Understanding the Role of Seamless Elbows in Piping Systems

In the realm of piping systems, various components play critical roles in ensuring the efficient and reliable transport of fluids or gases. One such component is the elbow, a fitting designed to change the direction of flow within a piping system. Elbows come in different forms, but one type that stands out for its superior performance and reliability is the seamless elbow. In this article, we will delve into the world of seamless elbows, exploring their construction, advantages, applications, and considerations for installation. By gaining a deeper understanding of the role of seamless elbows in piping systems, engineers and professionals can make informed decisions to optimize system performance and longevity.

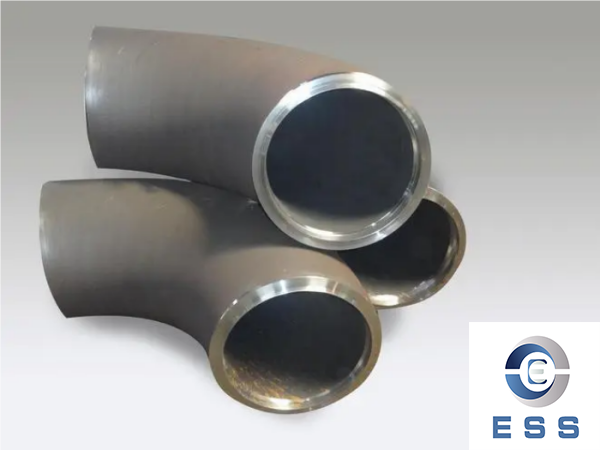

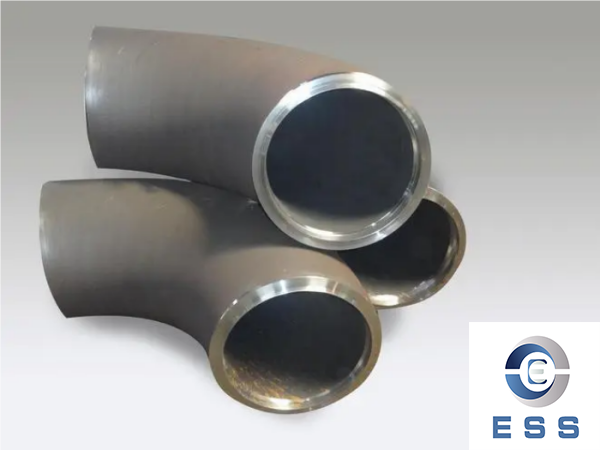

1.Seamless Elbow Construction

Seamless elbows are pipe fittings that are manufactured without a seam or weld in the curvature, allowing for a smooth and continuous flow path. These elbows are typically fabricated from a single piece of pipe or tube, ensuring uniformity and strength throughout the structure. The absence of a weld seam eliminates the risk of leakage or failure at the joint, making seamless elbows highly reliable in demanding applications.

Seamless elbows are commonly made from materials such as carbon steel, stainless steel, alloy steel, or other specialized alloys based on the specific requirements of the piping system. They are manufactured using various processes, including hot extrusion, cold extrusion, or forging, to achieve the desired shape and dimensions. The manufacturing process ensures that the internal and external surfaces of the elbow maintain consistent thickness and smoothness, facilitating efficient fluid flow and minimizing pressure drop.

2.Advantages of Seamless Elbows

2.1 Enhanced Flow Characteristics

The absence of a weld seam in seamless elbows ensures a smooth internal surface, minimizing frictional losses and pressure drop. This characteristic allows for improved flow characteristics, reducing energy consumption and optimizing system performance. The smooth bore of seamless elbows also mitigates the risk of sedimentation, scale buildup, or blockages, which can hinder fluid flow and affect system efficiency.

2.2 Strength and Reliability

Seamless elbows are renowned for their high strength and reliability. The absence of a weld seam eliminates a common point of weakness in conventional welded elbows. The uniform structure of seamless elbows ensures superior resistance to internal and external pressure, mechanical stresses, and thermal variations. As a result, seamless elbows are less prone to leakage, fatigue failure, or premature degradation, contributing to the overall integrity and longevity of the piping system.

2.3 Versatility

Seamless elbows are available in a wide range of sizes, angles, and radii, offering versatility in design and installation. They can accommodate various piping configurations, allowing engineers to optimize system layouts to meet specific project requirements. The versatility of seamless elbows makes them suitable for a broad range of industries, including oil and gas, petrochemicals, power generation, water treatment, pharmaceuticals, and many others.

3.Applications of Seamless Elbows

3.1 Oil and Gas Industry

The oil and gas industry extensively employs seamless elbows due to their ability to withstand high-pressure environments and corrosive fluids. They are commonly utilized in pipelines for oil and gas transmission, refining processes, offshore platforms, and subsea installations. Seamless elbows ensure reliable and uninterrupted flow of hydrocarbons, contributing to the safety and efficiency of the entire system.

3.2 Chemical and Petrochemical Industry

In chemical and petrochemical plants, where a wide range of corrosive and hazardous fluids are handled, seamless elbows offer exceptional chemical resistance and durability. They are used in processes such as chemical synthesis, distillation, fractionation, and reaction systems. Seamless elbows provide reliable connections between different components, ensuring the integrity of the piping system and preventing leaks or contamination.

3.3 Power Generation

Seamless elbows play a crucial role in power generation facilities, including thermal power plants, nuclear power plants, and renewable energy installations. They are utilized in the piping systems for steam, water, or gas distribution, allowing for efficient and controlled flow within the power generation cycle. The high strength and reliability of seamless elbows contribute to the safety and uninterrupted operation of power generation facilities.

4.Considerations for Seamless Elbow Installation

4.1 Material Selection

Choosing the appropriate material for seamless elbows is crucial to ensure compatibility with the fluid or gas being transported and the environmental conditions of the application. Factors such as corrosion resistance, temperature resistance, and mechanical properties should be carefully evaluated to select the most suitable material for the specific operating conditions.

4.2 Proper Sizing and Orientation

Seamless elbows are available in various angles, radii, and diameters. Selecting the correct size and orientation of the elbows is essential to minimize pressure drop and maintain an efficient flow within the piping system. Improper sizing or orientation can lead to increased energy consumption, reduced system performance, or even system failures.

4.3 Quality and Standards

When procuring seamless elbows, it is essential to ensure that they comply with relevant industry standards and specifications. Adhering to recognized standards guarantees the quality, performance, and reliability of the elbows, ensuring they meet the necessary safety requirements.

4.4 Installation and Maintenance

Proper installation techniques are critical for seamless elbows to function optimally. Following recommended procedures and guidelines for installation, including proper alignment, anchoring, and joint sealing, is essential to prevent leaks, stress concentrations, or misalignments. Regular maintenance and inspection should also be performed to detect and address any potential issues before they escalate into significant problems.

Conclusion

Seamless elbows are indispensable components in piping systems, providing reliable and efficient flow direction changes. Their construction from a single piece of pipe or tube, absence of weld seams, enhanced flow characteristics, and versatility make them ideal for various industries and applications. By understanding the role of seamless elbows and considering the factors involved in their installation, engineers and professionals can optimize the performance, reliability, and longevity of piping systems in diverse fields such as oil and gas, chemical and petrochemical, and power generation.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.