Oil drill pipe is an indispensable key component in oil and gas drilling

engineering. It is a hollow steel pipe used to connect the drilling rig's

surface equipment to the drill bit at the bottom of the well. It serves as a

channel for drilling fluid circulation and is responsible for transmitting

torque and tension to the bottom-hole tools. Drill pipe must possess high

strength, good toughness, fatigue resistance, and corrosion resistance to cope

with the complex downhole environment.

Drill pipe withstands enormous axial

tensile forces, torque, internal and external pressure differentials, bending,

and vibration during drilling. Therefore, materials, heat treatment,

manufacturing precision, and joint design must strictly comply with international

standards (such as API

SPEC 5D and API SPEC 7-1).

Main Functions of Oil Drill Pipe

1. Power Transmission

Transmits the torque of the drilling rig

spindle to the drill bit at the bottom of the well, causing the drill bit to

rotate and break up the formation.

2. Drilling Fluid Delivery

Drilling fluid flows from the surface

through the drill pipe to the drill bit, used to cool the drill bit, carry

cuttings, and balance bottom-hole pressure.

3. Transferring Drill Pressure

Pressure is transferred to the drill bit

through the weight of the drill string itself or by applying additional drill

pressure to improve drilling efficiency.

4. Connecting Function

Tools such as kelly

pipe, standard drill pipe, heavy

weight drill pipe and drill collars are reliably connected to form a

complete drill string.

Material Grades of Oil Drill Pipe

According to API SPEC 5D standard, common

material grades for oil drill pipes include E75, X95, G105, and S135.

|

Steel Grade

|

Tensile Strength (MPa)

|

Typical Yield Strength (MPa)

|

Characteristics

|

|

E75

|

≥655

|

517–655

|

Suitable for shallow and medium well

depths, economical choice

|

|

X95

|

≥758

|

655–758

|

Commonly used in medium to deep wells,

strength higher than E75

|

|

G105

|

≥910

|

758–910

|

Suitable for deep wells and high torque

drilling

|

|

S135

|

≥1,034

|

931–1,034

|

Essential for ultra-deep and complex

wells, high strength and high toughness steel

|

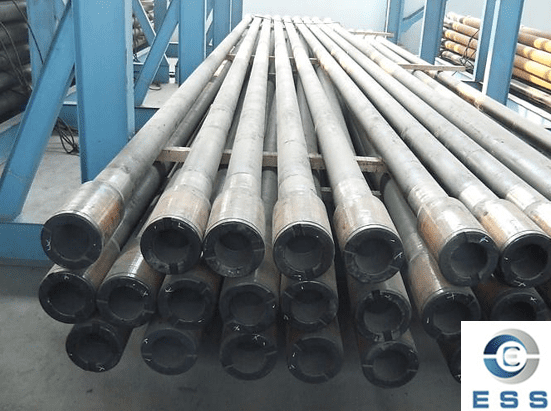

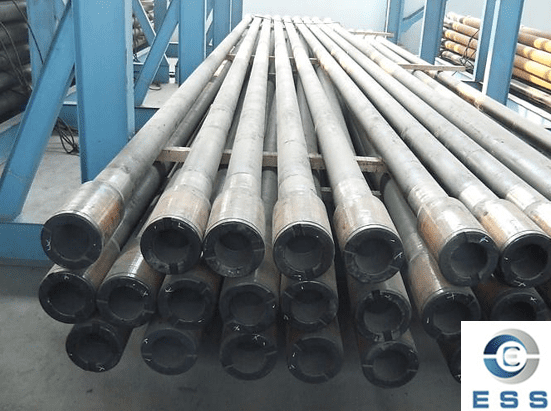

Structure of Oil Drill Pipe

Oil drill pipe mainly consists of three

parts:

1. Pipe Body

Made of high-strength seamless

steel pipe, with a wall thickness of generally 9–11 mm, it is the main body of the drill pipe.

2. Tool Joint

Made of alloy steel forgings, connected to

the pipe body by friction welding or inertia welding. The joint is thicker and

stronger than the pipe body to withstand torque and wear.

