Steel is one of the most commonly used

materials in construction engineering, which is no surprise. From its superior

strength to its economy, steel offers numerous benefits to builders and end

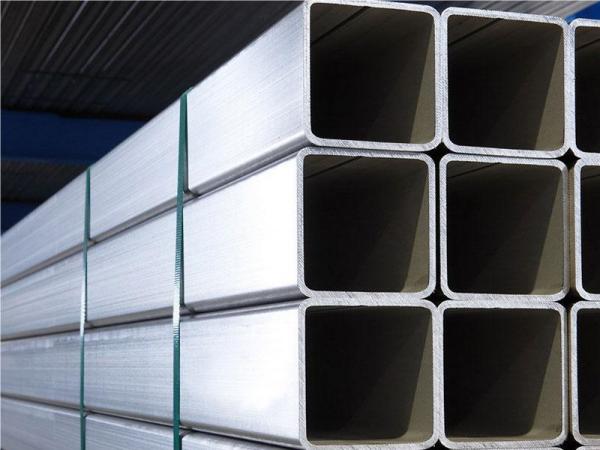

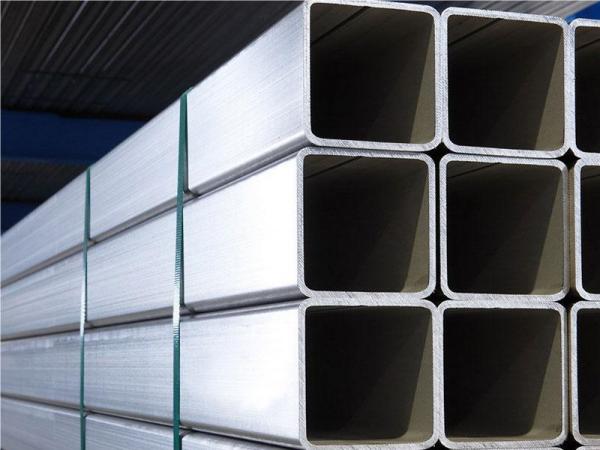

users. However, one type of steel stands out among the many – SHS

steel.

SHS Steel Meaning

SHS steel stands for square tube. It is a

hollow tube commonly found in construction projects that require large

quantities of steel. Due to its superior strength and higher corrosion

resistance, SHS steel has a wider range of applications than other types of

steel.

Common standards include:

|

Standard System

|

Common Standards

|

Note

|

|

Europe EN

|

EN

10210 (Hot Forming), EN

10219 (Cold Forming)

|

SHS Steel for Building and Structural Use

|

|

UK BS

|

BS 5950, BS EN 10305

|

Mechanical and Structural Applications

|

|

USA ASTM

|

ASTM A500, A501

|

Square Tubes for Building Structures

|

|

Australia AS

|

AS 1163

|

High-Strength Structural Square Tubes

|

|

China GB

|

GB/T 6728, GB/T 3094

|

Cold-Formed Square Tubes for Steel

Structures

|

Square Tube Materials

Ordinary square tubes are usually made of

steel, but can also be made of aluminum, copper, or other alloys. The choice of

these materials depends primarily on specific application requirements and cost

considerations.

1. Steel Square Tubes

This is the most common type, widely used

due to its high strength and low cost.

Different types of steel can be selected as

needed, such as stainless steel to improve corrosion resistance.

Common Materials: Q235, Q355, S235, S355,

ASTM A500 Grade B/C

Advantages: High strength, low price, easy

to weld

Applications: Building structures,

machinery, transportation facilities

2. Aluminum Alloy Square Tubes

Although aluminum alloy square tubes are

more expensive, they are lighter, more corrosion-resistant, and easier to

process, making them suitable for certain high-end applications.

Common Materials: 6061-T6, 6063-T5

Advantages: Lightweight (approximately 1/3

the weight of steel), corrosion-resistant, good machinability

Applications: Rail transit, aerospace

components, high-end furniture

Main Applications of Square Tubes

1. Building Structures

Square tubes are commonly used to construct

steel structural frames, roof trusses, curtain wall supports, etc.

2. Machinery Manufacturing

As equipment supports, conveyor tracks, or

the skeleton of automated production lines, square tubes can withstand

high-frequency vibrations and loads.

3. Furniture and Decoration

Modern minimalist style tables, chairs, and

display cases often utilize lightweight square tubes.

The surface can be powder-coated to achieve

various colors without requiring additional rust prevention treatment.

4. Transportation Facilities

Subway station railings, highway sign

brackets, etc., all rely on the weather resistance of square tubes, maintaining

stable performance in environments ranging from -40℃ to

120℃.

Benefits of Using SHS Steel

1. High Structural Strength

The geometry

of SHS steel distributes weight evenly across its four sides, giving it

excellent resistance to bending, compression, and torsion.

This makes it an ideal material for

load-bearing structures, bridges, and heavy-duty frames.

Compared to CHS steel (round

tubes) of the same weight, SHS steel generally offers 10–20% higher bending resistance.

2. Aesthetically Pleasing

The neat appearance and smooth lines of

square tubes not only meet structural requirements but also enhance overall

aesthetics.

3. Lightweight and Durable

Compared to solid steel bars, SHS steel is

lighter in weight while maintaining similar strength.

This makes transportation easier,

installation faster, and costs lower without compromising durability.

4. Excellent Weldability and Machinability

Square hollow profiles have a smooth

surface and uniform wall thickness, making them easy to cut, drill, and weld.

Processors can use them for a wide range of

custom designs, from curved building components to precision engineering parts.

5. Economical and Low-Maintenance

Whether galvanized, painted, or untreated,

square hollow profiles require minimal maintenance.

Their durability reduces the need for

frequent repairs or replacements, saving time and money over the structure's

lifespan.

6. Structural Stability

The quadrilateral design of square tubes

provides excellent stability.

Stability is crucial in construction and

building, ensuring that structures maintain their shape and function under

various environmental conditions.

7. Corrosion Resistance

Many square tubes are made of

corrosion-resistant materials such as stainless steel or galvanized steel,

meaning they can be used for extended periods in harsh environments without

damage.

FAQ

1. When to Use SHS Steel?

SHS steel should be used when projects

require structural components with uniform stress distribution, good bending

and torsional resistance, and a regular appearance.

It is commonly used in building

load-bearing frames, columns, trusses, machinery frames, transportation

facilities, and exposed structural designs.

Especially in scenarios requiring both

strength and aesthetics, SHS is the preferred choice.

2. What Does SHS Steel Mean in

Construction?

In construction engineering, SHS steel

refers to Square Hollow Section.

It is a structural steel tube with a square

cross-section, characterized by high strength, good structural stability, and a

regular appearance.

It is commonly used in columns, beams,

bracing, frames, and curtain wall systems of steel structure buildings.

Conclusion

SHS steel, with its high strength,

aesthetics, ease of processing, and durability, is widely used in construction

engineering, machinery manufacturing, transportation facilities, and furniture

decoration. It not only boasts excellent performance but also offers extremely

high cost-effectiveness, making it an indispensable material in modern

engineering structures.

Read more: SHS

Steel vs RHS Steel or SHS Steel Meaning

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.