Drill pipe is a piece of equipment used for

oil or geological drilling, widely used in OCTG pipe systems, and its specifications and models vary according to specific

applications and needs. 2 3/8'' drill pipe refers to the diameter determined by

the drilling wellbore diameter and drill bit size. 2 3/8" drill pipe has

demonstrated reliable adaptability in various working conditions with its small

diameter and excellent performance.

2 3/8'' drill pipe specifications

This specification is usually made of seamless

steel pipe as raw material and is made after heat treatment. It is also

suitable for environments where it needs to be matched with downhole tools such

as casing pipe and pup

joints. In different projects, the reasonable matching of drill bits and

drill pipe grades can significantly improve the drilling speed and coring

quality.

|

Outer diameter (OD)

|

2 3/8" (60.325 mm)

|

|

Wall thickness (WT)

|

0.28" (7.11 mm)

|

|

Inner diameter (ID)

|

≈ 1.815" (46.1 mm)

|

|

Weight per unit length

|

4.05 lb/ft (≈ 6.02 kg/m)

|

|

Steel grade

|

G

|

|

Buckle type

|

NC26

|

|

Pound class

|

6.65

|

2 3/8'' drill pipe sizes

|

Size Outer D

|

Nominal Weight

|

Grade and Upset Type

|

Torsional Yield Strength

|

Tensile Yield Strength

|

Wall Thickness

|

Nominal ID

|

Pipe Body Section

Area

|

Pipe Body Section Modulus

|

Pipe Body Polar Section

Modulus

|

Internal Pressure

|

Collapse Pressure

|

Connection Type

|

Outside Diameter

|

Inside Diameter

|

|

2 3/8

|

6.65

|

E-75 EU

|

6,300

|

138,200

|

0.280

|

1.815

|

1.843

|

0.867

|

1.733

|

15,474

|

15,599

|

NC26

|

3 3/8

|

1 3/4

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HT26

|

3 3/8

|

1 3/4

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SLH90

|

3 1/4

|

1 13/16

|

|

2 3/8

|

6.65

|

X-95 EU

|

7,900

|

175,100

|

0.280

|

1.815

|

1.843

|

0.867

|

1.733

|

19,600

|

19,759

|

NC26

|

3 3/8

|

1 3/4

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HT26

|

3 3/8

|

1 3/4

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SLH90

|

3 1/4

|

1 13/16

|

|

2 3/8

|

6.65

|

G-105 EU

|

8,800

|

193,500

|

0.280

|

1.815

|

1.843

|

0.867

|

1.733

|

21,663

|

21,839

|

NC26

|

3 3/8

|

1 3/4

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HT26

|

3 3/8

|

1 3/4

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SLH90

|

3 1/4

|

1 13/16

|

|

2 3/8

|

6.65

|

S-135 EU

|

11,300

|

248,800

|

0.280

|

1.815

|

1.843

|

0.867

|

1.733

|

27,853

|

28,079

|

NC26

|

3 5/8

|

1 1/2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HT26

|

3 3/8

|

1 5/8

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SLH90

|

3 1/4

|

1 11/16

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GPDS26

|

3 1/2

|

1 11/16

|

|

2 3/8

|

6.65

|

Z-140 EU

|

11,700

|

258,000

|

0.280

|

1.815

|

1.843

|

0.867

|

1.733

|

28,884

|

29,119

|

XT24

|

3 1/8

|

1 1/2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

