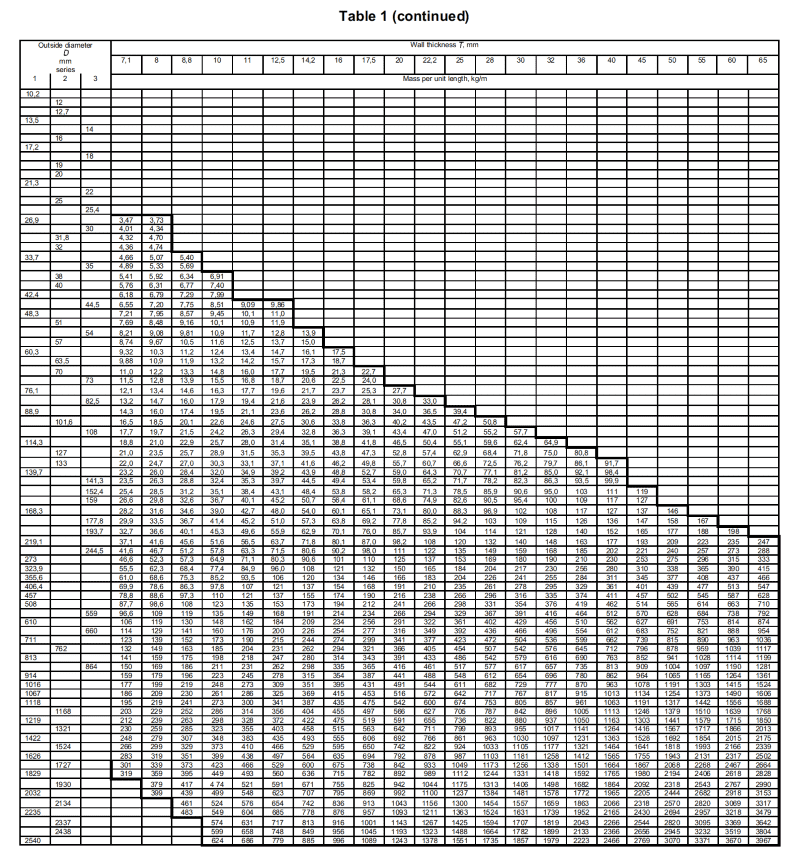

Table 1 of ENV 10220 is the same as Table 2 of ISO 4200:1991 and therefore remains unchanged for EN 10220.

