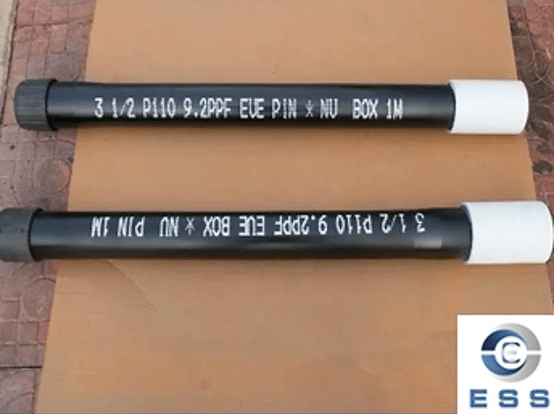

Threaded pup joints are commonly used accessories in industrial pipeline connections. They are

mainly used to connect pipelines. They are easy to install and disassemble and

can withstand high pressure. The surface of the threaded pup joints is flat,

crack-free, and has no obvious defects such as pores and inclusions, making

them highly durable and reliable.

Main types

1. Single-end threaded pup joints: One end is externally threaded

and the other end is flat or beveled. This pup joint is convenient to install

and disassemble, suitable for various high-pressure fluid pipelines and

equipment, and can withstand high pressure.

2.

Double-end threaded pup joints: Both ends are externally threaded. This pup

joint is also suitable for high-pressure fluid pipelines and equipment, with a

high cost-effectiveness, a flat surface, no cracks, no obvious defects such as

pores and inclusions, and is durable.

Installation and disassembly

1. Installation method: Screw one end of the

threaded pup joint into one end of the pipe to ensure that the threads are

aligned; use an appropriate torque wrench or wrench to tighten the connection

to ensure that the connection is firm; check whether there is leakage at the

connection and seal it if necessary.

2. Disassembly method: Use an appropriate wrench

or torque wrench to rotate the threaded pup joint counterclockwise to loosen

the connection; ensure that excessive force is not applied during the

disassembly process to avoid damaging the threads or connecting parts; check

whether the connecting parts after disassembly are damaged or worn, and replace

or repair them if necessary.

Maintenance and care

1. Regular inspection: Regularly check whether there is leakage or looseness at the

connection of the threaded pup joint to ensure a firm connection.

2. Cleaning and maintenance: Regularly clean the

threaded pup joint and connecting parts to prevent impurities or dirt from

affecting the connection effect.

3. Lubrication: Lubricate the threads when necessary to reduce friction and wear.

4. Replace damaged parts: If the threaded pup joint

or connecting parts are found to be damaged or worn, they should be replaced in

time to ensure the reliability and safety of the connection.

How to choose a threaded pup joint

1. Choose the right material according to

the application and medium;

2. Choose a threaded pup joint that meets

the standards according to the pressure of the pipeline and system;

3. Consider the connection method, and

choose internal thread, external thread or pipe insertion threaded pup joint

according to the needs;

4. Pay attention to the outer diameter and

length of the threaded pup joint to ensure that it meets the requirements after

connection.

Summary

Threaded pup joints are mainly divided into

single-end and double-end. By understanding the relevant types of threaded pup

joints, installation and disassembly methods, and how to maintain and maintain

them, we can better help us choose and use threaded pup joints to ensure the

safe and stable connection of pipelines and equipment.

Read more: Threaded Pup Joint Usage Guide or How To Choose A Threaded Pup Joint?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.