3. Welded Zone and Upset Section

Oil drill pipe is made of rolled seamless

steel pipe. To enhance joint strength, both ends of the drill pipe are

thickened.

Thickening methods include:

Internal Upset (IU)

External Upset (EU)

Combined Internal and External Upset (IEU)

The length of the thickened transition

section is generally 20–130 mm, which can improve the

fatigue life of the connection by 30–50%.

Oil Drill Pipe Lengths

Range 1: 5.49–6.71

m, shorter, commonly used for well workovers or special wells;

Range 2: 8.23–9.75

m, most common, approximately 9 meters/pipe;

Range 3: 12.19–13.72

m, commonly used in deep wells or offshore drilling.

Classification of Oil Drill Pipe

Oil drill pipe is classified into kelly

pipe, ordinary drill pipe, and heavy weight drill pipe.

The connection sequence is: 1 kelly pipe +

n standard drill pipes (determined by well depth) + n heavy weight drill pipes

(determined by drill string assembly design).

Based on thread type, drill pipe joints are

divided into four types: IF, FH, REG, and NC.

1. Kelly Pipe

The kelly pipe is located at the top of the

drill string, usually square or hexagonal, and plays a crucial role in the

drilling process.

Function of The Kelly Pipe:

During drilling, the kelly pipe, in

conjunction with the bushing and rotating bushing, transmits the surface

rotational torque to the drill pipe, thereby driving the drill string and drill

bit.

It bears the weight of the entire drill

string.

It serves as a channel for drilling fluid

circulation.

Structure of The Kelly Pipe:

The kelly pipe consists of upper and lower

joints and a pipe body.

The pipe body is usually square or

hexagonal (square is more common in oil drilling).

2. Standard Drill Pipe

Function of The Standard Drill Pipe:

The drill pipe is a basic component of the

drill string.

Its main functions are to transmit torque

and deliver drilling fluid, and its gradually elongating characteristic allows

for continuous wellbore deepening.

Standard Drill Pipe Structure:

Drill pipe mainly consists of two parts:

the drill pipe body and the drill pipe joint.

The body, as the main structure of the

drill pipe, provides primary support and transmits power.

The joint plays a crucial role in

connecting multiple drill pipe sections to form a continuous drill string.

3. Heavy Weight Drill Pipe (HWDP)

Heavy weight drill pipe is similar to oil

drill pipe, also a hollow steel column approximately 10 meters in length.

However, each section weighs more than oil drill pipe, and its wall thickness

is two to three times that of oil drill pipe.

Functions of Heavy Weight Drill Pipe:

Heavy weight drill pipe is a downhole tool

used to add weight to drilling platforms.

It is typically installed between the drill

pipe and drill collars, transmitting power and applying pressure to the drill

bit.

It can prevent fatigue damage caused by

changes in the drill string cross-section and can replace some drill collars.

Its simple suspension method makes tripping

operations more convenient and time-saving.

Heavy Weight Drill Pipe Structure:

Heavy weight drill pipe features extended

joints, increased wall thickness, and externally thickened sections.

Carbide-coated surfaces extend its service

life.

Oil Drill Pipe Standards

API SPEC 5D (Seamless drill pipe standard)

API SPEC 7-1 (Drill string connector

standard)

ISO 10424-1 / ISO 15546 (International

equivalent standard)

NS-1™ / DS-1™ (Third-party certification standard, commonly used in the North Sea

and North American markets)

FAQ

1. What are The Common Specifications for

Oil Drill Pipe?

According to API SPEC 5D standard, common

sizes: 2

3/8" drill pipe, 2 7/8" drill pipe, 3 1/2" drill pipe,

4" drill pipe, 4 1/2" drill pipe, 5" drill pipe, and 5 1/2"

drill pipe.

2. What is The Difference Between Oil

Drill Pipe and Drill Collars?

Drill pipe is primarily used to transmit

torque and deliver drilling fluid; drill collars are primarily used to apply

drilling pressure and maintain wellbore stability; they differ in weight,

diameter, and function.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.