The material of the casing pipe pup joint has a crucial impact on its performance and service life. The material

selection of the casing pipe pup joint should be determined according to the

needs of the specific application scenario to ensure its excellent performance

during use and extend its service life.

When choosing the material of the casing

pipe pup joint, the following main factors need to be considered:

1. Corrosion resistance: The

casing pipe pup joint needs to be able to maintain its performance in various

environments and not be corroded. Common corrosion-resistant materials include

stainless steel (such as 304 and 316L stainless steel) and plastics (such as PVC,

PE, etc.).

2. High temperature resistance: If the

casing pipe pup joint needs to be used in a high temperature environment, a

material with good high temperature resistance should be selected. For example,

materials such as alkali-free glass fiber, silicone rubber and ceramic fiber

can remain stable at high temperatures.

3. Flame retardant performance: For

occasions where fire protection is required, it is very important to choose a

material with good flame retardant performance. Materials such as alkali-free

glass fiber, silicone rubber and ceramic fiber have good flame retardant

properties.

4. Insulation performance: If the

casing pipe pup joint is used in an electrical system, insulation performance

is key. PVC-U electrical conduit has good insulation performance and is

suitable for electrical systems.

5. Cost and budget: The

prices of different materials vary greatly, and it is necessary to choose the

right material according to the budget. For example, PVC material has a lower

cost, while stainless steel material has a higher cost.

Advantages and disadvantages of different materials:

1. PVC material: It has good insulation

performance and wear resistance, low cost, but poor high temperature

resistance.

2. PE material: It has good flexibility and

insulation, but its high temperature resistance is not as good as PVC.

3. Galvanized

steel pipe: It has good conductivity and durability, and is suitable for high

current environments, but the cost is high.

4. Stainless steel: It has

good corrosion resistance and strength, and is suitable for special

environments, but the cost is high.

5. Alkali-free glass fiber: It has

good high temperature resistance and flame retardant properties, but the cost

is high.

6. Silicone rubber: It has

high temperature resistance and good insulation, but the cost is high.

7. Ceramic fiber: Excellent fire resistance and heat insulation, but the cost is

high.

Application scenarios and specific

selection recommendations:

1.

Electrical system: Choose

PVC-U electrical conduit because it has good insulation performance and low

cost.

2. High

temperature environment: Choose alkali-free glass fiber, silicone rubber or ceramic fiber,

which can remain stable at high temperatures.

3. Corrosive environment: Choose

stainless steel or plastic materials to prevent corrosion.

4. Environment with high fire protection requirements: Choose alkali-free glass fiber, silicone rubber or ceramic fiber,

which have good flame retardant properties.

Summary

In summary, when choosing the material of the casing pipe short

section, it is necessary to determine it according to the specific use

environment and needs, and comprehensively consider factors such as corrosion

resistance, high temperature resistance, flame retardant performance,

insulation performance and cost to ensure the maximum benefit of the short

section performance.

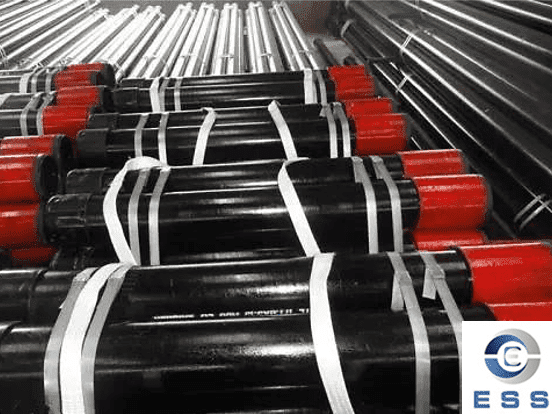

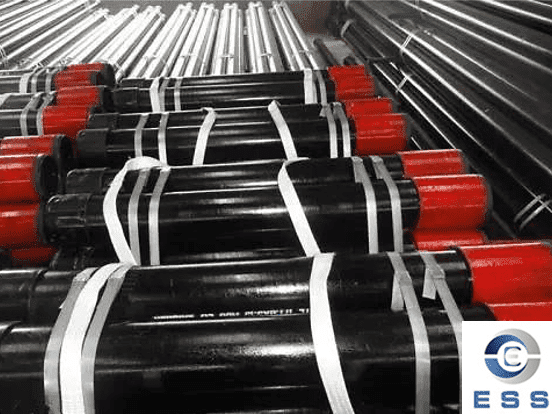

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.