Differences Between J55 vs. K55 Oil Casing Pipe

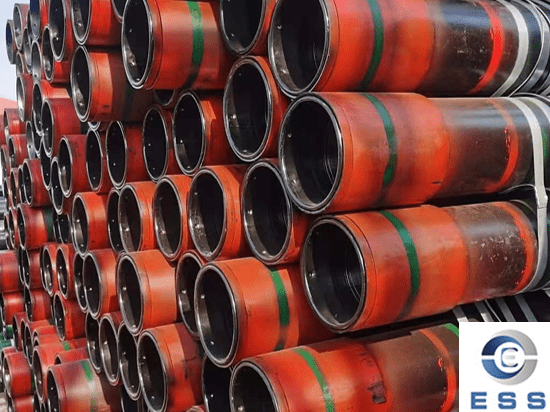

Oil casing pipe is the lifeline of oil well operations. Due to varying geological

conditions, downhole stresses are complex, with tensile, compressive, bending,

and torsional stresses acting on the casing pipe. This places high demands on

the casing pipe's quality. Damage to the casing pipe for any reason can lead to

reduced production or even the loss of the entire well. In corrosive

environments, the casing pipe must also be corrosion-resistant. In areas with

complex geological conditions, it must also be resistant to collapse.

Therefore,

selecting the appropriate steel grade is crucial to ensuring the safe,

efficient, and long-term operation of oil wells. Casing pipe can be categorized

by steel strength, including J55, K55, N80, L80, C90, T95, P110, Q125, and

V150. The steel grade used varies depending on well conditions and depth. J55

and K55 are the most common, so what are the differences between them?

J55 is

one of the most commonly used grades for oil casing pipe and tubing. It offers

medium strength and good toughness, making it well-suited for use in shallow

wells, including oil, gas, and water wells. However, this material is less

suitable for deep well exploration because it cannot withstand high pressures and

temperatures.

K55

grade oil casing pipe and tubing is stronger than J55 while still maintaining

good toughness. K55 tubing and tubing can withstand deep well pressures and

temperatures, making it suitable for oil, gas, and water wells.

API

J55 & K55 Casing Pipe Summary (Specifications, Mass, Wall Thickness, Steel Grade, and Corresponding End Finishes)

