Small diameter

precision tube

Small-diameter precision pipes are small-diameter seamless pipes with high dimensional accuracy and good surface finish used in mechanical structures and hydraulic equipment.

Small-diameter precision pipes use precision seamless pipes to manufacture mechanical structures or hydraulic equipment, which can greatly save machining hours, improve material utilization, and at the same time help improve product quality. Small-diameter seamless pipes can be divided into hot-rolled pipes, cold-rolled pipes, cold-drawn pipes, extruded pipes, etc. according to different production methods.

Hot-rolled seamless pipes are generally produced on automatic pipe rolling units. The solid tube blanks are inspected and cleared. The surface defects are cut into the required length, centered on the perforated end of the tube blank, and then sent to the heating furnace for heating. The piercing machine is used to pierce the holes while constantly rotating and advancing during the piercing process. Under the action of the rollers and the head, a cavity is gradually formed inside the tube blank. The gross pipe is weighed, and then sent to the automatic pipe rolling machine for continued rolling. Finally, the wall thickness is evened by the leveling machine, and the size is determined by the sizing machine to meet the specification requirements. The use of continuous pipe rolling units to produce hot-rolled seamless steel pipes is a more advanced method. If you want to obtain seamless pipes with smaller size and better quality, you must use cold rolling, cold drawing or a combination of the two methods. Cold rolling is usually carried out on a two-roll mill. Small-diameter seamless pipes are made with variable cross-section circular holes and grooves. Rolling in an annular pass formed by a fixed conical head. Cold drawing is usually carried out on a single chain or double chain cold drawing machine. The extrusion method is to place the heated tube blank in a closed extrusion cylinder. The perforated rod moves together with the extrusion rod to extrude the extruded piece from the smaller die hole. This method can produce steel pipes with smaller diameters.

