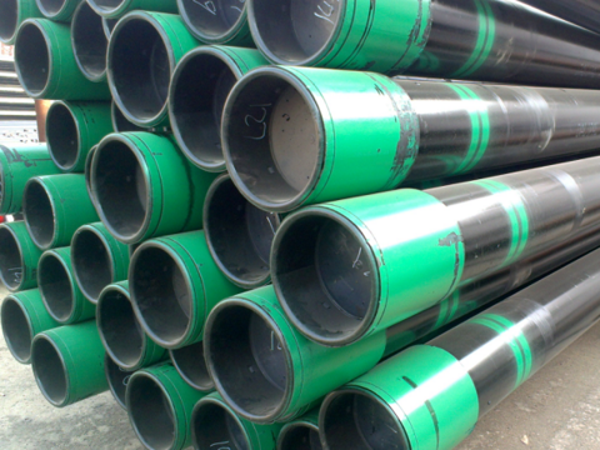

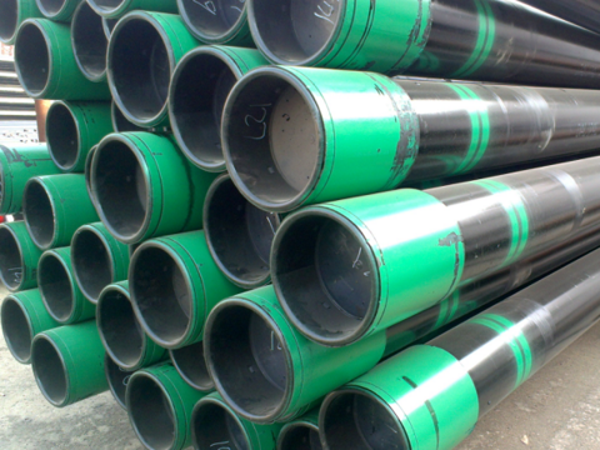

How to choosing the octg casing for your drilling needs?

Octg casing is an essential part of the drilling process, providing structure and strength to boreholes and wellbores. It is important to choose the right casing for your drilling needs in order to ensure maximum efficiency and safety. In this essay, we will discuss the concept of choosing the right octg casing for your drilling needs, from materials to features and back-end considerations. We will also provide some tips and tricks for making a successful selection.

Types of octg casing

The type of casing used in drilling operations is largely determined by the geology of the drilling area and the type of drill being used. Broadly speaking, octg casing can be divided into two categories – steel and thermoplastic. Steel casing is typically used when drilling into rocky terrain or in areas of high pressure, as its strength and durability make it ideal for these types of operations. Thermoplastic casing, on the other hand, is better suited for drilling into softer soils and is more cost-effective in some cases.

Features of octg casing

When selecting octg casing for your drilling needs, it’s important to consider the features that are offered. Some of the features to look for include corrosion resistance, high-pressure tolerance, and heat-resistant properties. Additionally, you should take into account factors such as weight, length, and diameter of the casing. These are all factors that can affect the overall performance of the drill procedure.

Pipe grade

The pipe grade of a given octg casing is an important factor to consider when making your selection. This indicates the steel grade and its strength level. For instance, api 5ct j55 is designed for use in shallow wells and is intended for general conditions of medium-to-low stress. On the other hand, api 5ct p110 has a higher tensile strength and is more suitable for use in deep wells with high-pressure conditions. Be sure to consult with a professional to determine the appropriate grade for your drilling needs.

Length, weight, wall thickness, and threading

In addition to pipe grade, other factors such as length, weight, wall thickness, and threading should also be taken into account when choosing the right octg casing. The length of the casing will depend on the size of the hole being drilled. As for weight, heavier casings provide added stability, while lighter casings tend to be more economical. In terms of wall thickness, the casing should be thick enough to withstand the pressure of the well. Finally, threading is important since it helps to securely connect the casing to the well head and support structure.

Environment

The environmental conditions of the area in which the casing will be used should also be taken into consideration. Depending on the soil, water, and temperature, a certain type of casing may be better suited for a particular drilling site. For example, if the site is located in an area with high amounts of seismic activity, a thicker octg casing may be necessary to ensure stability. Additionally, certain materials may be more corrosion-resistant and therefore better able to withstand salty or acidic environments.

Back-end considerations

In addition to the physical aspects of octg casing, it’s also important to consider the back-end aspects important to your drilling project. This includes things like the cost of the casing, installation time, and any extra services that may be included. All of these factors should be taken into account when making a decision on the right octg casing for your project.

Tips and tricks for choosing the right octg casing

When selecting octg casing, there are a few tips and tricks that can help make the process easier. To start, make sure that you clearly identify the purpose and specifications of the casing so that you can narrow down your search. Additionally, research the different types of casing available to find which one would best suit your needs. Finally, don’t forget to keep the back-end factors in mind – such as cost, installation time, and services included – as these may have an impact on your final decision.

Conclusion

Choosing the right octg casing for your drilling needs is key to ensuring a successful operation. When selecting octg casing, it’s important to consider the various types, features, and back-end considerations, such as cost and installation time. By following the tips and tricks outlined in this essay, you can ensure that you make the right choice for your project.

Read more: What is OCTG Casing? or What are the grades of OCTG casing?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.