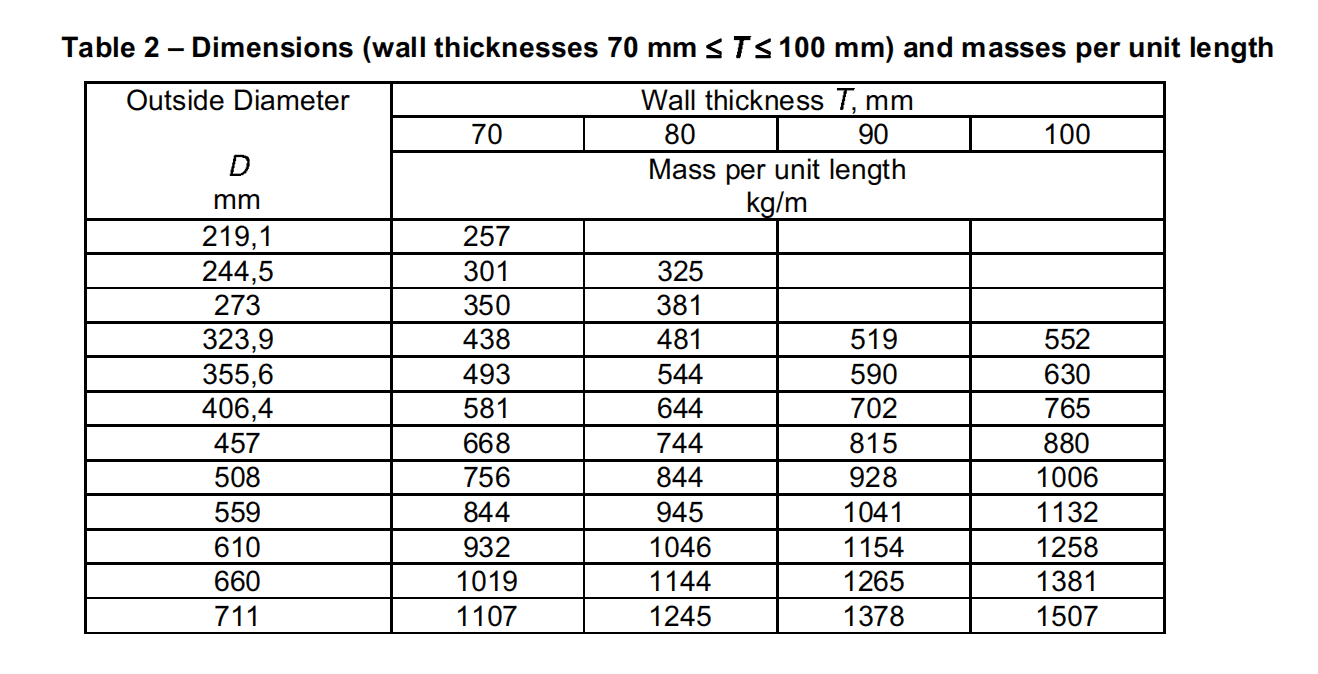

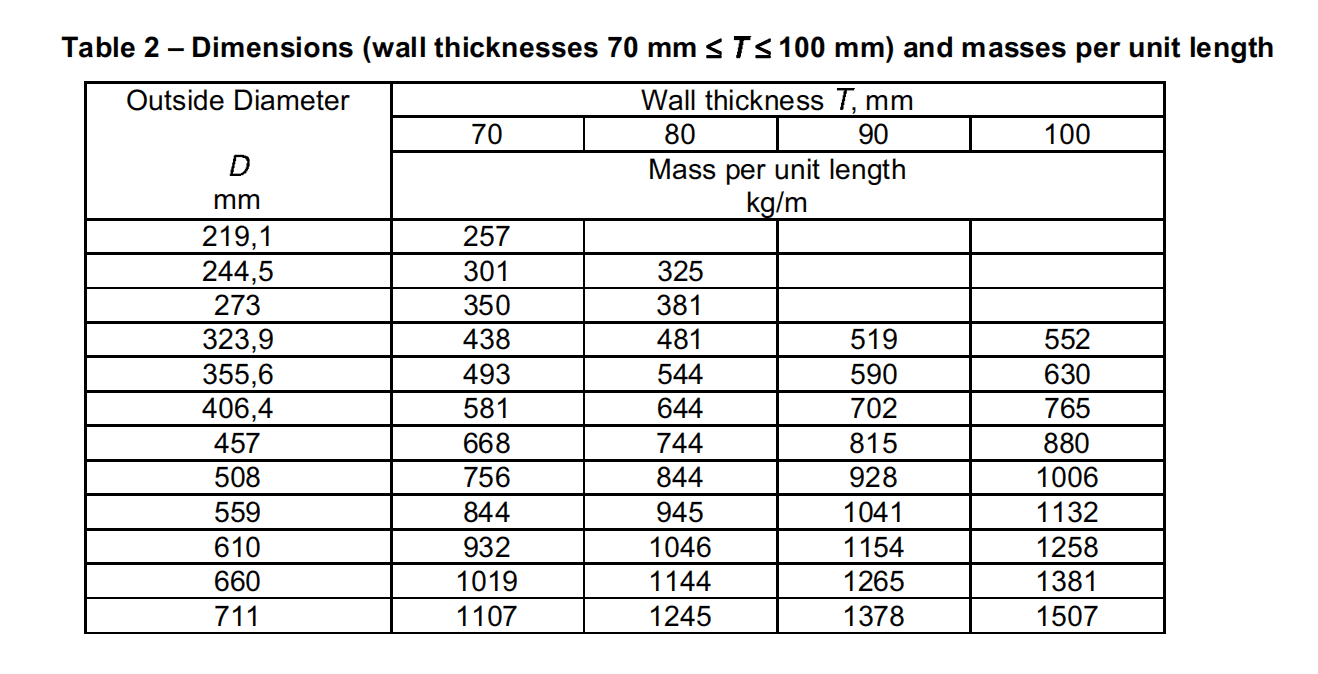

Table 2 of EN 10220 contains dimensions for thick-walled pipe not covered by ISO 4200:1991.

The EN 10220 and EN 1127 norms cover dimensions and tolerances for European pipes, carbon/alloy steels and stainless steels respectively. While EN 10220 and 1127 are used in Europe, ASME B36.10 and ASME B36.19 cover dimensions and tolerances for American standard pipe.

All parts of the European standard series EN 10305 on steel tubes for precision applications contain tables with preferred dimensions specific to each part of the standard series and to the products and areas of application specified therein. Therefore, the preferred dimensions of precision tube in Table 3 of ENV 10220 have become unnecessary and are not included in this standard.

This document supersedes ENV 10220:1993.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and the United Kingdom.

Key aspects of EN 10220 include

EN 10220 aims to standardize the dimensional specifications of steel pipes across Europe, promote interoperability, and ensure that steel pipes meet the quality and performance requirements of various applications.

1. Scope

Covers seamless and welded steel pipes for pressure purposes (except submerged arc welding), full-circumference magnetic particle testing for detecting longitudinal flaws, and ultrasonic testing for detecting laminar flaws.

