In oil, gas, and geological exploration

drilling operations, heavy weight drill pipes (HWDP) and drill collars are both

essential components of the drill string assembly.

What is HWDP?

Heavy weight drill pipe is a conventional

drill pipe with reinforced steel or other materials added to increase its mass

and stability, thereby increasing drilling depth and preventing bending.

What is drill collar?

A drill collar, on the other hand, is a

tool used to drill into rock or underground. It consists of a steel tube with a

round or hexagonal cross-section and a cutting bit attached to the end.

While the two share certain similarities in

appearance and purpose, their design, structure, function, and scope of

application differ significantly. Proper selection and combination can

significantly improve drilling efficiency and wellbore quality.

Structural differences

1. Heavy weight drill pipe structure

Appearance: It is somewhere between

conventional drill pipe and drill collar, generally featuring a thickened

mid-section transition structure and a diameter similar to that of conventional

drill pipe. Materials: Made of high-strength alloy steel and other materials,

the inner and outer surfaces are often chrome-plated or treated with corrosion

protection.

Features: The center section features

thicker walls, making it heavier than standard drill pipe but lighter than

drill collars. A spiral groove design is often used to reduce the risk of

differential pressure sticking.

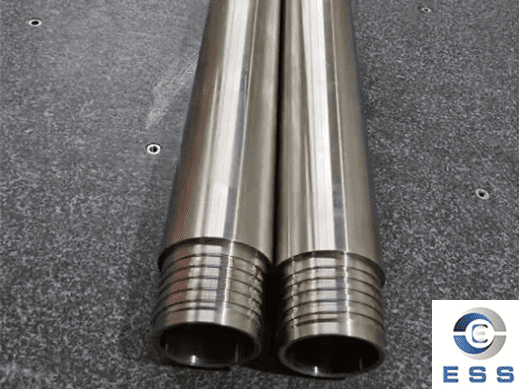

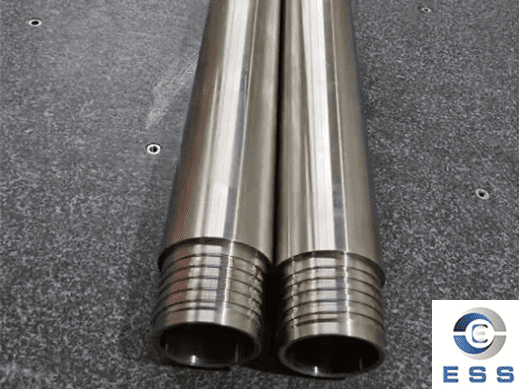

2. Drill collar structure

Appearance: Heavy, thicker walls, with

identical outer diameters at both ends. A spiral groove in the center is often

used to reduce downhole differential pressure effects.

Material: Constructed entirely of

high-strength solid alloy steel. In some cases, non-magnetic alloys

(non-magnetic drill collars) are used to meet logging requirements.

Features: Significantly heavier than

standard and heavy weight drill pipe, it primarily serves a pressure-enhancing

function.

Functional differences

1. Function of heavy weight drill pipe

Heavy weight drill pipes are widely used

for bottom drilling. Their greater weight allows the drill bit to penetrate the

formation more easily. Its main functions are as follows:

Increasing drill string weight and

increasing bit weight on bit;

Providing drill string rigidity and

reducing wellbore deflection;

Improving drill string force distribution

and reducing fatigue failure.

2. Functions of drill collars

Drill collars are typically used above the

drill bit to directly apply weight on bit. Their main functions are as follows:

Increasing bit downforce and improving

drilling efficiency;

Providing rigidity at the lower portion of

the drill string and maintaining wellbore verticality;

Reducing drill string bending and

preventing wellbore trajectory deviation.

Application differences

1. Application of heavy weight drill

pipe

Heavy weight drill pipe is suitable for

deeper drilling operations and is suitable for drilling bottom and drilling

into formations during drilling. It is typically used in directional and

horizontal wells to control the wellbore trajectory.

2. Application of drill collars

Drill collars are suitable for shallower

boreholes (often associated with poor soil quality) because they can better

adjust the depth and direction of the borehole. They are typically used in

vertical wells, deep wells, and drilling in high-hardness formations.

How to properly use drill collars and heavy

weight drill pipe?

1. Equipment Inspection

Before use, inspect the quality and

condition of the drill collar or heavy weight drill pipe to ensure there are no

cracks, deformation, or excessive wear.

2. Proper matching

Select the correct drill collar or heavy

weight drill pipe, choosing the appropriate model and length based on the

application and the hardness of the material.

3. Protective measures

Before using drill collars or heavy weight

drill pipe, ensure that all personnel have received necessary safety training

and use necessary protective equipment, such as helmets, gloves, and safety

shoes.

4. Standard operation

When using drill collars or heavy weight

drill pipe, conduct trial drilling first to determine the location and hardness

of the underground obstruction. Then, drill with gradually increasing force and

speed.

5. Real-time monitoring

Check the tool's operation at all times

during use. If any abnormality is detected, discontinue use and have it

repaired promptly.

FAQ

Q1: Can heavy weight drill pipe replace

drill collars?

No. Heavy weight drill pipe (HWDP)

primarily serves as a transition point and cannot fully provide the required

weight on bit.

Q2: Why are drill collars designed with

spiral grooves?

Spiral grooves reduce the contact area,

reduce the risk of differential pressure sticking, and improve downhole mud

flow.

Q3: How do I determine if HWDP needs to

be replaced?

When significant bending, thread damage, or

wall wear exceeding API standards occurs, it should be promptly scrapped and

replaced.

Summary

Drill collars and HWDP are both

indispensable tools in drilling. HWDP is lighter than drill collars and heavier

than standard drill pipe. Its primary function is to provide transition points

and reduce drill string fatigue, making it suitable for directional and

horizontal wells. Drill collars are heavy and rigid, acting directly on the

drill bit and primarily used in deep wells and hard formations. Drill collars

require appropriate selection based on the actual geological conditions.

Read more: The Difference Between Heavy Weight Drill Pipe & Ordinary Drill Pipe or What Is Heavy Weight Drill Pipe?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.