Anti-corrosion measures for OCTG casing

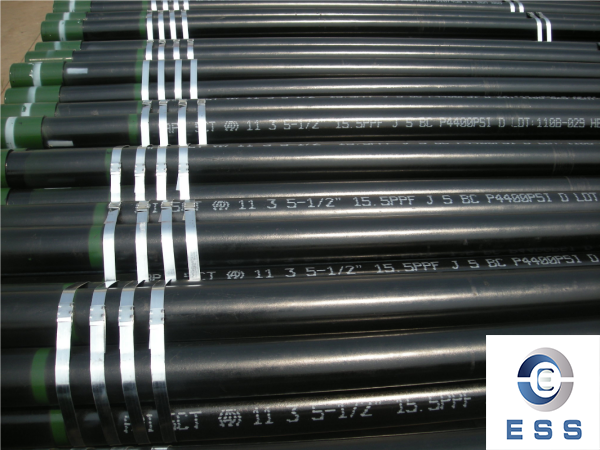

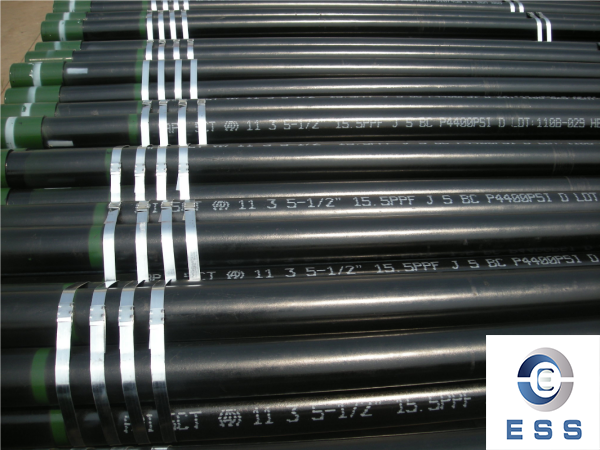

Types of OCTG casing

Different types of casing used in oil extraction: Surface oil casing protects the well from contamination of shallow water and gas formations, supports wellhead equipment and maintains the weight of other layers of casing. Technical oil casing separates pressures at different levels to allow for normal flow of drilling fluids and to protect the production casing.

In order to install anti-burst devices, anti-leak devices and tail pipes in the drilling well. Reservoir oil casings carry oil and natural gas from reservoirs beneath the earth's surface. Used to protect drilling wells and layer drilling mud. When producing oil casing, the outer diameter usually ranges from 114.3 mm to 508 mm. Protect drilling wells from contamination of shallow water and gas zones, support wellhead equipment and maintain the weight of other layers of casing.

Technical oil casing separates pressures at different levels to allow for normal flow of drilling fluids and to protect the production casing. In order to install anti-burst devices, anti-leak devices and tail pipes in the drilling well.

Reservoir oil casings carry oil and natural gas from reservoirs beneath the earth's surface. Used to protect drilling wells and layer drilling mud. When producing oil casing, the outer diameter usually ranges from 114.3 mm to 508 mm. The types and packaging of petroleum casing are divided into two types according to SY/T6194-96 "Petroleum Casing": short threaded casing and its couplings and long threaded casing and its couplings.

The structure of OCTG casing

Weight calculation: [(outer diameter-wall thickness)*wall thickness]*0.02466=kg/meter (weight per meter)

Chemical composition

(1) According to the provisions of SY/T6194-96. The casing and its couplings are of the same steel grade. Sulfur content <0.045%, phosphorus content <0.045%;

(2) Take chemical analysis samples according to the provisions of GB/T222-84. Conduct chemical analysis according to the relevant provisions of GB223;

(3) American Petroleum Institute APISPEC5CT1988 1st edition regulations. Chemical analysis was carried out according to the latest version of ASTME59 for sample preparation and chemical analysis according to the latest version of ASTME350.

Physical properties

(1) According to the provisions of SY/T6194-96. Conduct flattening test (GB246-97), tensile test (GB228-87) and hydraulic pressure test;

(2) Hydrostatic pressure test, flattening test, sulfide stress corrosion cracking test, hardness test (conducted according to the latest version of ASTME18 or E10), tensile test, and transverse impact test ( ASTMA370, ASTME23 and the latest version of relevant standards), grain size determination (ASTME112 latest version or other methods).

Anti-corrosion measures for OCTG casing

1. First, ensure that water quality meets standards and strictly monitor and manage water quality. Implement separate cleaning and injection, strengthen the cleaning work of main water pipelines, ensure that the water quality in the station and at the bottom of the well meets the standards, and reduce the introduction of corrosion sources into the annular space;

2. For water injection wells that have been newly put into production, use annular protection fluid mainly for sterilization, and form a system to add it regularly;

3. In view of the acceleration effect of mechanical scratches on the corrosion of oil casing, it is recommended to add a rubber ring to the coupling of the oil pipe or a centralizer to the severe deviation of the well to prevent the oil pipe from scratching the casing and during the water injection process. One side contacts the casing;

4. In view of the severe bacterial corrosion under the scale and the slow growth and killing of SRB at high temperatures, high-temperature water or water vapor of 100 degrees Celsius can be regularly injected into the annulus to kill the SRB under the scale;

5. Before the corrosion in the water injection well casing is effectively controlled, it is not recommended to promote the use of cathodic protection and coated casing.

Read more: The causes of OCTG casing stuck or What are the grades of OCTG casing?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.