2. Outside Diameter and Wall Thickness

The standard provides detailed charts specifying the permissible variations in outside diameter and wall thickness of steel pipes, which are critical to ensuring that the pipes are suitable for the intended pressure and structural requirements.

3. Length Tolerance

EN 10220 also specifies tolerances on pipe lengths, including standard lengths and permissible variations. This is crucial to ensuring that the pipes can be correctly installed in designed piping or structural systems without excessive modifications.

4. Form Tolerance

Includes straightness and roundness tolerances, ensuring that the pipes can be accurately installed and welded in a variety of configurations and applications. EN 10220 provides a comprehensive set of dimensional specifications and tolerances that help ensure the quality and compatibility of steel pipes used in the construction, engineering, and manufacturing industries throughout Europe. This standardization helps improve the efficiency of steel pipe design, specification, and procurement, thereby enhancing the overall safety, reliability, and performance of piping systems and structural projects.

Scope of application

1. Scope

This European Standard specifies, for seamless(

smls pipe) and welded circular steel pipes for general purposes such as mechanical, pressure and structural applications, that:

- preferred dimensions for outside diameter and wall thickness in millimeters and

- Mass per unit length in kilograms per meter of plain-end tubing.

The technical committees of ECISS and CEN shall select these preferred dimensions for their product or functional standards, as appropriate.

Outside diameters are grouped into three series that reflect the availability of piping system accessories. This classification of outside diameters into different series and preferred wall thicknesses indicates the range of steel pipes that are commonly produced.

NOTE: Information on steel pipe dimensions for special applications can be found in other European standards such as prEN 10255, EN 10305 series, EN ISO 11960 and EN ISO 11961, information on stainless steel pipe dimensions in EN ISO 1127.

2. Regulation

Seamless and welded round steel pipes for general purposes (e.g. mechanical, pressure and structural applications), as follows:

Preferred dimensions in mm for outside diameter and wall thickness and mass per unit length in kg/m of plain-end pipe.

The technical committees of ECISS and CEN shall select these preferred dimensions for their product or functional standards, as appropriate.

Outside diameters are divided into three series reflecting the availability of piping system accessories (see Chapter 4). This classification of outside diameters into different series and preferred wall thicknesses indicates the range of steel pipes that are commonly produced.

3. Notes

Information on steel pipe dimensions for special applications can be found in other European standards such as prEN 10255, EN 10305 series, EN ISO 11960 and EN ISO 11961, information on stainless steel pipe dimensions in EN ISO 1127.

Terms and definitions

For this purpose, the terms and definitions in prEN 10266 apply.

Outer diameter classification

The outer diameters given in Tables 1 and 2 are divided into three series, which can be described in the following ways:

Series 1: the outside diameter of which all accessories required for the construction of the piping system have been standardized;

Series 2: outside diameter not standardized for all accessories;

Series 3: There are few standardized accessories for outside diameters.

NOTE 1: For pipe intended to be used as a component of a piping system, it is recommended to select an outside diameter of Series 1 in Table 1. Tubing with outside diameters in series 2 and 3 may not be available or readily available.

NOTE 2: Heavy-wall pipe fittings dimensioned in Table 2 may not be available regardless of which series the relevant outside diameter in Table 1 is assigned to.

Calculation method of mass per unit length

The masses per unit length given in Tables 1 and 2 have been calculated to at least five significant figures from the outside diameter D and wall thickness T using the formula given below. Values less than 100 are rounded to three significant figures, and larger values are rounded to the nearest whole number.

M=(D-T)Tx0,02466151) kg/m

Where

M is the mass per unit length in kg/m,

D is the specified outer diameter

T is the specified wall thickness in millimeters.

Calculated values can also be applied to tubes with different density values, but must be multiplied by a factor

-- 1,015 for austenitic stainless steel2)

-- 0,985 for ferritic and martensitic stainless steel3).

Note: EN 10088-1 provides different density values for various stainless steel grade groups that may be used for calculation purposes.

Dimensions and mass per unit length

Table 1 gives the dimensions, including the outer diameter D, from the 3 series described in Chapter 4, the relevant wall thickness Ts 65 mm and the calculated mass per unit length of the plain-end tube.

Table 2 gives the dimensions consisting of the outer diameter D and the associated wall thickness T from 70 mm to 100 mml and the calculated mass per unit length of plain-end tubes.

Summary

EN 10220 is the European standard

for dimensions and tolerances for seamless and welded steel pipes. EN 10220 is

widely used, primarily in the oil and gas, chemical, construction, and water

industries. Covering the outside diameter (OD) and wall thickness (WT) of steel

pipes, it provides clear guidelines and uniform specifications for engineering

design and manufacturing, ensuring consistency and interchangeability between

pipes produced by different manufacturers.

Read more: EN10220 vs EN10210 Pipes or EN 10220 Pipe Weight Chart

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.