In large-scale industrial projects (such as

oil and gas, petrochemical, power plants, boilers, and high-rise building

structures), the quality of the seamless

steel pipe directly affects safety, lifespan, and project costs.

When purchasing seamless steel pipes, you

will typically receive a Certificate of Conformity (MTC) issued by the factory.

This document is the Material Test Report (MTR). It is not only a test document

but also the "birth certificate" of the steel pipe, used to verify

whether the product meets industry standards (such as API 5L, ASTM A106,

or EN

10210) and the requirements of specific projects.

For engineers, quality control (QC)

professionals, and purchasing teams, mastering the interpretation of MTCs is

crucial—it ensures compliance, avoids high rework

costs, and guarantees project safety.

What is MTC Certification?

MTC (Mill Test Certificate) certification is a quality certificate

issued by the metal material manufacturer or a third-party testing

organization, detailing the chemical composition, mechanical properties, and

compliant standard requirements of the batch of materials. It is an important

basis for material quality traceability and compliance acceptance, and is

widely used in the fields of steel, pipes, flanges, and pressure vessels.

According to the international standard EN

10204, MTC reports are divided into four types: 2.1, 2.2, 3.1, and 3.2. Types

3.1 and 3.2 provide the most professional certification data and offer the most

reliable evidence for determining the authenticity and quality of materials.

2.1: Non-specific inspection report issued

by the supplier (no test data), suitable for low-risk general steel.

2.2: Report containing routine test

results, for general structural steel.

3.1 (Most commonly used): Material data

report issued by authorized inspectors of the manufacturer, showing formal

testing results, suitable for pressure pipelines, boilers, and the oil and gas

industry.

3.2 (Highest level): Joint certification by

the manufacturer and third-party organizations (such as TUV, BV, LR), suitable

for high-risk projects: nuclear power, subsea pipelines, and high-pressure

vessels.

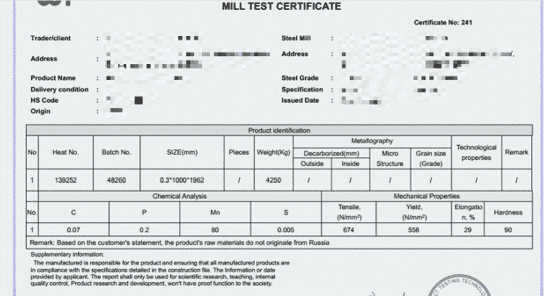

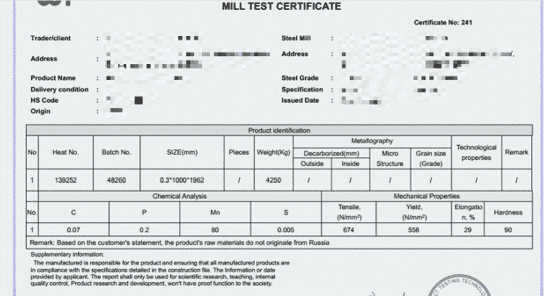

What is the Core Structure of An MTC Report?

Although the format varies slightly among

steel mills, most MTC reports include four non-negotiable parts. Skipping any

of these parts can lead to misunderstandings:

|

Section

|

Key

Content

|

Core

Application Logic

|

|

Header

Information

|

Pipe

mill name, contact details, MTC number, date of issue, and customer name.

|

Links

the certificate to a specific order/batch (critical for traceability).

|

|

Product

Identification

|

Seamless

steel pipe sizes (OD × wall thickness), specifications (e.g., API

5L X65), heat number, and quantity.

|

Confirms

the certificate matches the pipes you received (avoid mix-ups).

|

|

Test

Results

|

Chemical

composition, mechanical properties, and additional tests (e.g., NDT,

hydrostatic testing).

|

Proves

the pipe meets standard/ project requirements.

|

|

Certification

|

Signature

of the mill’s authorized representative, and (if required) accreditation from

a third-party body

|

Validates

the accuracy and authenticity of the test results.

|

Verify the Heat Number on the Seamless

Steel Pipe's MTC

Develop the good habit of carefully

checking that the heat number (a unique identifier for the metal batch) on the

Metal Testing Certificate (MTC) matches the heat number engraved on the

seamless steel pipe.

