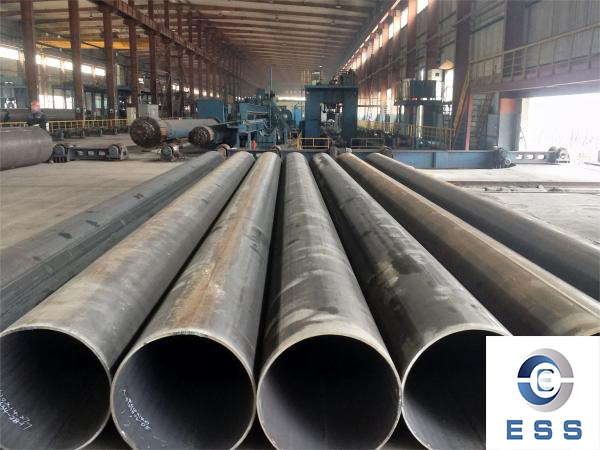

Three types of steel pipes used in long-distance pipelines

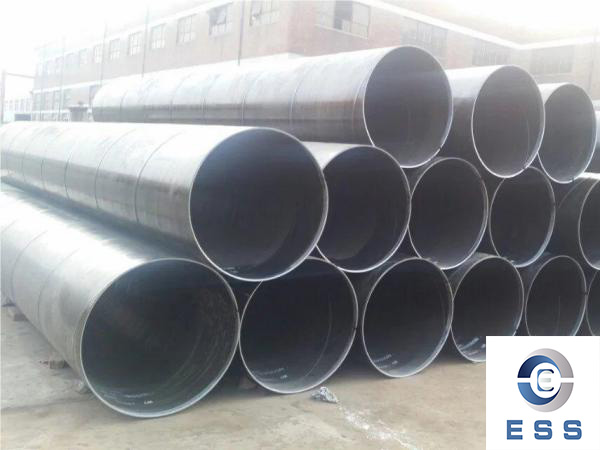

1.SSAW steel pipe

Spiral seam submerged arc welded steel pipe was the earliest application in my country's oil and gas industry and is still widely used. Its main advantages are:

a. The weld seam is distributed in a spiral shape, so that the maximum driving cracking direction of the steel pipe is inconsistent with the direction of the minimum fracture resistance, thereby reducing the risk of pipe cracking along the weld seam direction;

b. The vertical weld direction of the spiral welded pipe is the weak direction of strength, thus avoiding the main stress direction of the steel pipe;

c. The manufacturing process of spiral welded pipe is relatively simple, mature and cheap;

d. It has a long history of use and rich experience and lessons.

But its spiral weld also brings its inevitable shortcomings:

a. During the welding and forming of the spiral welded pipe, a large residual stress is formed, and after the steel pipe is subjected to internal pressure, the tensile stress increases, and the pressure bearing capacity of the steel pipe is obviously weakened;

b. The heat-affected zone of spiral welded pipe is relatively large and has high hardness;

c. The weld seam of the spiral welded pipe is long. Since the defects of the steel pipe mainly occur on the weld seam, the long weld seam means a reduction in reliability;

d. The shape of the weld is not good, which brings difficulties to the coating process inside and outside the steel pipe. Air pockets or leaks often occur on both sides of the weld during the coating process;

e. The accuracy of its geometric dimensions is worse than that of straight seam welded pipes;

f. The Bauschinger effect of spiral welded pipes is large, which reduces the yield limit of steel pipes.

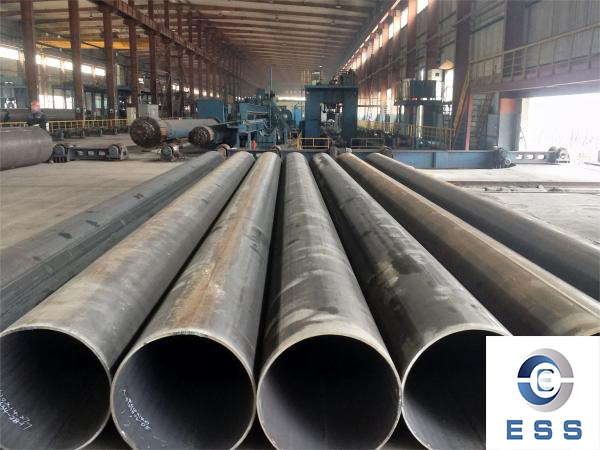

2.LSAW steel pipe

On large-diameter pipelines, the excellent performance of double-sided submerged arc welding has been recognized by countries all over the world, and some countries such as Europe and the United States even regard it as the preferred product. Its main advantages are:

a. The cold expansion process of the full pipe length after welding can be used to expand the pipe, thus eliminating the forming stress and welding stress of the welded pipe.

b. The straight seam double-sided submerged arc welded pipe is welded on a plane, and the weld seam is a straight line, so its welding conditions, online automatic tracking of the weld seam, online ultrasonic testing and X-ray flaw detection are relatively easy to realize.

c. The base material of the straight seam double-sided submerged arc welded pipe is a single controlled steel plate, which can be subjected to 100[wiki]%[/wiki] non-destructive testing.

d. The straight seam double-sided submerged arc welded pipe has high processing precision and is convenient for on-site installation and butt welding of the pipeline.

e. Straight seam double-sided submerged arc welding uses multi-wire welding. The weld seam and the base metal transition smoothly, and air pockets or leakage points are not easily formed on both sides of the weld seam.

f. Short welding seam means improved reliability.

Although straight seam submerged arc steel welding has good overall performance, its high price limits its popular application.

The country already has the ability to produce straight seam double-sided submerged arc welded steel pipes, and production lines with a diameter of more than 1m have been put into production, laying the foundation for future development.

3.ERW pipe

Due to technological advancements in the past decade, the manufacturing process of straight seam high-frequency resistance welded steel pipes has been continuously improved, and its application scope has been rapidly expanded. Its main advantages are:

a. No chemical components are added during the welding process of straight seam high-frequency resistance welded steel pipes, and the welding quality mainly depends on the quality of the base material. In recent years, due to the continuous improvement of the quality of hot-rolled coils, the quality of the welds has also been improved in the process of pipe making. Even if the quality of the welds is slightly insufficient, it will not affect the quality of the entire steel pipe.

b. In recent years, due to the advancement of automation technology, the main parameters of resistance welding can be optimized by computer control, which ensures a substantial improvement in welding quality.

c. Straight seam high frequency resistance welded steel pipe has small residual stress and high strength.

d. The straight seam high-frequency resistance welded steel pipe has high geometric and dimensional accuracy, which is convenient for on-site installation, butt girth welding and anti-corrosion construction.

e. The short weld bead of straight seam high-frequency resistance welded steel pipe means improved reliability.

f. Straight seam high-frequency resistance welded steel pipe has a price advantage, and its price is much lower than that of straight seam double-sided submerged arc welded steel pipe. However, since the straight seam high-frequency resistance welded steel pipe may have insufficient weld quality, external anti-corrosion treatment is required.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.