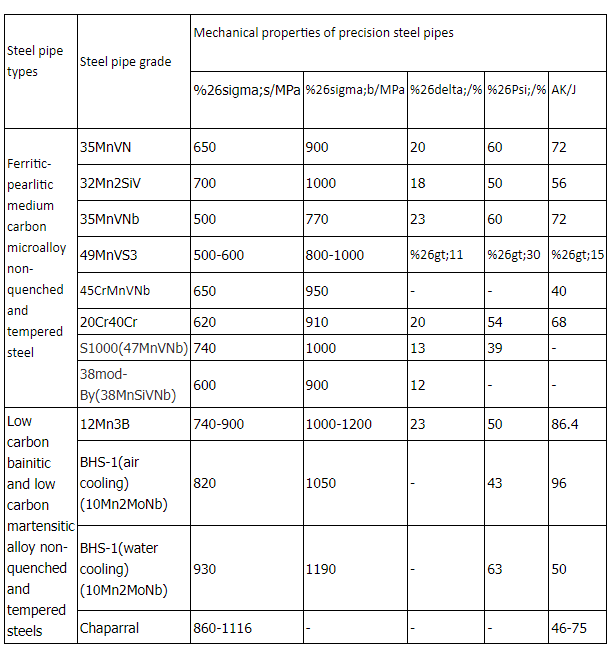

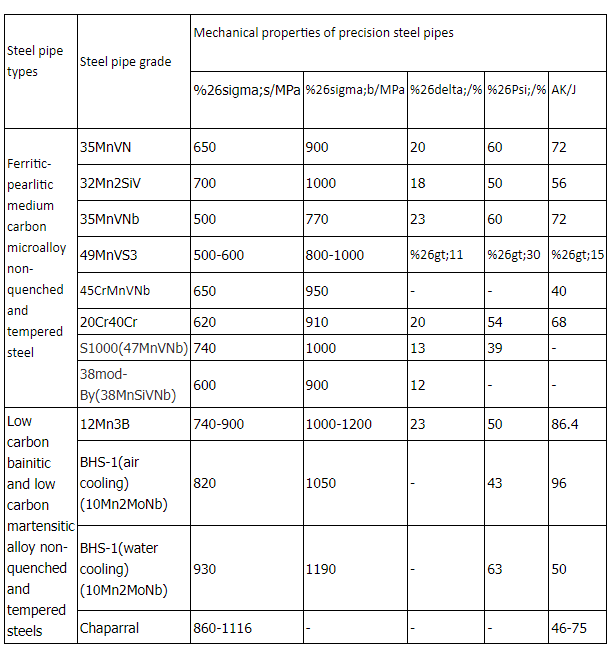

Mechanical behavior

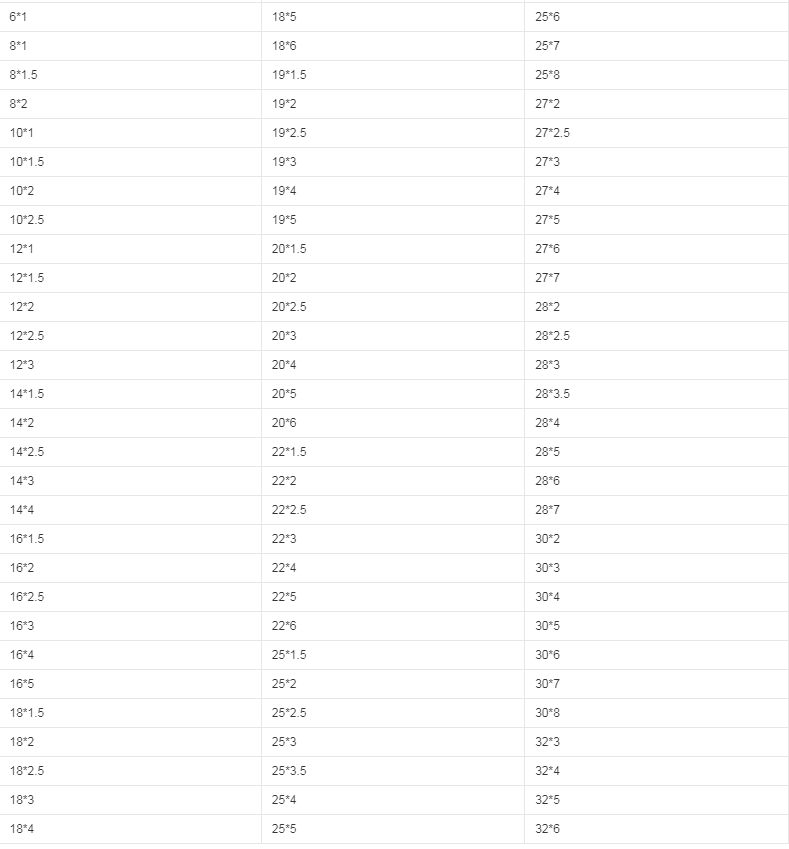

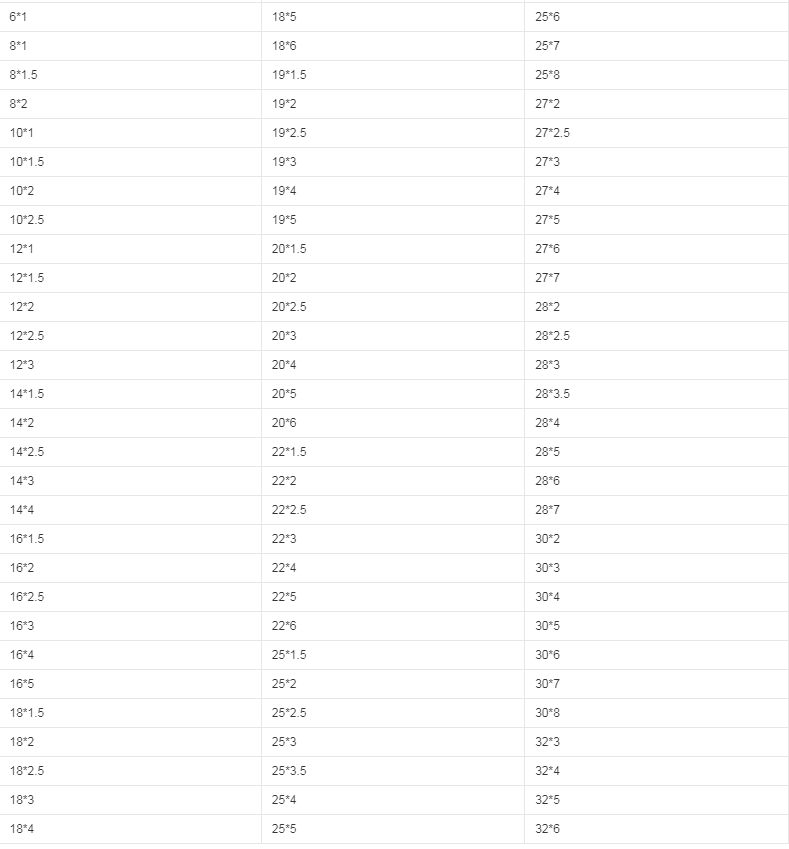

Small diameter precision pipe specification table

Calculation formula

(Outer diameter - wall thickness) X wall thickness X0.02466 = weight kg per meter

Generally speaking, for the specifications of small-diameter precision steel pipes, those with outer diameters between (3mm-89mm) are usually called small-diameter thick-walled precision steel pipes because their diameters are relatively small.

Wall thickness (0.8mm-30mm) can actually be divided into: small-diameter thick-walled precision steel pipes and small-diameter thin-walled precision steel pipes.

Read more: Seamless Steel Pipe Sizes

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.