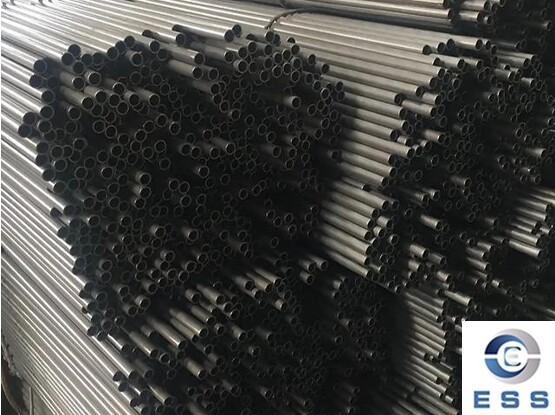

Black steel pipes are steel pipes whose surface has not been

galvanized. Unlike galvanized steel pipes, their surface

does not have any coating. Generally, black steel pipes are treated with rust

prevention. The materials of seamless black steel pipes mainly include ordinary

carbon steel, low-alloy structural steel and alloy steel. After processing,

these materials are directly cold-drawn into seamless steel pipes without any

solution heat treatment, which have high strength, reliability and good

machinability. Mild steel pipe is widely used

in this category, especially for projects requiring toughness and weldability.

Seamless black steel pipes implement international standards such as

GB/T8162-2018 and ASTM A106, and have an irreplaceable position in key fields

such as petrochemicals and machinery manufacturing.

Manufacturing process of seamless black steel pipes

The manufacturing process of seamless black steel pipes is relatively

complicated. First, the billet needs to be heated to an appropriate

temperature, and then pierced through a piercing machine to form a tube billet.

Next, the tube billet will be rolled by a tube rolling mill to form a seamless pipe. Finally, after

heat treatment, straightening, cutting and other processes, high-quality

seamless black steel pipes are finally produced.

Characteristics of seamless black steel pipes

1. High strength

Seamless black steel pipes have undergone special production processes

and have high compressive strength and tensile strength, and can withstand

greater pressure and load.

2. Corrosion resistance

The surface of seamless black steel pipes has been specially treated

and has good corrosion resistance, suitable for various harsh environments.

3. Smooth and seamless

The inner and outer walls of seamless black steel pipes are smooth and

seamless, which reduces the resistance of the fluid in the pipeline and

improves the transportation efficiency.

Core material system analysis

1. Carbon steel series

20# steel (C content 0.17%-0.23%): basic general-purpose material,

suitable for medium and low pressure fluid transportation.

45# steel (C content 0.42%-0.50%): high-strength structural steel,

tensile strength ≥600MPa.

2. Low alloy structural steel

Q345B (16Mn): Add 1.2%-1.6% manganese, and the yield strength is

increased by 40%.

ASTM A335 P11: Contains 1.0% chromium-0.5% molybdenum, and the

temperature resistance can reach 550℃.

3. Special alloy steel

304L stainless steel (00Cr19Ni10): Ultra-low carbon design,

intergranular corrosion resistance increased by 30%.

Duplex steel 2205 (S31803): Ferrite-austenite dual-phase structure,

excellent chloride ion corrosion resistance.

|

Comparison of

key performance indicators

|

|

Performance parameters

|

Carbon steel

|

Low alloy steel

|

Alloy steel

|

|

Tensile strength (MPa)

|

410-530

|

550-700

|

750-900

|

|

Yield strength (MPa)

|

245-310

|

345-460

|

520-690

|

|

Elongation (%)

|

≥25

|

≥18

|

≥15

|

|

Impact energy (J, -20℃)

|

≥34

|

≥45

|

≥60

|

|

Corrosion resistance grade

|

C3

|

C4

|

C5-M

|

Application areas of seamless black steel pipes

1. Oil and gas transportation

Seamless black steel pipes are widely used in long-distance oil and gas

transportation pipelines, such as casing pipe systems, due to

their high strength and corrosion resistance.

2. Mechanical engineering

In the field of mechanical engineering, seamless black steel pipes are

often used to manufacture various mechanical parts and structural parts, such

as bearings, cylinders, etc.

3. Chemical and pharmaceutical industries

Since seamless black steel pipes have good corrosion resistance, they

are also widely used in the production processes of the chemical and

pharmaceutical industries.

Summary

In short, seamless black steel pipes have become an indispensable and

important material in modern industry due to their excellent material

properties and wide application fields. By selecting appropriate materials and

specifications, we can better meet production needs and improve product

quality, and promote the sustainable development of the industry.

Read more: Differences between seamless black steel pipe and black iron pipe

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.