Check:

The Heat No. on the MTC

The Heat No. on the steel stamp/inkjet

marking on the outer wall of the pipe

The Heat No. on the mill's Packing List

If a discrepancy is found, it indicates a

problem with the product material. The factory should be contacted immediately

to follow up, identify the cause, and develop a solution to minimize the

adverse effects of the error.

Understanding the Chemical Composition

in the Seamless Steel Pipe's MTC

The "Chemical Composition"

section lists the percentages of elements such as carbon, manganese, and

chromium in the seamless steel pipe. These factors directly affect the

strength, corrosion resistance, and weldability of the steel pipe. Here's how

to interpret it:

Step 1: Identify the "Elements"

and "Values" columns.

Common indicators include:

Carbon (C): Higher carbon content results

in stronger corrosion resistance, but excessive carbon content can reduce

weldability. In the API 5L X65 standard, the upper limit for carbon content is

typically 0.22%.

Manganese (Mn): Improves toughness and

corrosion resistance. ASTM A106 Class B (a commonly used seamless steel pipe

for pressure applications) requires a manganese content between 0.27% and

0.93%.

Phosphorus (P) and Sulfur (S): Considered

"impurities"—excessive content can cause the

steel pipe to become brittle. Most standards limit the content of phosphorus

and sulfur to 0.035% or less.

To improve the corrosion resistance of

pipes, alloying elements are added. For example, in the ASTM A335 P91 standard,

chromium (Cr: 8.0-10.5%) and molybdenum (Mo: 0.85-1.05%) are added to resist

high temperatures and harsh environments.

Step 2: Compare the results with your own

standards.

Don't just look at the numbers; compare

them to applicable standards or project specifications.

For example, if your project requires the

use of API 5L X70 seamless steel pipe with a carbon content ≤ 0.20% (according to API 5L PSL2 standard), then a result of 0.23%

indicates that the pipe does not meet the standard, even if it is very close.

When steel pipes are used in seawater, the

sulfur content can be adjusted to improve corrosion resistance.

Typically, the sulfur content is reduced.

The content is within this range (≤0.035% vs. ≤0.035%). 0.025% is optimal. When specifying a particular component

content ratio, this custom requirement must be reflected in the MTC (Mechanical

Properties Test).

Understanding the Mechanical Properties

in Seamless Steel Pipe MTC

The "Mechanical Properties"

indicator is a crucial factor in measuring the performance of seamless steel

pipes under pressure. This indicator is critical for projects involving

pressure, weight, or temperature fluctuations. A deeper understanding of this

indicator will benefit project management. Please focus on the following three

key indicators.

|

Metric

|

Definition

|

How

to Use It

|

|

Yield

Strength (YS)

|

The

stress at which the pipe begins to deform permanently.

|

For

high-pressure oil pipelines (API 5L X65), YS must be ≥448 MPa. If the MTC

shows 430 MPa, the pipe can’t handle the design pressure.

|

|

Tensile

Strength (TS)

|

The

maximum stress the pipe can withstand before breaking.

|

TS

is often paired with YS—API 5L X65 requires TS ≥535 MPa. A TS/YS ratio

<1.2 indicates poor ductility (risk of brittle failure).

|

|

Elongation

|

The

percentage the pipe stretches before breaking (measures ductility).

|

ASTM

A106 Grade B requires ≥30% elongation. Low elongation (e.g., 25%) means the

pipe may crack under sudden pressure changes.

|

Professional Tip:

Pay Attention to "Average" vs.

"Minimum".

Some steel mills report the

"average" mechanical properties of a batch of steel pipes, but

standards usually require each pipe to meet the minimum value.