XT26

|

3 3/8

|

1 5/8

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HT26

|

3 3/8

|

1 5/8

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GPDS26

|

3 1/2

|

1 5/8

|

|

2 3/8

|

6.65

|

V-150 EU

|

12,500

|

276,400

|

0.280

|

1.815

|

1.843

|

0.867

|

1.733

|

30,947

|

31,199

|

XT24

|

3 1/8

|

1 3/8

|

|

|

|

|

|

|

|

|

|

|

|

|

|

XT26

|

3 3/8

|

1 1/2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HT26

|

3 3/8

|

1 1/2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GPDS26

|

3 1/2

|

1 1/2

|

2 3/8 drill pipe weight

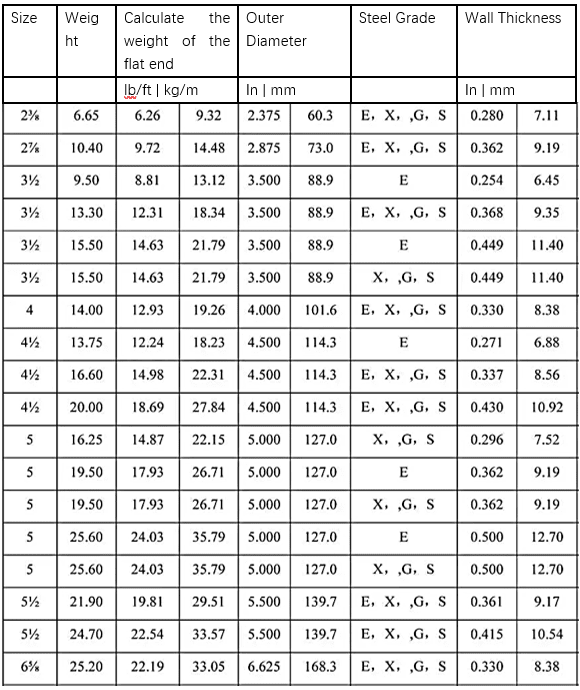

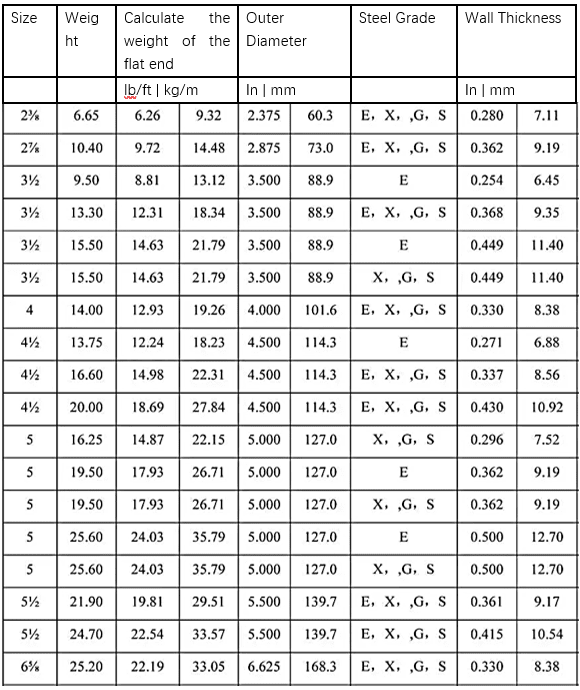

Here are the weight of drill pipe, include: 2 3/8, 2 7/8, 3 1/2, 4, 4 1/2, etc.

Material and process of 2 3/8'' drill pipe

The strength of 2 3/8’’ drill pipe is based on materials and heat treatment process. API

5DP grades commonly used in the industry, such as E75, X95, and G10, achieve

high tensile strength and corrosion resistance by controlling the carbon

content (0.25–0.35%), manganese (1.0–1.8%), and the proportion of elements such as Cr and Mo. With

normalizing or normalizing + tempering heat treatment, the microstructure is

uniform and the toughness is greatly improved.

The finished product production process

includes:

Careful preparation of seamless hot-rolled

tube billets to eliminate internal defects;

Controlled rolling and controlled cooling

to ensure the accuracy of outer diameter and wall thickness;

Quenching and tempering heat treatment to

balance strength and plasticity;

The threaded ends are processed and heat

treated in multiple passes to extend the fatigue life;

Finally, non-destructive testing such as

ultrasonic and magnetic powder is used to ensure the reliable quality of each

pipe.

Main features of 2 3/8'' drill pipe

1. High tensile strength

Meets the strict requirements of tension

for deep wells, horizontal wells, and large-diameter wellbore drilling.

2. Good fatigue resistance

The threaded end design and heat treatment

work together to delay crack propagation and are suitable for long-cycle

operations.

3. Corrosion resistance

Alloy element protection plus surface

coating, combined with appropriate chemical treatment in CO₂ and H₂S environments

can extend service life.

Application scenarios of 2 3/8'' drill pipe

Although 2 3/8" drill pipe is most

commonly used in oil and gas well drilling, its application is not limited to

this, and it has become an important hub for connecting pup joints, casing pipe

and pumping systems:

Geological exploration and core sampling:

fine sampling needs call for small diameters and high precision;

Geothermal energy development: stability

under high temperature and high pressure environments;

Mining engineering and water well drilling:

flexible interface, suitable for various drilling rigs and well types.

Read more: Size of Drill Pipe or How Many Types of Drill Pipe Threads Are There?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.