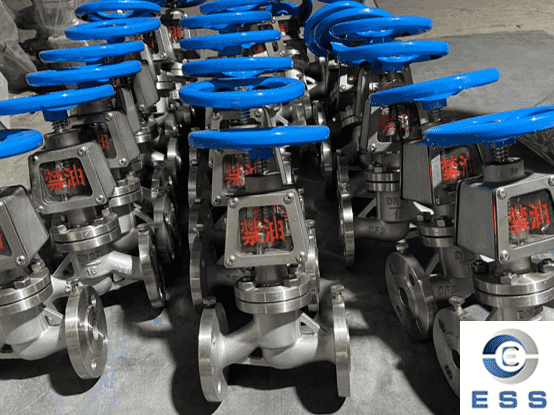

The globe valve is a main valve used in water, oil, gas and other pipeline systems. The flow of

the medium is controlled by opening and closing the valve. The main features of

the globe valve are good sealing, small pressure loss, simple structure, and

easy maintenance. Before use, you should ask the valve manufacturers for detailed instructions on use to avoid incorrect use and reduce work

efficiency. For example, in most cases, the globe valve is designed so that the

fluid enters from the bottom and flows out from the top. Why is this?

Reasons for low inlet and high outlet

The globe valve is generally installed in

the pipeline. In order to ensure that the flow of the fluid in the pipeline is

not affected, it is generally low inlet and high outlet.

1. Ensure the stability of the system

The globe valve has a low inlet and a high

outlet to ensure the stable flow of the fluid in the pipeline. Since the liquid

is denser than the gas, the liquid will be affected by gravity when it moves in

the pipeline, and the resistance will also increase, thereby increasing the

pressure loss of the fluid. Letting the globe valve have a low inlet and a high

outlet can reduce the flow resistance of the fluid, reduce pressure loss, and

ensure the stability of the system.

2. Prevent air and impurities from entering

the pipeline

The globe valve has a low inlet and a high

outlet and can also effectively prevent air and impurities from entering the

pipeline. When the pipeline system fails or shuts down for maintenance, there

will be a certain pressure difference in the pipeline. If the valve position is

reversed, the gas and impurities in the pipeline will enter the pipeline,

affecting the normal operation of the pipeline.

3. Convenient installation and maintenance

The low-inlet and high-outlet globe valve

can be easily installed and maintained. During installation, the low-position

valve is generally installed first, and then the high-position valve is

installed, which can facilitate installation and maintenance and reduce risks

and costs.

High-inlet and low-out in special cases

In some special cases, the globe valve will

also adopt a high-inlet and low-out design. For example, for high-pressure

globe valves with a diameter greater than 100 mm, due to the poor sealing

performance of large-diameter valves, the high-inlet and low-out design can

increase the sealing of the valve in the closed state. In addition, in the two

globe valves in series on the bypass pipeline, the second globe valve usually

adopts a high-inlet and low-out design to ensure the tightness of the valve

within a maintenance cycle, especially in valves that require frequent opening

and closing operations.

Summary

The globe valve is an important control

valve in the pipeline system. The installation method of the globe valve with

low inlet and high outlet can effectively ensure the stable flow of fluid in

the pipeline and prevent air and impurities from entering the pipeline. It also

facilitates the installation and maintenance of the globe valve. Therefore,

when using the globe valve in the pipeline system, you must pay attention to

its installation method of low inlet and high outlet.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.