In hydraulic systems, the seamless

pipe is key transmission component, and its material properties directly

affect the safety and efficiency of the system. According to different working

environments and application requirements, there are mainly the following types

of seamless pipes for hydraulic systems:

Carbon steel seamless pipes

1. #10 and # 20 steel seamless pipes

These two types of seamless pipes have

certain strength and good machinability, and the price is relatively

economical. They are widely used in general hydraulic systems and can withstand

medium pressure. For example, some small hydraulic equipment, machine tool

hydraulic systems, etc. often use # 20 steel seamless pipes as hydraulic

tubes.

2. # 45 steel seamless pipes

It has high strength and can be used in

hydraulic systems that withstand higher pressures. However, its welding

performance is relatively poor, and it is generally connected by threaded

connection or high-precision flange connection. It may be used in some medium and high-pressure hydraulic systems,

such as engineering machinery hydraulic systems.

Alloy steel seamless pipe

1. 15CrMo, 12Cr1MoV and other low alloy

high strength steel seamless pipes

It has high strength and good heat

resistance, suitable for high temperature and high pressure hydraulic systems.

For example, in the hydraulic systems of some large industrial equipment, such

as metallurgical equipment hydraulic systems, this type of alloy steel seamless

pipe may be used.

2. 35CrMo, 42CrMo and other medium carbon

alloy steel seamless pipes

It has high strength and good toughness,

and can withstand large loads and pressures. At the same time, it has good

hardenability and machinability. It is more common in some hydraulic systems

with high strength requirements, such as heavy machinery hydraulic systems. Its

manufacturing process is similar to that of mild

steel tube, but it is superior in strength and durability, and is suitable

for long sections and custom lengths of pipe installation.

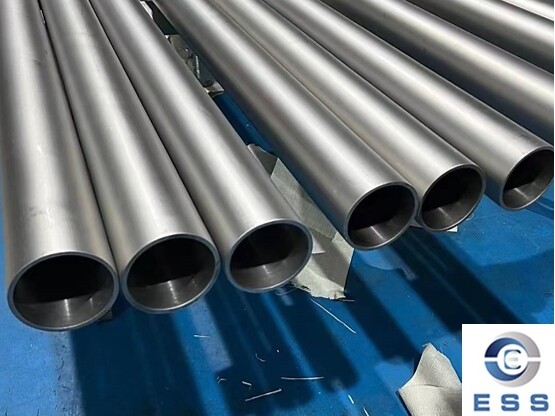

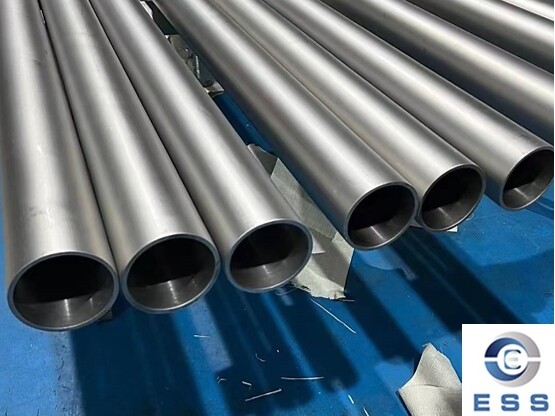

Stainless steel seamless pipe

1. 304 stainless steel seamless pipe

It has good corrosion resistance, oxidation

resistance and processing performance. It is suitable for hydraulic systems

that require corrosive media, or for use in hydraulic equipment in industries

such as food and medicine. For example, in the hydraulic system of some food

processing machinery, 304 stainless steel seamless pipes are used to avoid food

contamination.

2. 316L stainless steel seamless pipes

It has stronger corrosion resistance,

especially in environments containing corrosive media such as chloride ions. At

the same time, it has good welding performance and low temperature performance.

It is widely used in hydraulic systems in marine engineering, chemical industry

and other fields.

Summary

When selecting a suitable seamless pipe for

a hydraulic system, various factors such as working pressure, temperature,

medium characteristics and installation method should be considered

comprehensively. Whether it is carbon steel, alloy steel or stainless steel

seamless pipe, each material has its unique advantages and applicable

scenarios. Reasonable selection can not only improve the safety and efficiency

of the system, but also provide solid guarantee for the long-term stable

operation of the equipment.

Read more: Seamless pipe weight calculation formula

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.