What Are The Applications of Well Casing Pipe?

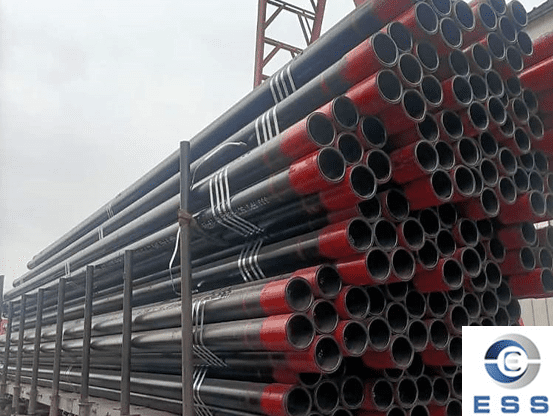

Well casing pipe is a steel pipe structure

installed inside the wellbore and is widely used in oil production, groundwater

extraction, and geological exploration. Its primary functions are to support

the wellbore wall, isolate the formation, prevent fluid cross-linking, and

provide a channel for various downhole operations. Proper use of well casing

pipe can significantly improve well safety, stability, and operational

efficiency. So, what are its main applications?

Well casing pipe in oil production

In the oil and gas industry, well casing

pipe is a core component of oil country tubular goods (OCTG) and is

typically manufactured in accordance with API Spec 5CT.

Its application value is reflected in the following aspects:

1. Oil well protection and support

During oil production, oil well casing pipe

is a key component for protecting the wellbore wall.

Once the drill bit reaches a certain depth,

well casing pipe is lowered into the wellbore to prevent wellbore collapse.

During oil production, wellbore collapse can occur due to various factors, such

as formation pressure, rock properties, and drilling fluid erosion.

In some oil wells located in soft or

fractured formations, well casing pipe provides essential support to maintain

wellbore stability and ensure smooth subsequent production operations.

2. Isolating different formations

The geological conditions and fluid

properties of different formations vary significantly, and oil production often

traverses multiple formations (such as aquifers, oil layers, and gas layers).

Casing pipe's isolation function can:

Prevent fluid cross-contamination between

formations, preventing water intrusion into oil layers or gas channeling;

Prevent oil and gas leakage into non-target

layers, improving production efficiency;

Facilitate stratified water injection and

oil recovery, achieving refined reservoir management.

3. Guiding drilling tools and equipment

Well casing pipe provides guidance for the

lowering and extraction of drilling tools (such as drill pipe and logging instruments), allowing them to safely operate along a predetermined

path within the well.

This guidance function is particularly

important in deep wells or wells located in complex formations. It reduces

collision and friction between tools and the wellbore wall, extending tool life

and improving the accuracy of drilling and logging operations.

Well casing pipe in groundwater extraction

Well casing pipe is not only used in the

oil and gas industry but is also indispensable in groundwater projects

(drinking water wells, agricultural irrigation wells, geothermal wells, etc.).

1. Preventing well collapse and

contamination

For groundwater wells, water well casing pipe

prevents soil particles from surrounding the well wall from falling into the

well, thus preventing well wall collapse.

It also acts as a barrier, preventing

surface pollutants (such as sewage and pesticides) from seeping into the

groundwater, thereby protecting groundwater quality.

For example, in rural drinking water wells,

well casing pipe ensures that the extracted groundwater is clean and

contaminant-free, thus ensuring the safety of drinking water for residents.

2. Improving water extraction efficiency

and quality

Appropriate water well casing pipe can optimize

the groundwater inflow path, ensuring smoother groundwater flow into the well.

By rationally designing parameters such as

the well casing pipe diameter, length, and pore structure, the contact area

between the groundwater and the casing pipe can be increased, improving water

extraction efficiency.

In addition, water well casing pipe prevents

large amounts of impurities such as silt from entering the well, thereby

improving water quality.

Well casing pipe in geological

exploration

Well casing pipe also plays a vital role in

mineral exploration and scientific drilling.

1. Maintaining borehole integrity

Casing pipe supports the borehole,

preventing deformation and collapse of the wellbore wall due to formation

fracture or high-pressure infiltration;

It also ensures the integrity of core

collection, providing accurate data for stratigraphic correlation and mineral

evaluation.

2. Assisting geological testing and monitoring

Well casing pipe facilitates the

installation of various geological testing instruments (such as pressure

sensors and temperature sensors).

These instruments can be lowered into the

wellbore through the casing pipe to monitor formation pressure, temperature,

fluid properties, and other characteristics in real time, helping geologists

better understand the underground geological structure and resource

distribution.

Materials and standards for well casing

pipe in different fields

|

Application

|

Common Materials

|

Standards/Specifications

|

|

Petroleum Extraction

|

Carbon Steel Casing pipe (API Grades such

as J55,

K55, N80,

L80, and P110)

|

API Spec 5CT, ISO 11960, and API RP 65

|

|

Groundwater Extraction

|

Carbon Steel, Stainless Steel, PVC, and

Fiberglass

|

ASTM F480, ISO 14686, and local

groundwater well construction specifications

|

|

Geological Exploration

|

Carbon Steel, Stainless Steel, and PVC

|

Pipe ASTM D5783 and national/local

geological exploration specifications

|

Summary

Well casing pipe plays a crucial role in

oil extraction, groundwater utilization, and geological exploration. It plays

an irreplaceable role in wellbore stability and safety: it is the

"skeleton" of wellbore stability and safety; it is the key to

controlling formation fluids and ensuring recovery rate; and it is also an

important tool for scientific exploration and environmental protection.

Read more: Water Well Casing Pipe Specifications

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.