Square tube is a common structural material in industrial and construction

fields, and the choice of material directly affects the safety, durability, and

cost-effectiveness of a project. Different square tube materials vary

significantly in mechanical properties, corrosion resistance, and processing

technology. Therefore, a targeted selection must be made based on the specific

application scenario (such as machinery manufacturing, building framing, and

decoration engineering). In the fields of building engineering, machinery

manufacturing, energy equipment, and industrial support, square tubes are an

extremely common structural profile. For purchasing managers, engineers, and

project contractors, choosing the right square tube material not only

determines structural safety and service life but also directly impacts the

total project cost, maintenance expenses, and delivery cycle.

Based on international engineering practice

and export project experience, the mainstream square tube materials mainly fall

into three categories: carbon steel square tubes, stainless steel square tubes,

and aluminum alloy square tubes. This article will systematically compare them

from the dimensions of mechanical properties, corrosion resistance, processing

and installation, application scenarios, and overall cost-effectiveness to help

you quickly make a business decision that meets your project needs.

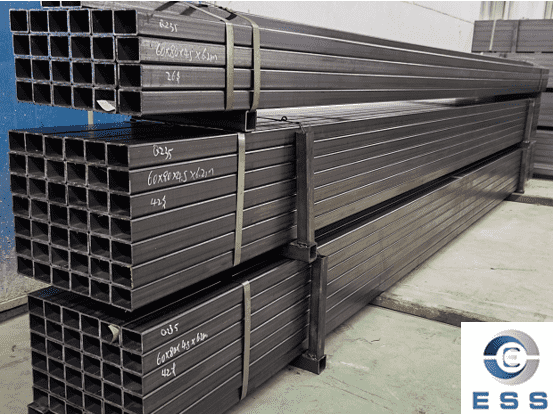

Carbon Steel Square Tube: The Most

Cost-Effective Structural Choice

Carbon steel square tube is currently the

most widely used type of material. Its main components are iron and carbon.

Based on carbon content and strength, it can be divided into ordinary carbon

steel and high-strength carbon steel. Common grades include EN S235/S355.

1. Advantages of Carbon Steel Square Tube

High strength (S355 tensile strength

reaches 470-630MPa), good rigidity, low price (approximately 3000-5000

RMB/ton), easy to weld and cut, and highly convenient to process.

2. Disadvantages of Carbon Steel Square Tube

Poor corrosion resistance; prone to rusting in humid, outdoor, or

chemically corrosive environments, requiring additional anti-corrosion

treatment; heavier than aluminum alloys and plastics (density approximately

7.85g/cm³).

3. Applicable Scenarios for Carbon Steel

Square Tube

Building structures: such as columns/beams

of steel structure factories, scaffolding, curtain wall support frames, and

stair handrail skeletons.

Mechanical Manufacturing: Such as equipment

bases, conveyor frames, machine tool supports (relying on their high strength

and low cost).

Civilian Applications: Such as clothes rack

supports, security window frames (requiring painting or galvanizing for

corrosion protection).

If your project prioritizes load-bearing

capacity and cost control, and environmental corrosion risks are manageable,

carbon steel square tube remains the optimal solution.

Stainless Steel Square Tube: The First

Choice for Corrosion Resistance and Quality Projects

The core advantage of stainless steel square

tube is its corrosion resistance, primarily due to the oxide film formed by

chromium (Cr≥12%) and nickel (Ni) elements in the

material, isolating it from external corrosion.

1. Core Performance of Stainless Steel Square

Tube (Comparison by Material)

304 Stainless Steel: Resistant to air,

water, and weak acids and alkalis (such as rainwater and tap water), not

resistant to strong salt spray (such as at the seaside), easy to weld and

polish.

316 Stainless Steel: Resistant to strong

corrosion (salt spray, seawater, chemical solutions), contains molybdenum (Mo)

to improve corrosion resistance, slightly less machinable than 304.

2. Advantages of Stainless Steel Square

Tube

Excellent corrosion resistance; service

life 2-3 times that of carbon steel square tubes.

High hygiene standards, meeting the

requirements of the food and pharmaceutical industries.

High-end appearance; brushed and

mirror-polished finishes are available.

Low maintenance costs; virtually no

post-contamination protection required.

3. Disadvantages of Stainless Steel Square

Tube

High procurement cost (typically 2-4 times

that of carbon steel square tubes).

High material density, hindering

lightweight design.

4. Applicable Scenarios for Stainless Steel

Square Tubes

304 Stainless Steel Square Tubes: Food

processing equipment (e.g., workbench frames), interior decoration (e.g.,

shopping mall handrails, ceiling joists), household kitchenware (e.g., range

hood brackets), general outdoor applications (non-coastal areas).

316 Stainless Steel Square Tubes: Coastal

construction (e.g., seaside curtain walls, railings), chemical pipeline

supports, marine aquaculture equipment, medical equipment (e.g., operating room

instrument frames, requiring resistance to disinfectant solutions).

Aluminum Alloy Square Tube: A Preferred

Material for Lightweight Design

Aluminum alloy square tubes use aluminum as

the base material, with added elements such as magnesium (Mg) and silicon (Si).

They combine lightweight design with moderate strength, making them an

important alternative to carbon steel square tubes.

1. Advantages of Aluminum Alloy Square

Tube

Lightweight (density approximately 2.7g/cm³, only 1/3 that of carbon steel), good corrosion resistance (an

oxide film naturally forms on the aluminum surface, requiring no additional

treatment), high thermal conductivity, and aesthetically pleasing appearance

(can be anodized to various colors).

2. Disadvantages of Aluminum Alloy Square

Tube

Lower strength than carbon steel (6061

tensile strength approximately 276MPa), poorer rigidity (easily deformed),

higher price than carbon steel (approximately 10,000-18,000 RMB/ton), and

require specialized aluminum welding technology for welding.

3. Applicable Scenarios for Aluminum Alloy

Square Tube

Applications requiring lightweight

materials: such as aluminum alloy door and window frames, bicycle frames,

luggage handles, and drone frames (relying on their low density).

Decorative and Civil Applications: Such as

interior partitions, advertising light box frames, exhibition display racks

(can be anodized to black, silver, etc., combining aesthetics and corrosion

resistance).

Heat Dissipation Needs: Such as equipment

heat dissipation brackets, automotive cooling system components (utilizing

their high thermal conductivity).

How to Quickly Select Square Tube

Material?

Large Span, Heavy-Duty Structures – Carbon Steel Square Tube (Q355)

Outdoor but Limited Budget – Galvanized Carbon Steel Square Tube

Coastal/Chemical Environments – 316 Stainless Steel Square Tube

Food/Medical Engineering – 304 Stainless Steel Square Tube

Lightweight and Aesthetically Pleasing – Aluminum Alloy Square Tube

FAQ

1. How to determine if square tubes meet

international engineering standards?

Check the material certificate (MTC/EN10204

3.1), dimensional tolerances, weld quality, and request third-party testing

(such as SGS, BV).

2. What are the supply guarantee measures

for square tubes in large-scale engineering projects?

Reputable manufacturers establish dedicated

supply channels, assign project specialists to track shipments, and maintain a

safety stock of at least 30% of the contracted volume to ensure timely supply.

3. How to prevent deformation or corrosion

during the export transportation of square tubes?

Use steel strapping and wooden padding for

isolation. Add moisture-proof materials inside the container. If necessary,

apply rust-preventive oil or VCI packaging.

Read more: The

Benefits of Using Square Tube in Construction

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.