For example, if the Material Testing

Certificate (MTC) shows "average pressure: 450 MPa," but the API 5L

X65 standard requires a minimum pressure of 448 MPa for each pipe, individual

test results are needed—a single poorly performing pipe

could jeopardize the entire system.

Common Additional Tests in MTC

Hydrostatic Test: Checks pipe sealing.

NTD (UT/ET) Non-destructive Testing: Checks

for cracks/inclusions.

Impact Test (Charpy V-notch):

Low-temperature toughness (e.g., -20°C).

Dimensional Tolerance Testing: Outer

diameter/wall thickness/ovality.

Hardness Testing (HB/HRC): Determines

brittleness and heat treatment quality.

Why is MTC Important for Seamless Steel

Pipes?

A Material Testing Certificate (MTC) is

more than just a document; it's the foundation of a project's Quality Assurance

(QA) program. Here are the reasons why an MTC is indispensable:

1. Preventing Non-Conforming Materials from

Entering the Site

Without an MTC, it's impossible to prove

that seamless steel pipes meet specifications.

For example, mistaking ASTM A53B pipe (low pressure) for A106B pipe (high pressure steam).

2. Promoting Regulatory and Safety

Compliance

Most industries (oil and gas, nuclear,

etc.) have stringent regulations requiring documentation of material quality.

In the United States, the Piping and

Hazardous Materials Safety Administration (P

HMSA) mandates that all pipelines

transporting hazardous fluids must obtain MTC certification.

3. Ensuring Traceability of Failure Sources

If a problem occurs with seamless steel

pipes (such as pressure cracking), an MTC (Mechanical Traceability Inspection)

can help determine the root cause.

In the event of cracks or pipe bursts, the

MTC can quickly pinpoint the furnace responsible.

4. Production Guidance

Provides key chemical composition and

mechanical property parameters for subsequent processing (such as welding, heat

treatment, and cold bending).

5. Dispute Resolution

When questions arise about material quality

or quality incidents occur, the MTC report serves as primary verification and

legal evidence.

How to Verify the Authenticity of MTC

Certification for Seamless Steel Pipes?

1. Verify Certificate Information

Check if the manufacturer's name and

address match the contract information.

Verify that the batch number matches the

physical identification (such as stamps and labels).

2. Compare Test Data

Compare the chemical composition with

standard requirements to determine if it is within the allowable range.

Check if the mechanical properties match

the material grade reasonably.

3. Confirm Certificate Type

For high-risk projects, it is recommended

to choose MTC 3.1 or 3.2 certification to ensure data accuracy.

4. Verify Third-Party Witnessing

If the certificate indicates a third-party

organization (such as TUV, BV), verify with their official channels.

5. Anti-counterfeiting Technology

Inspection

Some manufacturers add QR codes and

anti-counterfeiting codes to the MTC (Mill Test Certificate), which can be

verified directly online.

FAQ

1. Is a Mill Test Certificate mandatory for

seamless steel pipes?

In most oil and gas, pressure pipelines,

boilers, and power engineering projects, the MTC is a mandatory document.

It is not mandatory in general building

structures, but it is still recommended to provide it to ensure traceability.

2. What is the mill tolerance for seamless

pipes?

The rolling tolerance for seamless steel

pipes is typically ±12.5%, as specified by mainstream

standards such as API 5L, ASTM A106, and ASTM A53.

Conclusion

The MTC (Mill Test Certificate) serves as

an important proof of material quality. It not only verifies whether the metal

material meets standards but also effectively prevents counterfeit and

substandard products from entering the market. Interpreting a seamless steel

pipe material inspection certificate involves verifying the consistency of the

heat number, ensuring that the chemical composition and mechanical properties

meet specifications, and confirming that the testing has been completed. If any

questions arise—such as a missing signature or values that are

"close but not acceptable"—please contact the steel mill immediately.

Read more: Latest Top 6 Seamless Steel Pipe Manufacturers in China

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.