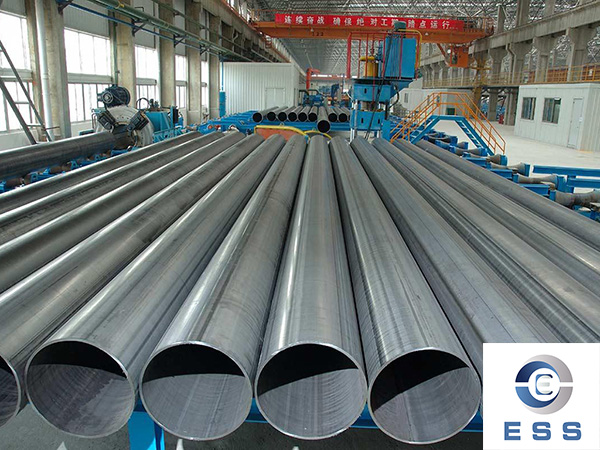

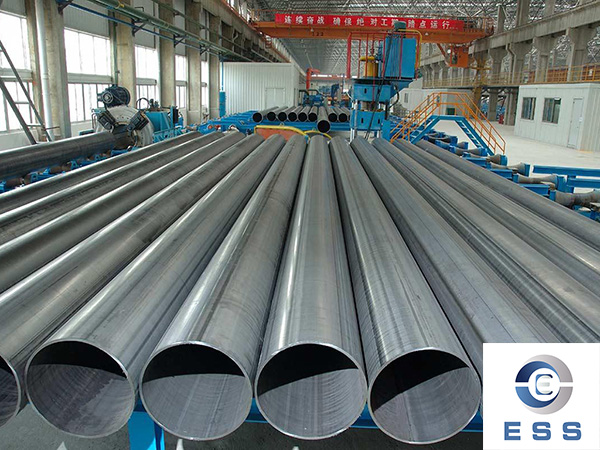

ERW pipe unit, ERW pipe production line

ERW steel pipe/pipe production line is the world's first non-destructive testing technology, with advanced forming technology, high-power welding, full-featured, double-weld heat treatment and full-pipe heat treatment equipment, and computerized whole-process logistics tracking system. The integrated medium diameter longitudinal welded pipe production equipment is one of the most advanced welded pipe production lines in the world. The main equipment is provided by the world's most advanced longitudinal welded pipe equipment manufacturers such as German SMS and MEER, with an annual output of 300,000 tons of line pipe. erw casing, structural pipe (round pipe, rectangular pipe) and other longitudinally welded pipe products.

PMC erw pipe production line

ERW steel pipe machine is a special equipment for producing straight seam welded pipes in metallurgy, construction, transportation, machinery, vehicles and other industries. It uses cold-rolled and hot-rolled steel strips as raw materials, and is cold-rolled and high-frequency welded to produce round tubes, square tubes, and rectangular tubes of required specifications. In the forming process, the "W" forming process is adopted to make the force more reasonable, and the deformation of each rack of the unit is more perfect.

ERW steel pipe machine, the process is to uncoil the steel coil and butt weld the end of the coil in the strip preparation section. The strip is then fed into the accumulator and pulled from the accumulator through the device at a constant speed. Next, the strip is formed into an open tube in a forming unit. It is then welded to the longitudinal seam welded pipe with solid state high frequency welding, then the external burrs are removed and water cooled.

ERW pipe machine working process:

Uncoiling→shear end welding→cage→forming→welding→cleaning→cooling→sizing→flying saw cutting→discharging table→tube collection→packing

Raw material characteristics:

·Pure steel, stable chemical composition, stable steel performance;

·The dimensional accuracy of the coil is high, the shape of the plate is well controlled, and the surface quality of the coil is good.

Online detection technology:

·Ultrasonic plate detection: detect layered defects and longitudinally long defects, and configure defect tracking and painting devices to ensure 100% detection, tracking and removal of plate defects.

·On-line weld seam ultrasonic flaw detection: weld longitudinal and longitudinal defect detection, heat-affected layer detection and internal burr height control, mainly used for production process control.

·On-line flattening test: Sampling at 0°, 90° and pressure direction of the weld seam for flattening test to ensure the basic performance requirements of the weld seam.

·Hydrostatic test: provide tightness guarantee for the base metal and weld seam of each steel pipe.

Off-line ultrasonic flaw detection of weld seam: magnetic particle flaw detection of pipe end and groove surface, artificial ultrasonic flaw detection of pipe end, finished product size detection.

ERW pipe manufacturing process:

Converter steelmaking→outside refining→continuous casting→hot rolling→coiling→strip flattening→head cutting→butt welding→spiral looper→edge washing→strip ultrasonic flaw detection→forming→high frequency welding→on-line welding ultrasonic flaw detection→ On-line weld seam heat treatment→air cooling, water cooling→sizing→flying saw segmentation (flattening test)→pipe end chamfering→hydraulic test→weld seam ultrasonic flaw detection→pipe end flaw detection→appearance dimension inspection→length measurement and weight→punching Labeling→Coating→Packaging→Factory

ERW steel pipe has the characteristics of relatively simple process and fast continuous production speed, and is widely used in civil construction, petrochemical, light industry and other fields.

It is mostly used to transport low-pressure fluid or manufacture various engineering components and light industrial products.

ERW steel pipe is based on the principle of electromagnetic induction and the skin effect, proximity effect and eddy current heating effect of the AC charge in the conductor, so that the steel at the edge of the weld is locally heated to a molten state, and the butt weld is crystallized indirectly by roller extrusion. So as to achieve the purpose of welding seam welding.

ERW steel pipe is a type of induction welding. No weld filler is required, no welding spatter, narrow welding heat affected zone, beautiful weld shape, and good welding mechanical properties. Therefore, it is widely used in steel pipe production.

Read more: ERW Pipe Specifications and Models or Seamless pipe vs erw pipe

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.