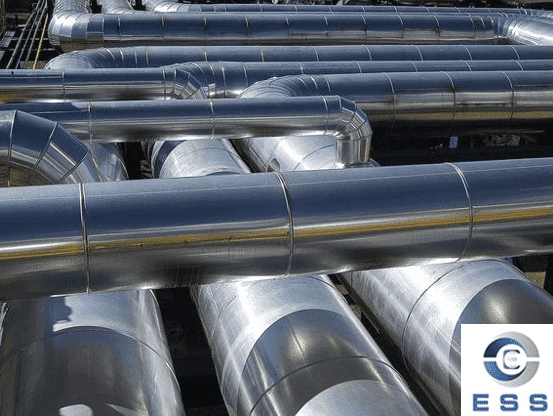

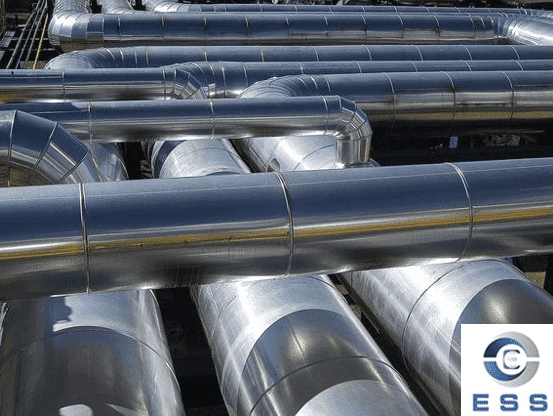

Boiler

tube refers to steel with two ends open and hollow sections, and its length

is relatively large compared to the surrounding area. It can generally be

divided into seamless

steel pipe and welded

steel pipe. Boiler tubes can be used for pipelines, thermal equipment,

mechanical industry, petroleum geological exploration, containers, chemical

industry and special purposes.

Boiler tube overheating refers to the phenomenon

that the metal tube wall temperature of the heating surface or the outlet steam

temperature exceeds its rated value during the operation of the boiler. This

phenomenon may cause unstable boiler operation and even cause safety accidents

and other hazards.

Causes of overheating

1. Insufficient drainage and exhaust volume at startup: During the

boiler startup process, if the drainage and exhaust volume are insufficient and

the load increase speed is too fast, the superheater heating surface will be

insufficiently cooled, causing the tube wall metal to overheat.

2. Improper use of cooling water adjustment: Improper adjustment of

cooling water will lead to inaccurate control of the superheater tube wall

temperature. If the cooling water is used improperly, the tube wall temperature

will be too high.

3. Poor quality of steam and water: During

boiler operation, if the chemical treatment of boiler water is improper or

chemical supervision is not strict, it will cause scaling in the superheater

tube, affecting the heat transfer effect, thus causing overheating of the tube

wall.

4. Improper combustion control: Improper

combustion control will lead to problems such as flame upward movement, high

flue gas temperature at the furnace outlet, and large thermal load deviation,

which will cause overheating of the heating surface.

5. Insufficient air volume: Insufficient air volume

will lead to incomplete combustion, secondary combustion in the flue, and then

overheating of the heating surface.

6. Local ash and coking in the flue: Local

ash and coking in the flue will hinder the flow of flue gas, resulting in local

overheating of the heating surface.

7. Unreasonable design of the heating surface: Unreasonable design of the heating surface, such as improper

design of tube row spacing, flue gas flow rate, etc., will lead to local

overheating.

8. Temperature distortion of wall temperature measuring point: Temperature distortion of wall temperature measuring point will

affect the monitoring and control of tube wall temperature, thus causing

overheating.

Hazards of overheating

1. Equipment damage: High temperature can cause the performance of

metal materials to deteriorate and even cause equipment damage.

2. Safety accidents: Long-term overheating will increase the risk of

boiler explosion.

3. Reduced operating efficiency: Overheating will affect the heat

exchange efficiency of the boiler, resulting in increased operating costs.

Preventive measures

1. Strictly control the startup and load increase speed of the

boiler: During the startup of the boiler, the operation should be strictly

carried out in accordance with the temperature increase and pressure increase

curve, and the combustion should be reasonably adjusted to control the load

increase speed to avoid thermal deviation.

2. Reasonable use of cooling water: During operation, the cooling

water at each level should be reasonably used to reduce the steam temperature

at the front end of the superheater as much as possible, strengthen the heat

absorption capacity of the pipe, and avoid overheating of the pipe wall.

3. Strengthen water quality management: Regularly check and adjust

the water quality to ensure that the boiler water quality meets the

requirements and avoid scaling in the pipe.

4. Optimize combustion control: By optimizing combustion control,

ensure flame stability, avoid flame upward movement and excessive flue gas

temperature at the furnace outlet.

5. Clean the flue regularly: Clean the ash and coke in the flue

regularly, keep the flue unobstructed, and reduce local overheating.

6. Improve the design of the heating surface: Adjust the design of

the heating surface according to the actual situation to ensure that the flue

gas flow rate and the spacing between the tubes are reasonable.

7. Check the wall temperature measurement

points regularly: Check the accuracy of the wall temperature measurement points

regularly to ensure the authenticity of the monitoring data.

Summary

In order to ensure the safe, efficient and stable operation of the

boiler, we need to strengthen the daily maintenance of the boiler, improve the

boiler combustion technology, and improve the water quality and water flow.

Only in this way can we ensure the normal operation of the boiler and ensure

production safety.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.