|

Size

|

OD

/mm

|

Weight

kg/m

|

WT

t/mm

|

Connection

|

|

|

J55

K55

|

|

|

1

|

2

|

|

|

1

|

2

|

3

|

4

|

5

|

7

|

|

|

4-1/2

4-1/2

4-1/2

4-1/2

4-1/2

|

9.50

10.50

11.60

13.50

15.10

|

114.30

114.30

114.30

114.30

114.30

|

14.38

15.73

17.38

19.87

22.69

|

5.21

5.69

6.35

7.37

8.56

|

PS

PSB

PSLB

-

-

|

|

|

5

5

5

5

5

5

5

|

11.50

13.00

15.00

18.00

21.40

23.20

24.10

|

127.00

127.00

127.00

127.00

127.00

127.00

127.00

|

17.19

19.69

22.69

26.19

32.13

34.76

36.15

|

5.59

6.43

7.52

9.19

11.10

12.14

12.70

|

PS

PSLB

PSLB

-

-

-

-

|

|

|

5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

|

14.00

15.50

17.00

20.00

23.00

26.80

29.70

32.60

35.30

38.00

40.50

43.10

|

139.70

139.70

139.70

139.70

139.70

139.70

139.70

139.70

139.70

139.70

139.70

139.70

|

20.91

23.48

25.72

30.05

34.05

40.15

44.47

48.74

52.80

56.82

60.64

64.41

|

6.20

6.98

7.72

9.17

10.54

12.70

14.27

15.88

17.45

19.05

20.62

22.22

|

PS

PSLB

PSLB

-

-

-

-

-

-

-

-

-

|

|

|

6-5/8

6-5/8

6-5/8

6-5/8

|

20.00

24.00

28.00

32.00

|

168.28

168.28

168.28

168.28

|

29.76

35.72

41.67

47.62

|

7.32

8.94

10.59

12.06

|

-

-

-

-

|

|

|

7

7

7

7

7

7

7

|

17.00

20.00

23.00

26.00

29.00

32.00

35.00

|

177.80

177.80

177.80

177.80

177.80

177.80

177.80

|

25.60

29.91

34.67

39.14

43.60

47.92

52.09

|

5.87

6.91

8.05

9.19

10.36

11.51

12.65

|

-

PS

PSLB

PSLB

-

-

-

|

|

|

7

7

7

7

7

7

|

38.00

42.70

46.40

50.10

53.60

57.10

|

177.80

177.80

177.80

177.80

177.80

177.80

|

56.10

63.84

69.35

74.85

80.21

85.42

|

13.72

15.88

17.45

19.05

20.62

22.22

|

-

-

-

-

-

-

|

|

|

7-5/8

7-5/8

7-5/8

7-5/8

7-5/8

7-5/8

7-5/8

7-5/8

7-5/8

7-5/8

|

24.00

26.40

29.70

33.70

39.00

42.80

45.30

47.10

51.20

55.30

|

193.68

193.68

193.68

193.68

193.68

193.68

193.68

193.68

193.68

193.68

|

35.72

39.29

44.20

50.15

58.04

63.69

67.41

70.09

76.19

82.30

|

7.62

8.33

9.52

10.92

12.70

14.27

15.11

15.88

17.45

19.05

|

-

PSLB

-

-

-

-

-

-

-

-

|

|

|

7-3/4

|

46.10

|

196.85

|

68.60

|

15.11

|

-

|

|

|

8-5/8

8-5/8

8-5/8

8-5/8

8-5/8

8-5/8

8-5/8

|

24.00

28.00

32.00

36.00

40.00

44.00

49.00

|

219.08

219.08

219.08

219.08

219.08

219.08

219.08

|

35.72

41.67

47.62

53.57

59.53

65.48

72.92

|

6.71

7.72

8.94

10.16

11.43

12.70

14.15

|

PS

-

PSLB

PSLB

-

-

-

|

|

|

9-5/8

9-5/8

9-5/8

9-5/8

9-5/8

9-5/8

9-5/8

9-5/8

9-5/8

9-5/8

9-5/8

|

32.30

36.00

40.00

43.50

47.00

53.50

58.40

59.40

64.90

70.30

75.60

|

244.48

244.48

244.48

244.48

244.48

244.48

244.48

244.48

244.48

244.48

244.48

|

48.07

53.57

59.53

64.73

69.94

79.62

86.91

88.40

96.58

104.62

112.50

|

7.92

8.94

10.03

11.05

11.99

13.84

15.11

15.47

17.07

18.64

20.24

|

-

PSLB

PSLB

-

-

-

-

-

-

-

-

|

|

|

10-3/4

10-3/4

10-3/4

10-3/4

10-3/4

10-3/4

10-3/4

|

32.75

40.50

45.50

51.00

55.50

60.70

65.70

|

273.05

273.05

273.05

273.05

273.05

273.05

273.05

|

48.74

60.27

67.71

75.90

82.59

90.33

97.77

|

7.09

8.89

10.16

11.43

12.57

13.84

15.11

|

-

PSB

PSB

PSB

PSB

-

-

|

|

|

10-3/4

10-3/4

10-3/4

|

73.20

79.20

85.30

|

273.05

273.05

273.05

|

108.93

117.86

126.94

|

17.07

18.64

20.24

|

-

-

-

|

|

|

11-3/4

11-3/4

11-3/4

11-3/4

11-3/4

11-3/4

|

42.00

47.00

54.00

60.00

65.00

71.00

|

298.45

298.45

298.45

298.45

298.45

298.45

|

62.50

69.94

80.36

89.29

96.73

105.66

|

8.46

9.53

11.05

12.42

13.56

14.78

|

PSB

PSB

PSB

PSB

-

-

|

|

|

13-3/8

13-3/8

13-3/8

13-3/8

13-3/8

|

48.00

54.50

61.00

68.00

72.00

|

339.72

339.72

339.72

339.72

339.72

|

71.43

81.10

90.78

101.19

107.15

|

8.38

9.65

10.92

12.19

13.06

|

-

PSB

PSB

PSB

-

|

|

|

16

16

16

16

|

65.00

75.00

84.00

109.00

|

406.40

406.40

