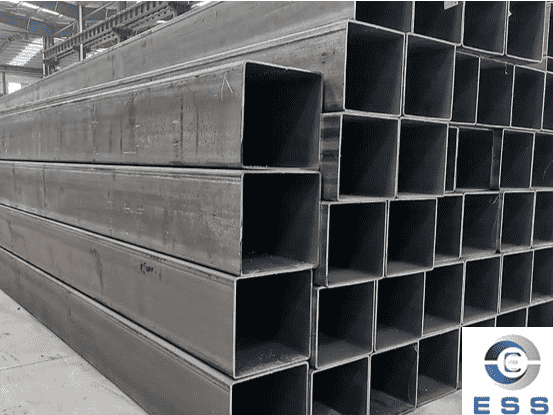

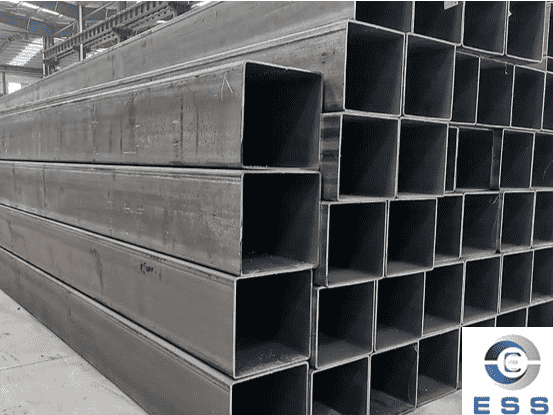

In steel structures, construction

engineering, machinery manufacturing, and steel export quotations, the weight

of square

tube (SHS steel) is a crucial fundamental issue. The weight directly

impacts transportation costs, project costs, and loading schemes, and also

relates to the load-bearing capacity calculation in structural design.

Therefore, mastering accurate, authoritative, and verifiable square tube

weights and calculation methods is essential for purchasers, engineers, and

foreign trade professionals.

Square Tube Weight Calculation

In practical engineering and international

trade, the most commonly used calculation formula is a simplified formula based

on the theoretical density of steel, 7.85 g/cm³.

Commonly used quick calculation formula:

Square Tube Weight (kg/m) ≈ Side Length (mm) × 4 × Wall Thickness (mm) × 7.85 ÷ 1000

This formula applies to:

Ordinary carbon steel square tubes (Q235 /

S235 / ASTM A500, etc.)

The wall

thickness of square tubes is relatively thin (t ≤ 1/10 of the side length)

Suitable for engineering estimation,

quotation, and quick calculation scenarios

Example:

The weight per meter of a 60*60*4mm square

tube is calculated as follows:

(60×4×4)×7.85÷1000=7.02kg/m

(rounded to two decimal places).

Other Factors Affecting Weight

1. Material Differences

Stainless steel has a slightly higher

density (7.93g/cm³) than carbon

steel, making square tubes of the same size heavier. The densities of

square tubes of different materials are as follows:

Carbon steel: 7.85 g/cm³

Stainless steel (304): 7.93–8.00 g/cm³

Aluminum alloy: 2.70 g/cm³

Galvanized steel: 7.85 g/cm³

2. Non-standard Wall Thickness

For example, a 60*60*3.5mm square tube

weighs approximately (60×4×3.5)×7.85÷1000≈6.16kg/m.

EN 10210: ±10%

ASTM A500: ±10%

3. Coating/Painting

Adding a zinc coating or powder coating

will increase the weight by approximately 3%-8%.

Square Tube Weight in KG

Square Tubes Weight Capacity

The material, design, structure, and

installation method of the steel tube all affect its load-bearing capacity.

Therefore, the weight, size, wall thickness, and load-bearing capacity of a

square tube are directly proportional.

|

Size(mm)

|

W.T.(mm)

|

Weight(kg/m)

|

Strength(MPa)

|

Weight Capacity(kg/m)

|

|

20×20

|

1.2

|

0.75

|

235-355

|

50-80

|

|

40×40

|

2

|

2.29

|

235-355

|

120-180

|

|

50×50

|

2.5

|

3.81

|

235-355

|

200-300

|

|

80×80

|

4

|

9.96

|

355-500

|

500-800

|

|

100×100

|

4.5

|

11.65

|

355-500

|

800-1200

|

|

120×120

|

6

|

17.71

|

500-700

|

1500-2000

|

FAQ

1. What is the unit of weight for square

tubes?

Single piece/single meter: kg/m

Bulk: kg/ton

Price: USD/MT or USD/PCS

2. How to calculate the weight of square

tubes of different materials?

Different materials of square tubing have

different densities, therefore different density values need to be used when

calculating weight. For example, the density of stainless steel is 8.0 g/cm³, and the density of

aluminum alloy is 2.7 g/cm³.

Summary

In summary, the essence of weight

calculation is square

tube size × wall thickness × material density. In most engineering and foreign trade scenarios,

the theoretical density of carbon steel (7.85 g/cm³) is

sufficient for pricing, transportation, and cost accounting needs; however, in

structural design, thick-walled square tubing, or high-strength applications,

the complete section formula should be used in conjunction with the specific

steel grade for calculation.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.