What is the difference between seamless steel pipe and traditional pipe?

1. Compared with other traditional pipes, seamless steel pipe supply steel pipe has lighter material, higher strength, good toughness, can withstand higher internal pressure, flexible production and application, and can adapt to complex or harsh geological conditions.

2. However, there are relatively large defects in the use of steel pipes, mainly due to the trouble of internal and external anti-corrosion treatment. First of all, the problem of external anti-corrosion is very critical, and the quality of external anti-corrosion directly affects its service life. At present, the external anti-corrosion of domestic steel pipes is mainly: concealed method, all steel pipes are required to be reinforced or extra-reinforced external anti-corrosion, and cathodic protection is promoted in some areas.

Concealed external anti-corrosion methods are usually paints such as petroleum asphalt, epoxy coal tar pitch, etc. The latter is not easy to solidify at low temperature, and there are more doubts in the field welding joint construction. This chlorosulfonated polyethylene has been used before. Because there are too many solvents, it is easy to produce pinholes, and the resistance to breakdown is unqualified, and some areas are clearly not used. For cathodic protection, its anti-corrosion effect is better, but because of the sacrificial anode method, the anode must be replaced regularly in future operation, which increases the operating cost and work.

Besides the problem of inner wall treatment, there are three commonly used methods for the supply of seamless steel pipes: anti-corrosion coatings, resin mortar, and cement mortar. There are two problems in all three methods: the first is the problem of the bond strength between the anti-corrosion layer and the steel pipe, which has been mentioned above with cement mortar. For both anti-corrosion coatings and resin mortar, both the inner and outer surfaces of the steel pipe are required to be completely derusted before construction, but it is difficult to be perfect.

Therefore, the rust part will form the source of delamination and peeling in the future, forming corrosion and scaling; secondly, most of the steel pipes are butt-welded on site, and anti-corrosion is carried out after welding. Can only be done manually. The quality is not easy to control, and, regarding the pipes with smaller diameters, because personnel cannot enter the construction, they are no longer anti-corrosion. It also creates a hidden danger of weld damage in the future. According to the analysis of several pipe explosion accidents of steel pipes, it is mainly caused by weld corrosion with poor weld quality.

3. Poor hydraulic performance and high energy consumption. The internal roughness coefficient of the steel pipe is between 0.013-0.014. In this way, for the same water delivery and equal pipe diameter, the resistance along the way is high, and the head of the pump needs to be increased, which increases the investment in the early stage. At the same time, the operating cost is due to consumption. The power is large, and it has also increased significantly.

Application treatment method of seamless steel pipe

1. Grinding of the seamless steel pipe nozzle: After cutting, the plastic layer of the nozzle should be polished with an angle grinder. The purpose is to avoid melting or even burning of the plastic layer during flange welding to damage the pipe. Use an angle grinder to grind the nozzle plastic layer.

2. Plastic-coating treatment of seamless steel pipe: After grinding, use oxygen and C2H2 to heat the nozzle outside the pipe until the inner plastic layer melts, and then the skilled workers will evenly coat the nozzle with the prepared plastic powder , it should be noted that it must be applied in place, and the plastic coating of the flange should be applied above the water stop line.

This process should strictly control the heating temperature. If the temperature is too high, bubbles will be generated during the plastic coating process. If the temperature is too low, the plastic powder will not be completely melted during the plastic coating process. All of the above situations will produce plastic after the pipeline is put into use. The phenomenon of layer peeling, and finally the seamless steel pipe part of the pipeline is corroded and damaged.

3. Cutting of seamless steel pipes: according to the actual required length of pipelines, metal saws and toothless saws should be used to cut the pipes. When using water welding in the cutting process, there must be protection methods for the raw materials. When cutting, fireproof and heat-resistant materials should be used as baffles at both ends of the fracture to catch the sparks and hot molten iron beans that fall during cutting, so as to protect the raw materials. The original plastic layer.

4. Seamless steel pipe connection: After plastic repair, connect and install the pipe and pipe fittings. During the connection process, add rubber pads between the flanges, and tighten the bolts to a sealed state.

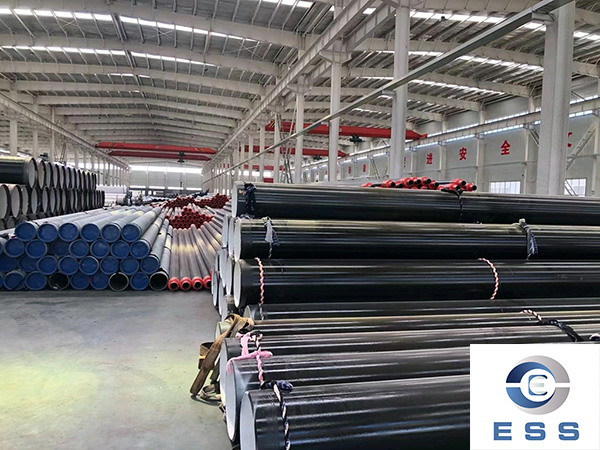

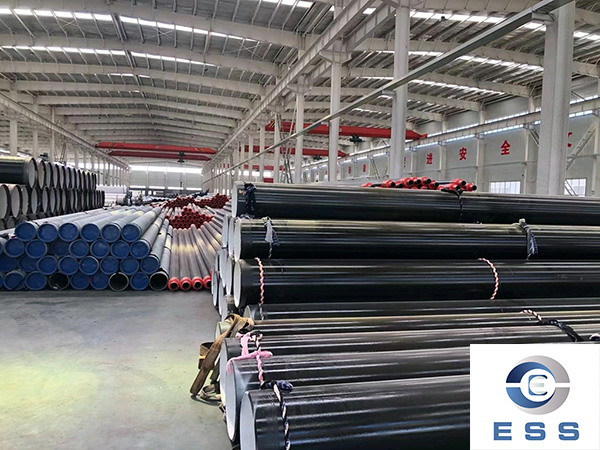

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.