406.40

406.40

|

96.73

111.61

125.01

162.21

|

9.53

11.13

12.57

16.66

|

-

PSB

PSB

P

|

|

|

18-5/8

|

87.50

|

473.08

|

130.21

|

11.05

|

PSB

|

|

|

20

20

20

|

94.00

106.50

133.00

|

508.00

508.00

508.00

|

139.89

158.49

197.93

|

11.13

12.70

16.13

|

PSLB

PSLB

PSLB

|

|

|

Notes: P: Plain End; S: Short Round

Thread; L: Long Round Thread; B: Trapezoidal Thread; Polar Line

|

|

|

a: The nominal mass per unit length

(column 4) shown is for reference only.

b: Martensitic chromium steels (L80-9Cr

and 13Cr) have densities different from carbon steels. The masses shown are

not exact values for martensitic chromium steels. A mass correction factor of

0.989 may be used.

c. For casing pipe with S, L, or B

threads, intermediate wall thicknesses are permitted in accordance with

Sections 5.2.3 and 8.2 of this standard and the requirements of API 5B.

|

|

Standard

Requirements for API 5CT Oil Casing Pipe And Tubing: J55 vs. K55

1.

Heat Treatment (Different Between PSL2 and PSL1)

PSL1

Requirements: J55 and K55 are treated the same (can be delivered as-rolled).

PSL2

Requirements: J55 casing pipe and K55 casing pipe should be normalized or normalized and

tempered throughout. If thickened, normalized or normalized and tempered after

thickening.

2.

Straightening (no difference)

3.

Chemical Composition (no difference in control)

4.

Tensile Test (minimum tensile strength varies)

J55:

Yield strength 379MPa-552MPa; tensile strength ≥ 517MPa;

K55:

Yield strength 379MPa-552MPa; tensile strength ≥ 655MPa;

Due to

the difference in tensile strength, the required minimum elongation for J55 is

19% and for K55 is 15%.

5.

Impact Test (difference between PSL2 and PSL1)

Pipe

Body: PSL1 J55 and K55 have no requirements;

PSL2

J55 and K55 require a minimum transverse impact energy of 20J for full-size

specimens and a minimum longitudinal impact energy of 27J for full-size

specimens.

Couplings:

Impact testing is mandatory for J55 and K55, with a minimum transverse impact

energy of 20J for full-size specimens and a minimum longitudinal impact energy

of 27J for full-size specimens.

6.

Hydrostatic test (no difference)

7.

Wall thickness detection (PSL2 and PSL1 are different)

PSL1:

There is no measurement coverage requirement for J55 and K55 wall thickness;

PSL2:

The wall thickness measurement and recording of J55 and K55 should be carried

out over the entire length, and the surface area covered by the automatic

detection system should preferably reach 25%.

8.

Nondestructive testing (PSL2 and PSL1 are different)

PSL1:

There is no mandatory requirement for nondestructive testing of J55 and K55

steel grade casing pipe;

PSL2

All casing pipes of J55 and K55 steel grades should be inspected by one or more

methods specified in standard 10.15.5 to find out the longitudinal defects of

the outer and inner surfaces of the steel pipe that can accept the horizontal

L4.

9.

Identification (different color bands)

J55

steel grade pipe body is sprayed with a bright green band, the coupling is

sprayed with bright green, and a white band is added on it;

K55

steel grade pipe body is sprayed with two bright green bands, the coupling is

sprayed with bright green, and there is no additional color band.

Summary

Oil

casing pipe is an indispensable pipeline equipment in the oil industry. Its

main function is to protect the oil pipe and drill pipe in the oil well. J55 steel grade oil casing pipe has lower strength

and is suitable for shallower well depths and more stable bottom conditions.

Because of its relatively low price, it is often used in some initial

exploration wells and test wells. K55 steel grade oil casing pipe is slightly

higher in strength than J55, and has better corrosion resistance, which is

suitable for more stable bottom environment. Compared with J55, K55 has better

tensile strength and corrosion resistance, and is more suitable for deep well

operations.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.